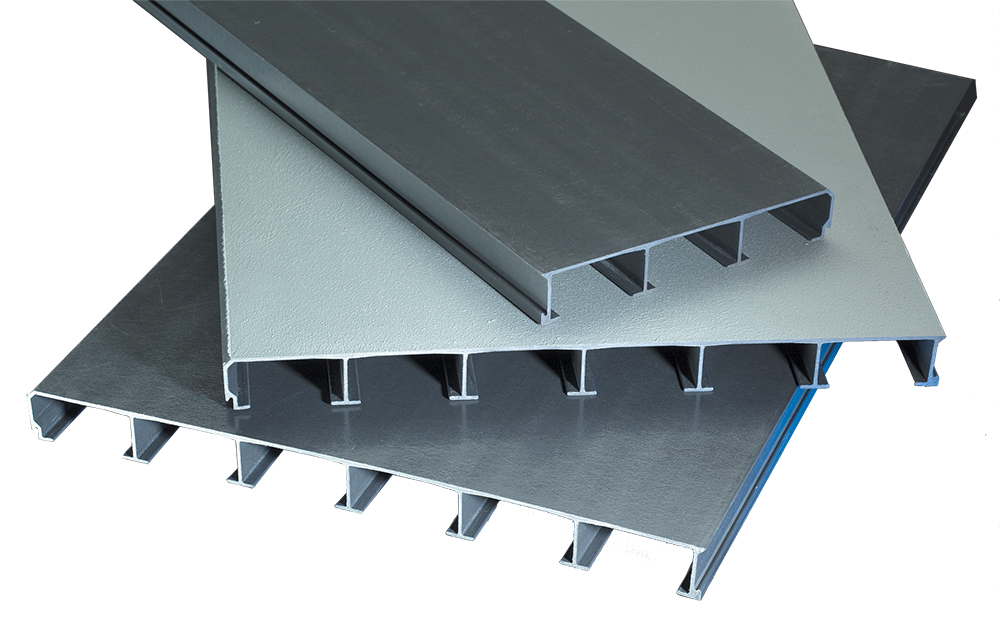

First used in 2000, SAFPLANK is a high strength system of fiberglass planks designed to interlock to form a continuous solid surface. SAFPLANK is intended to replace wood, aluminum, or steel planks in environments where corrosion or rotting creates costly maintenance problems or unsafe conditions. SAFPLANK is available in 2″ deep panels measuring 12″ or 24″ wide. A slotted version is also available to offer flexibility in design. Stock panels are available in 20′ and 24′ lengths. Other lengths are available upon request. SAFPLANK may be ordered with a grit surface or with a smooth surface for non-pedestrian applications.

SAFPLANK is designed to be used for flooring and covers. Typical applications include:

-

Temporary Flooring

-

Odor Control Covers

-

Windwalls

-

Dock Surfacing

-

Roofing Walkways

-

Cellular Wall Panels

-

Concrete Forming Systems