Heavy-duty peristaltic or hose pumps combine precise positive displacement and low maintenance requirements with the ability to handle abrasive and aggressive fluids, which wear out many other pump types.

Heavy-duty peristaltic or hose pumps combine precise positive displacement and low maintenance requirements with the ability to handle abrasive and aggressive fluids, which wear out many other pump types. This unique combination of features often proves to be a cost-effective alternative for difficult pumping applications.

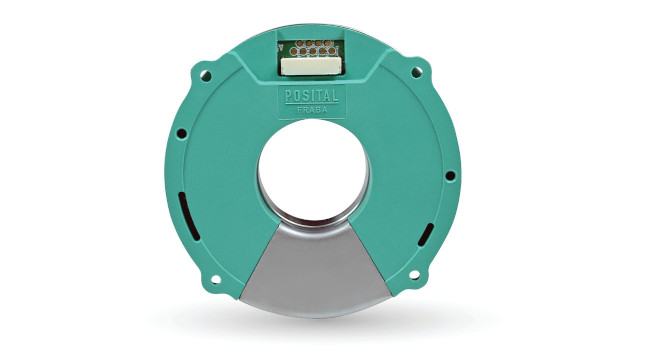

The basic peristaltic principle is widely known. A smooth-wall, flexible hose is rolled and squeezed along a predetermined length, positively displacing the fluid contained within the hose. The hose pump employs a drive-coupled rotor with mounted shoes, which continually compress and occlude some portion of the hose. This action moves the fluid through the hose with a constant rate of displacement for each revolution of the rotor, providing a precise volume of fluid pumped through the hose.

In the past, the fundamental problem in applying peristaltic technology to industrial applications was the development of a hose element which could accommodate the high pressures and flow rates demanded by process industries, along with the capacity to handle highly abrasive and chemically aggressive fluids. The latest hose design is triple-layered with an inner layer surrounded by a reinforcement cord matrix, and durable, machined outer layer.

Shoes with profiled leading and trailing edges give a gradual lead-in and termination to each hose occlusion. This arrangement prevents an abrupt imposition and release of pressure and significantly increases hose life. A specially developed lubricant contained within the pump head reduces hose wear as a result of contact with the pressing shoes.

A direct-coupled pump assembly — a compact design easy to install — reduces bearing loads and simplifies hose changes. Bearings are incorporated in the pump head itself, and a gearbox plugs into the pump head. This innovation offers gearbox and motor protection, as well as reducing overall assembly and subsequent maintenance time.

Hose pumps have been successful in replacing traditional types in abrasive handling applications. A traditional pump typically has the rotor and stator in the product zone. Abrasive particles in the product zone quickly open up critical tolerances between the rotor and stator, causing a drop-off in pumping efficiency and eventual failure. Traditional positive displacement pumps require tight tolerances to function.

A hose pump rotor is out of the pumped-product zone. The hose is the only part to touch the product, keeping abrasive pump wear to a minimum. A properly selected heavy-duty pump hose does not fail due to abrasive wear; it fails due to the number of compressions and operating pressure. Regardless of product, whether it is abrasive lime slurry or nonabrasive polymer, the hose life is the same.

Metering

By design, hose pumps are positive displacement, and can be used in applications where accurate volumetric control of the pumped fluid is important. This metering capability has become one of the primary functions of the hose pump in industrial applications. One of the keys to metering accuracy and repeatability is the restitution of the hose. With a properly constructed and maintained hose the pump can deliver fluid with an accuracy to 1% and a total accuracy decline, over the life of the hose, of approximately 3%.

Variable speed offers the capability of changing volumetric output by altering rotor speed, with the hose maintaining a constant rate of volumetric displacement. Since hose life is dependent on rotor speed and process pressure, a life of thousands of hours is not uncommon in many applications. Once a typical hose life is established for a particular application, a predictive maintenance schedule for hose changes ensures continued metering accuracy with no unexpected downtime.

A hose pump alone can handle many processes previously controlled by a combination of pumps and flowmeters, resulting in a considerable saving on equipment costs. High concentrations of caustic materials or particulate matter can attack the wetted parts of a flowmeter and affect the reliability of measurement. If the hose material is chemically compatible, the fluid does not affect the metering accuracy of the pump.

Typical metering applications involve processes that require a controlled release of product while moving it from one area to another. For example, effluent treatment from an industrial treatment plant often involves the addition of a variety of chemicals to the process in regular, controlled doses. A hose pump can handle these often corrosive and aggressive compounds without damaging the pump, and release them in precise quantities into the process stream.

Applications

Maintaining a chemical balance through varying process conditions often requires that the dosage may fluctuate, which can be accomplished with a variable speed hose pump without sacrificing metering accuracy. Mixing applications often require precise combinations of additive metering as part of the process. In cases where one or more additives are highly viscous or have a high solids content, hose pumps perform without the high maintenance costs associated with other types.

Hose pumps are well suited for filling applications. Substances susceptible to detrimental damage or emulsification when pumped, such as fruit pieces, latex, or yeast, can be transferred and metered through a hose pump without affecting product quality. In many of these applications the hose pump’s clean-in-place capability is a factor when selecting the best type for the application.

With the capability of handling fluids deleterious to other pump types, the hose pump has found a niche as a problem solver for many difficult problems. While the total cost-of-ownership for processing equipment is becoming a significant factor in the choice of equipment, this pump addresses the needs of the process industries by eliminating flowmeters and reducing maintenance.

— Edited by Joseph L. Foszcz, Senior Editor, 630-320-7135, [email protected]

Key concepts

Hose in peristaltic pumps fails from fatigue, regardless of the fluid handled.

Peristaltic pumps maintain metering accuracy up to 1%.

Volumetric output is easily changed by varying pump speed.

Why hose pumps are a preferred method of transfer

– Construction is sealless, glandless, and valveless.

– Interior surface of the tube or hose is the only component in contact with the fluid and the only part of the pump that wears.

– Hose material is much more resistant to abrasive slurries and corrosive chemicals than the metal or PVC components in pumps.

– Simple maintenance requirements reduce downtime and repair costs.

More info

The engineering department at Watson-Marlow/Bredel Pumps is available to answer questions about hose pumps and their application. They can be reached at 800-282-8823.

Hose pump applications

– Slurry transfer, where the particulate matter is particularly abrasive.

– Pumping corrosive chemicals that attack pumps with metal or PVC wetted parts.

– Moving shear-sensitive and high-viscosity fluids.

– Where there is the possibility of the pump running dry.