Short circuit current analysis is an essential part of the design and safe operation of electrical systems and obtaining the right equipment is a crucial step.

Short circuit current analysis is an essential part of the design and safe operation of electrical systems. Many companies have put together arc flash studies and completed labeling to increase electrical safety, but did you know obtaining equipment properly rated for a short circuit is just as important as knowing about and mitigating arc flash dangers?

It’s in the details

As an electrical concept, a short circuit is when an electrical current flows down an unintended path with very low impedance. This results in an extremely high current flowing through the circuit. The available short circuit calculated at a point in the system represents the maximum current flow the system can deliver to that point. The short circuit rating of an electrical component is then designed and tested for the maximum current flow that the device can safely withstand.

The National Electric Code says that you must label service equipment with the available short circuit. Industrial control panels shall not be installed where the available short circuit current exceeds the listed rating. Systems can act unpredictably when the available short circuit energy exceeds the listed rating of the equipment.

What could go wrong? The contacts inside a circuit breaker could fuse and not allow the breaker to clear the fault. Mechanical stresses on the busbars inside a switchboard could cause them to break their supports and trigger an arc flash event. Equipment in a control panel could “burn up” and no longer function properly. In each of these cases, it can endanger the health of the equipment, safety of personnel, and ability of the plant to operate normally.

Keeping your plant safe

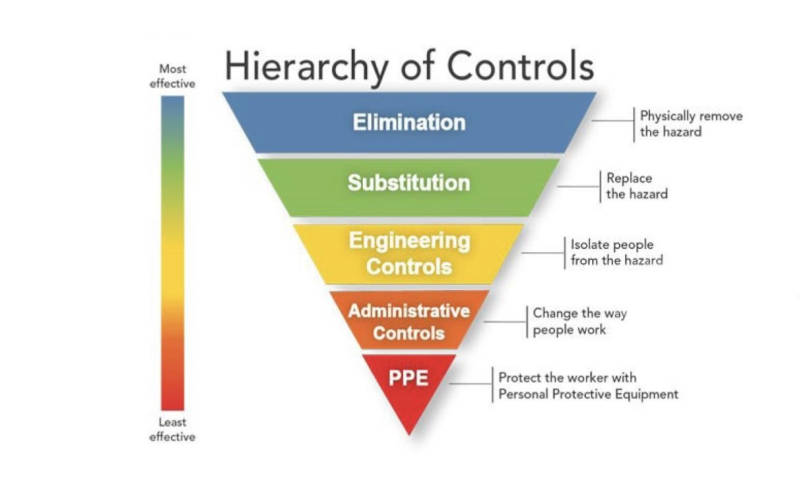

To avoid these situations, consider these best practices when making modifications to the electrical system:

- Replacement parts should be identical to the original not to alter the short circuit rating of the repaired equipment.

- Complete a rudimentary short circuit analysis before ordering new equipment and work with the manufacturer to achieve a rating sufficient for the installation.

- Adjust the design of the electrical system to reduce the available short circuit current to align with the ratings of the equipment.

As an example, think about a facility considering an air compressor upgrade. The short circuit analysis would return the following data points:

- The 2500 kVA transformer can deliver approximately 53,000 A of short circuit current.

- The 3000 A switchboard is chosen to be rated at 65 kA to align with the available system current.

- The 600 A MDP is calculated to have approximately 37,000 A of short circuit current available, so the panel is purchased with a 42 kA rating to align with the available system current.

- The calculated available short circuit current at the 200 A air compressor is approximately 23,000 A, so the manufacturer supplies a 30 kA rated air compressor to align with the available system current instead of the typical 5 kA rating for that machine.

– This originally appeared on Interstates’ website. Interstates is a CFE Media and Technology content partner.