Webcast presenter Lanny Floyd provides an overview and history lesson on arc flash and electrical safety and some of the standards critical for engineers.

Arc flash and electrical safety insights

- Historical Development: Arc flash safety has evolved since the 1960s, starting with pioneers like Bill Jordan and Ralph Lee, who established early safety programs and analytical techniques, setting the foundation for current standards.

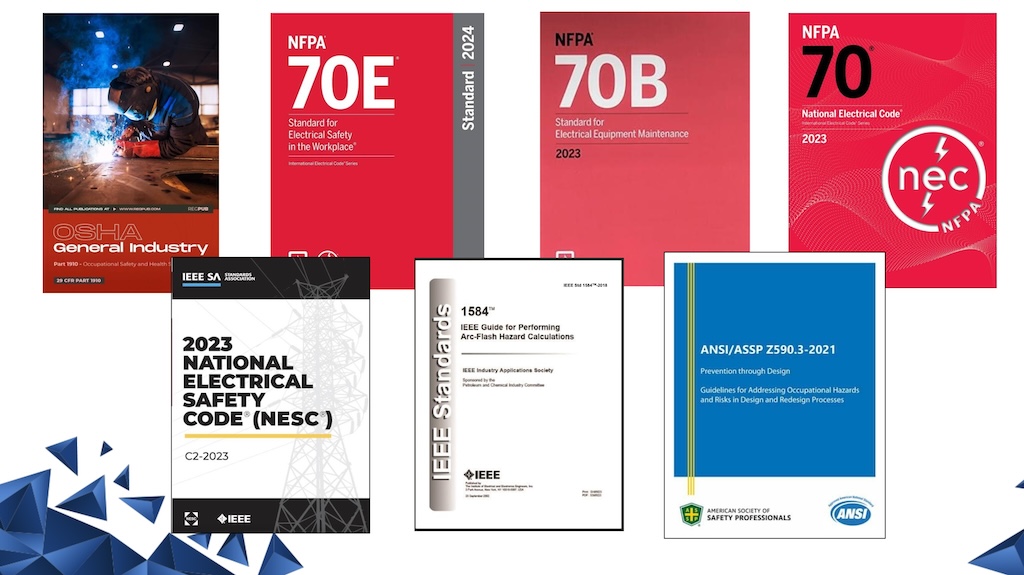

- Standards and Codes: Key standards like OSHA 1910 Subpart S, NFPA 70E, NFPA 70B, and IEEE 1584 provide comprehensive guidelines for safe practices, maintenance, and arc flash hazard analysis, essential for preventing accidents in manufacturing facilities.

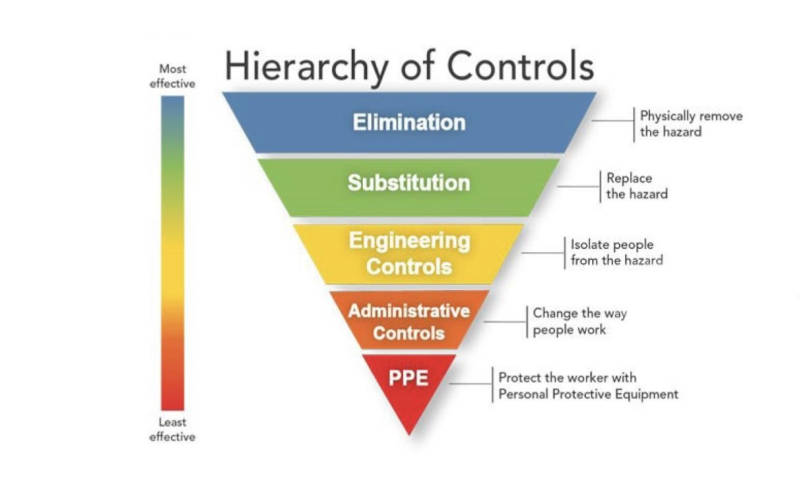

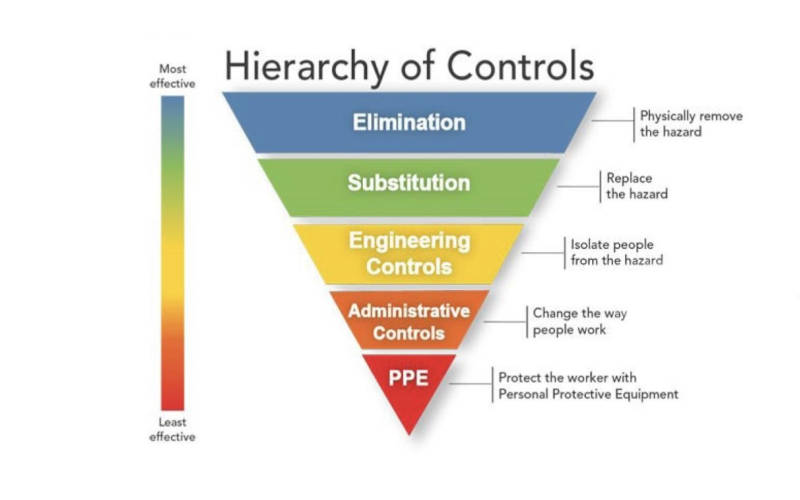

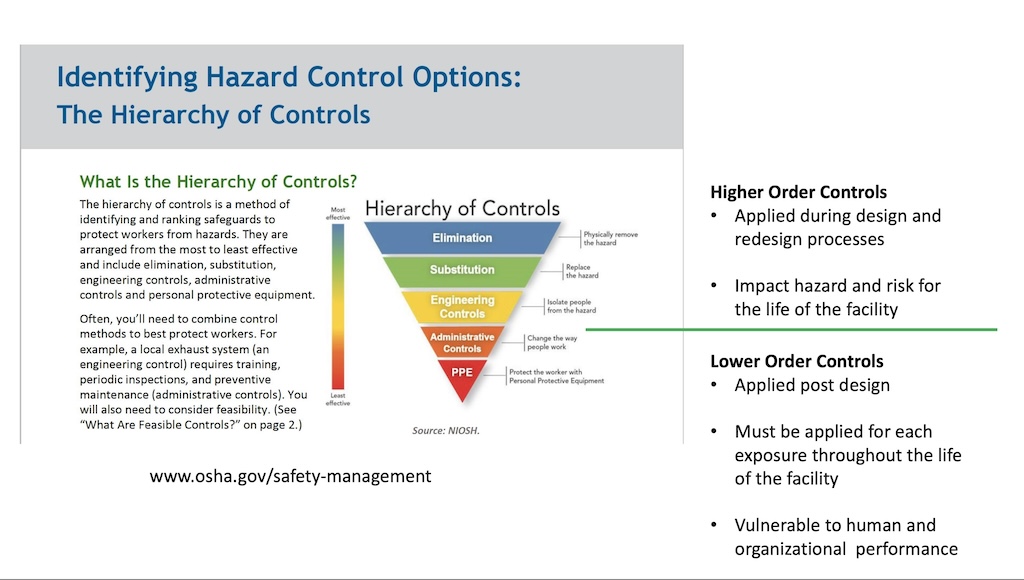

- Hierarchy of Controls: Effective arc flash mitigation involves a hierarchy of controls, emphasizing elimination, substitution, and engineering controls over PPE. High-order controls, implemented during design, have a lasting impact on reducing risks throughout a facility’s lifecycle.

Arc flash and electrical safety are critical aspects in a manufacturing facility. Knowing and understanding the fundamentals often mean the difference between life and death. Companies and workers need to stay on top of the electrical codes so they can better protect themselves from a potential accident.

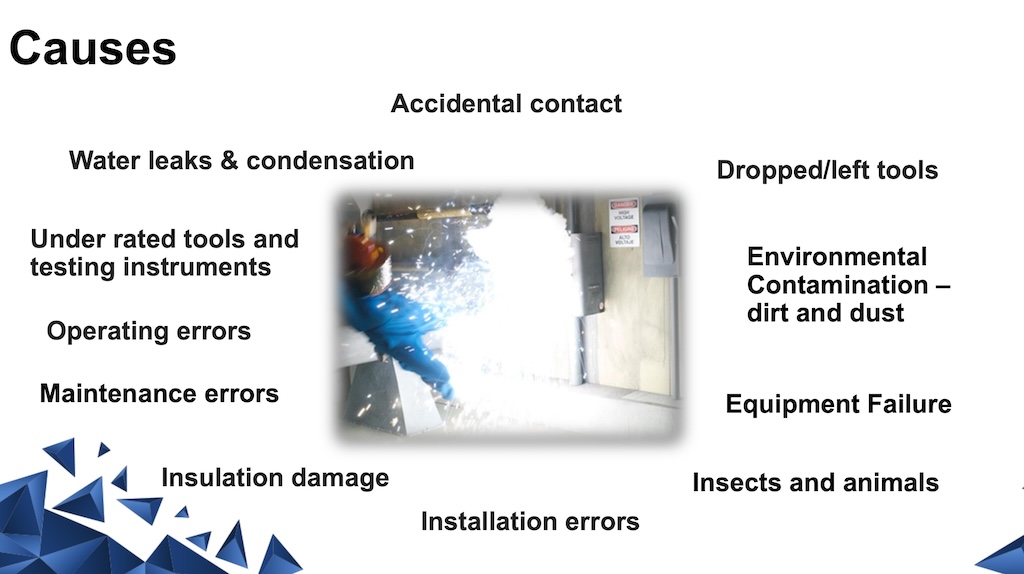

In a manufacturing facility, an arc flash is a dangerous release of energy caused by an electrical fault that occurs in equipment such as circuit breakers, switchgear and other electrical components. This can happen during normal operation of the equipment, as well as during maintenance or repair. The intense heat and bright light generated by an arc flash can cause severe burns and other injuries to workers, as well as damage to equipment and facilities.

An arc flash event can be triggered by several factors such as human error, equipment failure, corrosion, dust, moisture and others. Such an event can happen in several ways, such as a short circuit, a ground fault, a loose connection or a failure of insulation.

Lanny Floyd, partner and principal consultant, Electrical Safety Group and Bibek Karki, power systems electrical engineer for IPS, discuss arc flash and electrical safety and what engineers need to know from the June 20, 2024, webcast: “Electrical safety: Know the fundamentals of arc flash mitigation.” This has been edited for clarity.

Lanny Floyd: The first thing I would like to do is give a little history about arc flash mitigation and how we’re doing it today. Many people I talk with think that the arc flash requirements are relatively new. They may be relatively new in standards and regulations, although they’ve been there for 15 years. I would like to go back to the late 1960s and in 1969 we see a photograph here of a gentleman by the name of Bill Jordan. In the 1960s, he led the design and implementation of the first arc flash safety program and was at the largest industrial complex in North America. This photograph was actually taken in 1992 when we were celebrating bill’s accomplishment that he brought to electrical safety decades earlier.

In 1981, Ralph Lee, who was an extraordinary electrical engineer focused on electrical safety, published this paper, The Other Electrical Hazard: Electric Arc Blast Burns, in which he outlined a technique to estimate the thermal energy exposure and arc blast events. And he was using the tools of power system analysis that were available at that time. I’d also like to point out that Bill and Ralph knew each other and they collaborated in some of their work together. In 1980, Bill Jordan’s electrical safety program was featured in an article in the April of 1980 issue of Chemical Engineering Magazine. You can see the photograph there in the top center. That was his arc flash suit that he had actually adapted from steel making that was used in arc blast furnace operations back in the 1960s. So again, my point on these two slides is that the work on arc flash has been going on for a long time.

In the 1980s, two people by the name of John Gallagher and Bruce McClung started collecting industry best practices for electrical safety and they published their collection in a book title Electrical Hot Work Safety Program. Here on the left-hand side, you can see a slide of John there on the left and Bruce on the right giving a tutorial where they’re teaching people in industry, end users as well as manufacturers about what they’ve gathered in their search for electrical safety best practices. I bring this up because these early pioneers and there were others as well, set the stage for what we now have as code standards and regulations that are useful to us in helping mitigate prevent electrical arc flash events and protect people from arc flash events that they do occur.

We have across the top there from the left we have the OSHA Standards, 1910 Subpart S. We have the NFPA 70E, which provides safe work practices that was most recently updated for 2024. We have NFPA 70B, which is something unique about 70B is that this issue, the 2023 issue, the document was revised from being a recommended practice to being is now titled The Standard for Electrical Equipment Maintenance. This particular document provides the most comprehensive guidance for electrical equipment maintenance, including the equipment that’s critical to mitigating arc flash as well as the equipment that can have failures or mishaps in it that can lead to arc flash events. We have NFPA 70, the National Electrical Code, again a 2023 revision. It’s had requirements for labeling of art flash hazards since the 2000 edition. So we have those at the top. At the bottom across on the left is the National Electrical Safety Code that was revised in 2023.

The National Electrical Safety Code focuses on electric utility operations and it provides currently, and it has for several cycles now, for provided guidance for arc flash mitigation and protection for exposures in overhead power lines. And that is uniquely different than most exposures in industrial facilities where you have arc events that incurs in any enclosures or metal boxes so the forces are more concentrated out toward the workers at risk. We have in the middle, at the bottom is the IEEE Standard 1584. This was first published in 2002. We have the more recent edition just a few years ago. This is the standard providing guidance on performing arc flash hazard analysis.

To the best of my knowledge, all of the software programs available today to do power system analysis and arc flash hazard calculations are based on 1584. The standard on the lower right is not an electrical safety standard, but it is very important when we talk about mitigation or prevention of arc flash events. And this is the ASSE/ANSI Standard Z590.3 last revised in 2021. It provides guidance on applying prevention through design principles to whether it’s a new project, new facility, a renovation, a retrofit, a tool design. And again, it’s not about electrical safety, it’s about the process of applying prevention through design.

I’m going to go back and emphasize something. The OSHA Standard 1910 Subpart S and NFPA 70E are the two, is the regulation and standard that provides the safe work practices. That’s important. The other standards have to do with maintenance and labeling and the analysis. I think it’s really important to recognize that the big killer and electrical safety is electrocution, the electric shock. Almost all the fatalities that occur in the United States in the workplace with contact with electrical energy is related to the passage of current to a person’s body. That’s electric shock. That’s the hazard that’s been around that we’ve known about since the beginning.

The arc flash exposures causes a lot of injuries and the injuries are horrible. They can be horrible, they can be permanently disabling, permanently disfiguring, and can result in medical needs for the remaining life of the individual that was burned. And that can be a very long time if the person is burned when they’re young. But I wanted to emphasize that the big killer is electric shock. You can go to the National Fire Protection Association (NFPA). They provide an analysis of electrical statistics, injury and fatality statistics. And also the easiest place is the Electrical Safety Foundation. If you look at the tab at the top for workplace safety, you can get the workplace safety injury and fatality statistics there also. Again, you can do all you want to protect arc flash injuries, it’s likely not going to address the big killer in electrical safety.

It’s not to say that arc flash doesn’t cause a lot of injuries, I’ve just said that. It’s very important. It’s two distinct hazards and we have to address both of them. Today we’re talking about arc flash. This illustration is from OSHA. If you can go to the URL there that’s shown on the slide and get a lot more information than what I’m showing here on on the screen. But one of the resources on that website is this document titled Identifying Hazard Control Options: Applying the Hierarchy of Controls. And you can see the illustration here from elimination, substitution, engineering controls, administrative controls and PPE and it’s going from the most effective to the least effective. We put a lot of emphasis on PPE, but we need to recognize that there are significant limitations. PPE will not prevent an incident. The PPE will not prevent an incident. It will help reduce the severity of injury if an incident should occur.

Again, that’s why over on the right-hand side, we see what’s called the higher order controls. They’re applied doing design and redesign processes and once they’re put in place in the design of the facility or the production site, they impact the hazard and risk for the entire life of the facility. That’s why they’re so important. The lower order controls below the green line are applied after the facility is built, it’s already been designed. We’ve done everything we can at that point to reduce risk. So now we’ve got to address the remaining risk with these lower order controls. They must be applied for each and every exposure throughout the life of the facility. That can be thousands of exposures and you’ve got to do something each time to mitigate the exposure and the lower order controls are also vulnerable to human and organizational performance. People need to know what to do, do it every time and do it right. All of these controls are extremely important.