FLIR, a Teledyne Technologies company, introduced the FLIR Si1-LD, an industrial acoustic imaging camera designed for cost-conscious condition monitoring applications. The FLIR Si1-LD features enhanced detection and quantification capabilities compared to the existing FLIR Si124-LD Plus, with an expanded upper frequency range.

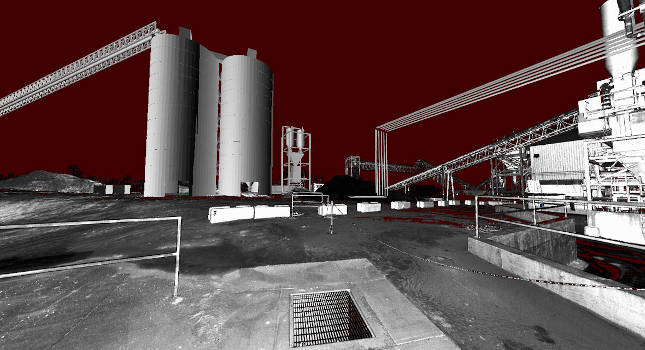

Compressed air systems typically lose 25–30% of their air to leaks, leading to increased energy costs, unexpected production disruptions, reduced compressor lifespan, and potentially requiring additional compressor capacity, which can result in higher maintenance costs.

Using ultrasonic technology, the new FLIR Si1-LD detects leaks with improved imaging accuracy at a competitive price. It includes key features such as:

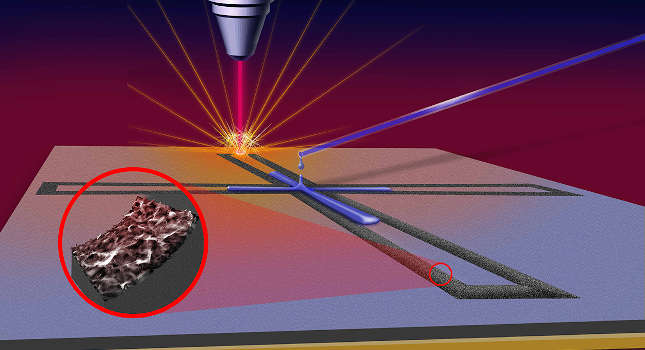

- An array of 96 microphones (2–100 kHz) facilitates the automatic detection, location, and measurement of compressed air and vacuum leaks from a safe distance of up to 130 m. Support comes from a 12 MP color camera with 8× digital zoom and LED lamp, facilitating the easy capture of visual details.

- Bandpass filtering allows inspectors to filter out unwanted ultrasound noise without manual tuning. For complex leak detection tasks that require manual adjustments, the bandpass filter enables the inspector to fine-tune the frequency range and display the source of interest when needed.

- The FLIR Si1-LD ultrasonic imager is designed for one-handed use and portability. Its AI-powered analysis supports usability with a short learning curve, making it suited for large-scale facility inspections.

- The touch-screen interface displays detailed images to assist in issue identification and provides real-time quantification of leak volume and annual cost. Users can use this data to prioritize repairs, and it can also support sustainability reports by tracking energy reduction efforts.

- Wireless data transfer supports reporting and analytics using either the online FLIR Acoustic Viewer or offline FLIR Thermal Studio. It enables data backup, team collaboration, and supports Over-The-Air (OTA) firmware updates. The software allows users to create reports with pre-built or customizable templates.

“Many manufacturing and process plants are seeing their energy bills creep up through leaky compressed air systems, increasing OPEX [operational expenditure] and eroding margins,” said Darrell Taylor, global acoustic business development manager at FLIR. “If you want to find leaks quickly and easily with minimal technician training, our new Si1-LD industrial acoustic imaging camera provides a fast and precise solution that supports sustainable manufacturing. As well as reduced energy consumption, the new device helps you save on maintenance, repair, operation, and capital/OPEX costs —all while enhancing worker safety. With its minimum detected leak rate [MDLR] of 0.01 L/min at 2.5 m, our Si1-LD offers the market’s best combination of performance and ease-of-use in its price point.”

The new acoustic imaging camera comes with two batteries, additional battery cover, battery charger, camera neck strap, hard case, USB memory stick, access to free versions of online & offline acoustic analysis and reporting software, and two-year warranty. A new accessory is the data transfer cable. This handy cable allows users to connect directly from the camera to a PC/laptop, supporting easy file access at organizations that forbid the use of WiFi and USB drives. Users can upload their acoustic images into FLIR Thermal Studio software or the FLIR Acoustic Viewer.

Two versions of the Si1-LD are available, with and without WiFi. All other features are the same.

For more information, please visit teledyneflir.com.