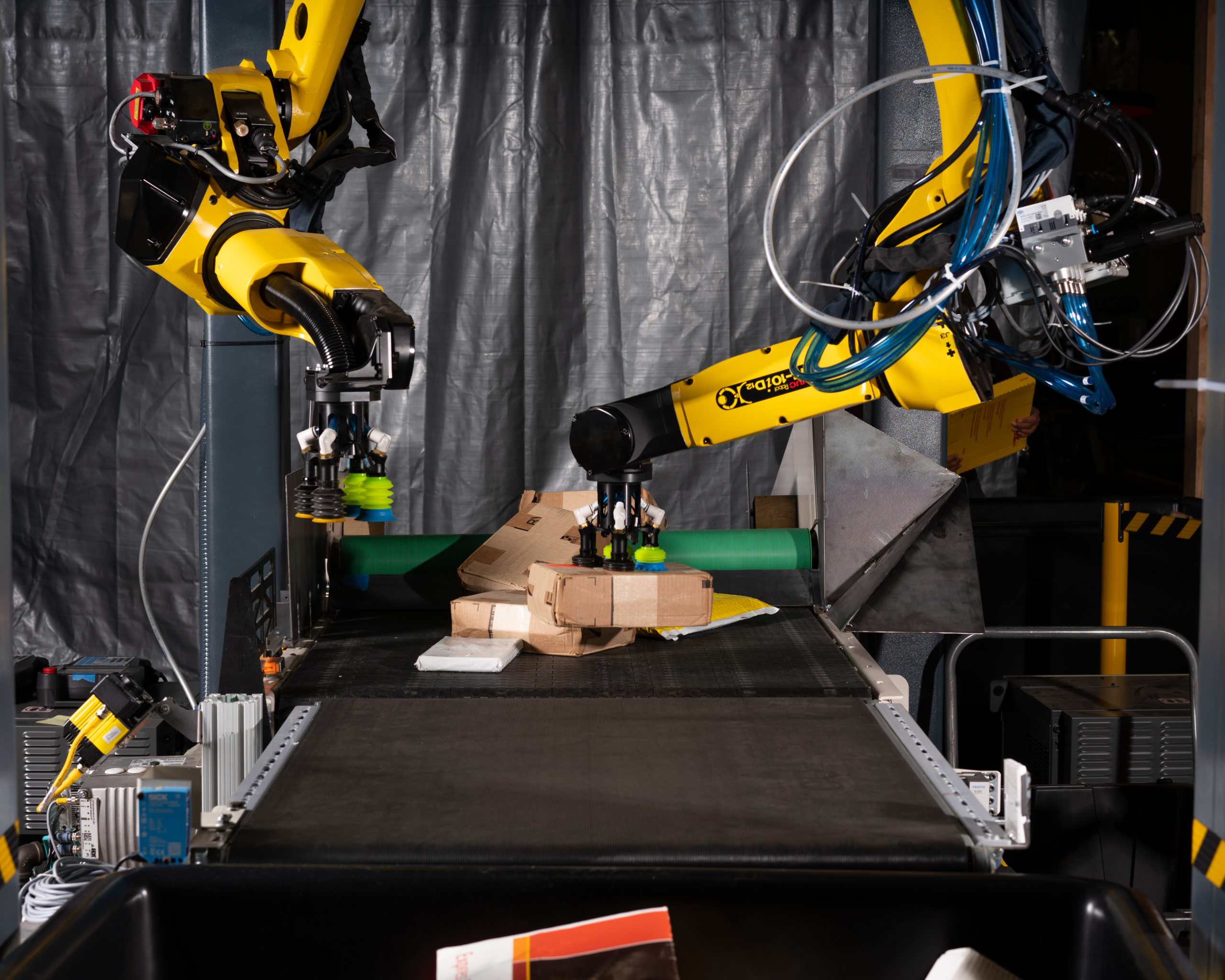

Capable of processing up to 2,800 parcels per hour at its peak with a typical range of 1,900-2,500 parcels per hour, this space-efficient solution combines advanced robotic technologies to identify and pick from bulk infeed, and place singulated packages in a proper orientation with speed, accuracy and efficiency. The picking process is powered by vision software, machine learning algorithms and state-of-the-art computer vision, allowing for seamless fusion of 2D and 3D data with low latency times. The robots’ gripping system uses vacuum-based end effectors to handle a variety of common packaging materials and types, including corrugate cases, polybags, flats and envelopes. The solution handles items as small as 3” x 3” x flat and as light as 0.1 ounces, as well as items as large as 20” x 20” x 20” and weighing 20 pounds.

Once each item is picked, a vision confirmation system verifies each parcel is in the proper location for downstream processes, and that it’s only one single package. When necessary, the system will learn from each pick attempt and automatically retry picks before allowing the parcel to proceed to the sync and merge zone. Exception cases are processed by the solution’s automatic reject function without interrupting the continuous singulation. Operations can also add additional functionality to the solution through optional modules, such as an in-line scale and scan tunnel. Integration with warehouse software allows for remote monitoring and control.