Lithium-ion batteries, diagnostics and connectivity contribute to solution

Reliable power is essential for profitable well pad operations. Upstream producers have backup power to keep production and storage operations humming while technicians resolve power interruptions. But what happens when backups fail? Two West Texas well pad locations of Anadarko Petroleum, now a part of Occidental Petroleum, illustrate some essential points.

“If backup power goes down, it could take days to get things back up and running, but you never regain that lost production. If production is hundreds of barrels a day and it goes down a few times a month, multiply that by the price of oil. It adds up pretty fast,” said Ron Moore, electrical lead, Occidental Petroleum engineering team.

The original central power supply was 120V or 220V to power pumps and an AC-DC converter uninterrupted power supply (UPS) that provided 24Vdc power to the PLC cabinet and process elements. When something tripped the primary power supply the AC-DC converter was wired to, each primary power supply reduced power to 24Vdc for a backup battery bank of two 12Vdc batteries wired in series.

The power system sat under a shaded structure in an unclassified area. Shade protected the equipment from sun and rain, but the support structure itself was open on three sides. Operating temperatures cycled between 15°F and 130°F, which contributed to failure and inconsistent signals. The charge indicator, for example, might show an hour of charge remaining and then drop to five minutes.

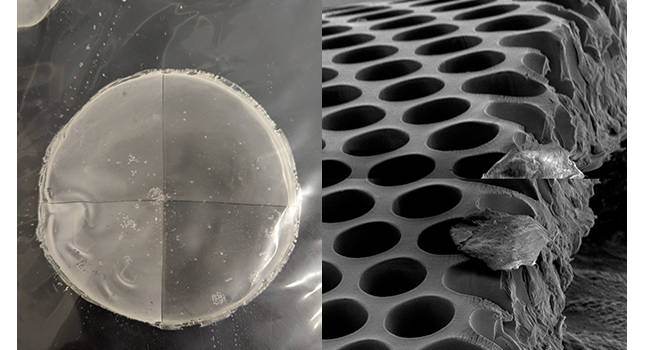

Also contributing to converter failure was dust ingress from caliche, a sedimentary rock, which binds with sand, clay, and silt particles to form something cement-like. “We opened one converter and found a thick, dirty mess. No wonder systems were failing,” said Moore, “regular maintenance was required.”

Perspectives on power

Rather than replace failed units with more of the same, Anadarko engineering wanted a reliable power solution. It began by replacing the lead acid battery backups with lithium-ion technology, for consistent long-term performance. It also wanted more intelligent power, advanced diagnostics and network connectivity, as well as built-in cyber security. The system would be sheltered from the elements.

Locating the upgrade in a non-classified area was considered, but that would require a new rack, additional labor and underground cables. Instead they installed new power supplies in a rack already wired with room to spare. But, in a classified area, new equipment had to be rated for Class 1 Division 2 hazardous locations.

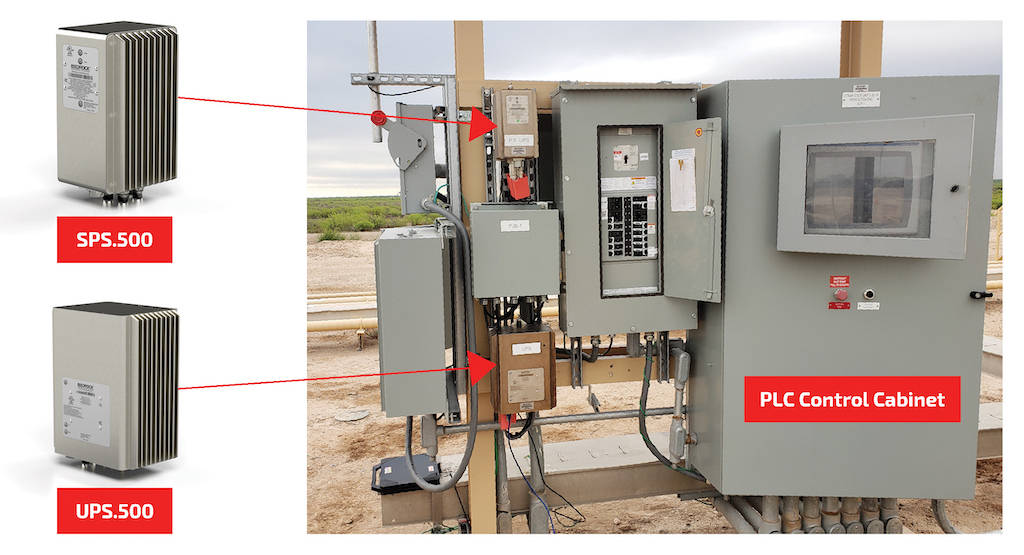

The combination of Bedrock Automation’s Secure Power Supply (SPS.500) and Uninterruptible Power Supply (UPS.500) fit the bill.

The Bedrock SPS.500 SPS. 500 provides single or redundant supply, using 90-264 Vac AC main voltage 50/60 Hz input and is fully certified for use in Class 1, Division 2 locations. Its output of up to 500 watts is software configurable between 21 to 28 volts. Multiple systems can be daisy chained to scale up for higher power requirements. The Bedrock UPS.500 works in tandem with the SPS 500 and provides 24 Vdc at 12AC of backup power for up to 2 hours of consistent backup. An onboard secure microcontroller controls the Li-Ion polymer battery cell-by-cell, augmenting the high density, rapid charging, extreme temperature tolerance and extended life that characterizes Li-Ion technology. The Li-Ion technology also recharges 10 times faster than a conventional lead acid battery system. The UPS.500’s high energy density and compact footprint contributes to Occidental Petroleum’s ability to fit it into available rack space.

In Figure 2, the SPS.500 is mounted above the UPS.500, with the junction box in between. The junction box sends power to the control panel to the right, with the PLCs and relays to the pumps and other field devices. The system’s basic configuration has run flawlessly at both location since 2019.

Next gen reliable power today

The onboard electronics of the SPS.500 primary supply and the UPS.500 backup enable Bedrock Automation’s patented zero trust ICS cyber security. This initiates transparently and instantly upon startup to manage a deep authentication process and protect the reliable power to Occidental’s hardware, firmware, software and communications.

The secure onboard microcontroller comes with 10/100 Mbit Ethernet IPv4 and IPv6 communications and support for Secure Sockets Layer (SSL) Embedded Web Server and embedded IEC 62541 – OPC Unified Architecture Server. Bi-directional communications enable control, diagnostics and status reporting. More than 35 diagnostic variables can be easily monitored, trended, alarmed and historicized via SCADA, forward.

Digital oilfield, digital transformation and full field analytics are among the business challenges Occidental’s Chief of Automation called out in a recent industry presentation. With each Bedrock power unit installed, Occidental Petroleum is equipped to have power components ready to meet those challenges and to keep production flowing.