A recent research summary on PPE and fall protection purchasing behavior and future innovations shows trends, challenges and innovations

PPE insights

- Discover how industry professionals are navigating the evolving landscape of personal protective equipment (PPE) and fall protection, influenced by regulatory changes and technological advancements.

- Uncover the key factors driving purchasing decisions and the future role of smart technologies in enhancing safety measures.

The Plant Engineering Personal Protective Equipment & Fall Protection Report explores current trends, challenges and future innovations in the purchasing behavior and technological advancements of personal protective equipment (PPE) and fall protection.

Purchasing behavior for PPE

Respondents rely on multiple sources to stay informed about new PPE and fall protection products and technologies. The primary resources include search engines (49%), Occupational Safety and Health Administration training (46%), manufacturer/supplier websites (44%) and trade publications (39%).

When assessing the effectiveness of PPE and fall protection gear, respondents prioritize the quality of the brand’s products (81%), previous experience with the brand (64%) and the lifetime value of the product to their organization (55%).

The most effective way for PPE or fall protection brands to reach respondents is through the availability of product information, reviews, datasheets and specifications. Additional effective marketing or educational efforts include product demonstration videos, how-to videos and technical articles.

A significant majority (87%) are open to exploring new brands for their next purchase. Factors influencing this openness include:

-

A brand’s proven reputation in the marketplace (50%).

-

Improved product quality with new features (45%).

-

Demonstrated product lifetime value (42%).

-

Better alignment of the product with facility requirements (42%).

Regulatory changes have impacted budget planning for PPE and fall protection for two-thirds of respondents, while 33% reported no impact and 1% indicated a decrease.

For 68% of respondents, budget allocation for PPE and fall protection is a high priority compared to other safety measures, with 24% deeming it the highest priority.

Current challenges, future innovations in PPE and fall protection

Maintenance and durability of equipment present a moderate challenge for 45% of respondents’ PPE and fall protection programs. For others, it is a minor challenge (30%), not a challenge (13%) or a significant challenge (12%).

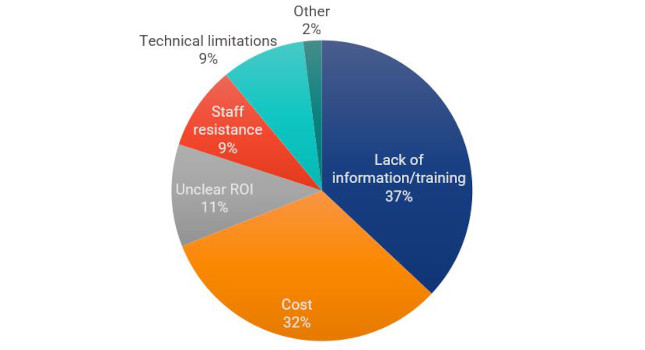

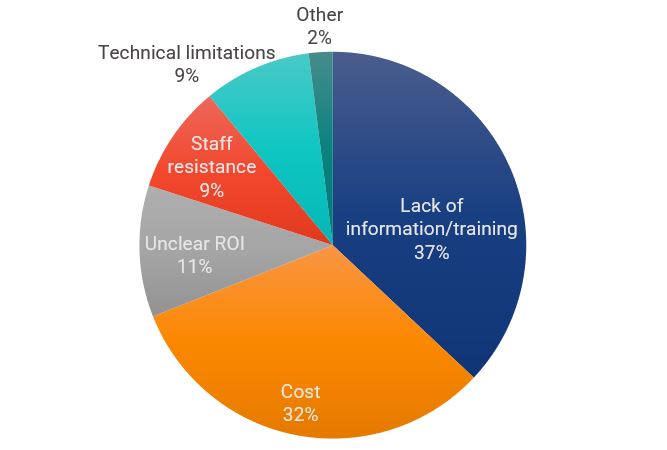

The two major barriers to adopting new technologies in PPE and fall protection are a lack of information/training (37%) and cost (32%).

PPE and fall protection strategies are primarily influenced by the type of work they are needed for, regulatory requirements and the safety history/reputation of the equipment.

Looking forward, 36% of respondents believe augmented reality will play an important role in future PPE and fall protection training programs, with 20% considering it critical.

More than half (55%) of respondents anticipate the use of smart technologies to enhance training and simulations for PPE and fall protection in the next five years. Other anticipated useful smart technologies include automated alerts and notifications (51%), continuous innovation (46%) and real-time monitoring (45%).

To download the complete Plant Engineering Personal Protective Equipment & Fall Protection Report, register for the full study.