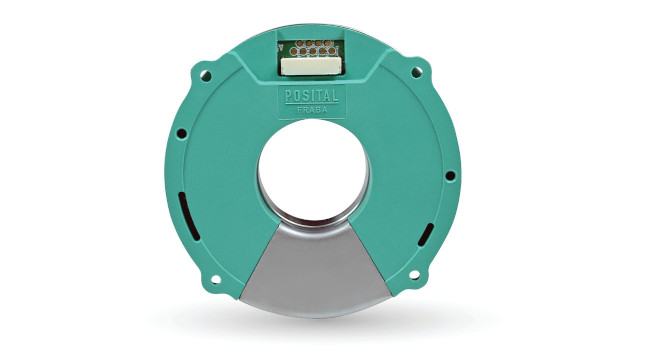

The intelligent closed-loop direct-drive smart gripper is designed to deliver precise gripping capabilities with a powerful programming interface, as well as easy integration with most commercially available robots.

Smart Gripper 2.1 intelligent closed-loop direct-drive smart gripper is designed to deliver precise gripping capabilities with a powerful programming interface, as well as easy integration with most commercially available robots. The gripper features accurate robotic finger positioning, adjustable grip force, easy installation and requires no external controller. The gripper uses a universal operating platform and closed-loop encoder-based robotic finger positioning. Its fingers can be designed by the company or the user. The gripper is operated using discrete 24 Vdc signals for use with any robot controller. The user pre-programs motions into its non-volatile memory for later recall triggered by the robot controller’s discrete output lines. Up to 32 programs can be selected using the gripper’s five discrete input lines. The gripper can provide status back to the robot controller using the gripper’s three discrete output lines.

Applied Robotics Inc.