Eventually, boiler replacement is inevitable

Regardless of how robust the construction, boilers don’t last forever. Advances in technology result in more efficient designs and simplicity of operation. The BASF facility in Durham, N.C. reached the point with its boiler plant where replacement was necessary.

Existing boiler plant operation

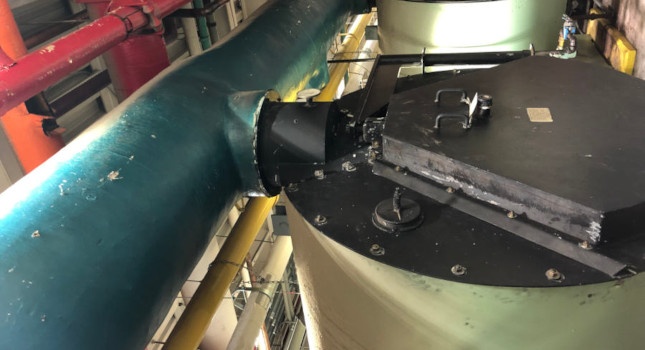

The two existing firetube boilers at the BASF facility in Durham, N.C. were manufactured by York Shipley Inc. in 1981 with a capacity of 300 boiler horsepower each. The boilers operated admirably during their 40 years of service (see Figure 1). However, with age, the boilers started to require increasing maintenance. With renovations and improvements downstream came a large reduction in steam output needs. The boilers, being limited on steam output turndown, began short cycling in the summer and winter. The on/off operation resulted in more stress on the boiler and burner equipment and a reduction in overall energy efficiency of the system.

The existing spray deaerator was not meeting ASME dissolved-oxygen requirements of 7 ppb. This resulted in an increase in non-condensable gases to the boiler and eventually into the steam system. With these elevated non-condensable gases in the system, higher corrosion rates of internal piping and infrastructure did occur. All other associated equipment such as blowdown tank, chemical feed system, makeup water meters and steam flow meters were deemed to be older technologies and needed to be updated to the latest technologies.

It was time to upgrade the boiler plant. The goals for upgrading the boiler plant system were to achieve the highest degree of safety, system optimization, high reliability and an energy efficiency with today’s technologies. Along with these goals was to also create a work environment that is highly desirable to work in for plant operations and plant personnel. With the boiler upgrade, other aspects of the system were reviewed and upgraded such as the associated support equipment, which included the deaerator, blowdown and chemical systems.

Engineering project scope

Inveno Engineering, LLC senior steam team field engineers and the Swagelok local support team were assigned engineering and design for the new boiler project. The project, which began January 2019, consisted of engineering, design, full AutoCAD prints, equipment specifications, request for proposals (RFPs) and procurement recommendations. The engineering scope was to encompass the boiler selection process, boiler plant layout, code validation, specifications, vendor interviews, installation, startup and validation testing. Inveno engineers implemented the steam system team concept, which included onsite engineers, onsite AutoCAD team, offsite technical personnel, offsite support engineering, technical writers and support staff. The Inveno team worked with the BASF team to ensure a successful project.

The steam system engineering team goals were to accomplish:

- Safety

- Reliability

- Plant optimization

- Energy efficiency

- High turn down to meet plant steam requirements

- Latest technologies in boiler control and management

- Proper deaerator operation with newest control system

- Chemical treatment.

Another part of the project was to develop a detailed steam system balance, ensuring that the new boilers will meet and exceed the steam system requirements.

An essential part of the project is to ensure all codes are followed to ensure a safe operation for everyone involved. The following codes were adhered to during the entire project, Boiler ASME, B31.9, B31.1 ASME pressure vessels, B16.1, etc.

New boilers: Firetube versus watertube

One of the first steps in deciding on new boilers is to determine the operational design of the boiler. Firetube design and watertube design were the two boiler designs considered. All boilers have their positive and negative features. The Inveno Engineering steam team and BASF reviewed all aspects of operation including their loads and run conditions and decided to proceed with a watertube design boiler.

The firetube boiler design was eliminated due to several considerations. First is the installation consideration for a firetube boiler that requires additional space for boiler tube replacement if required after years of operation. The other negative consideration is the thermal losses off the exterior casing of the firetube boiler, specifically, the back wall area. The firetube boiler back wall would have high elevated temperatures of more than 300°F thus an energy loss in excess of $25,000 a year. Safety concerns for plant personnel with high surface temperatures and OSHA requirements for plant personnel protection for areas of greater than 140°F. Insulating the firetube back wall presented several operational issues such as having to remove the insulation for annual boiler inspections.

The watertube boiler presented a much smaller footprint and ease of accessing the boiler internals maintenance. Watertube boilers provide better compensation for expansion and contraction thus providing a longer operational life expectancy. The combination of the boiler and a burner design allowing for 10:1 turndown with the addition of the latest control technology provided the perfect combination for this specific application.

Control systems

The boiler control system design was selected to be a parallel positioning control with oxygen trim because it was determined to be the best control scheme for the boilers. Parallel positioning systems offer key design benefits over the other control schemes for this size of boiler operation. One actuator positions the fuel control valves, while a second actuator positions the air control damper. Each combustion actuator is equipped with a position re-transmitter for cross limiting purposes to ensure proper fuel/air mixing. The parallel positing system allows proper tuning of the fuel/air ratio for each firing rate demand, typically at each 10% of the firing curve (see Figure 2).

Oxygen trim system adjusts for any factors that may affect the fuel/air ratio curve and adjusts accordingly to keep the combustion at peak performance.

Advantages for this control scheme includes:

- Allows electronic characterization of fuel/air ratio

- Boiler will have variable speed drives, which mates to this control scheme

- Provides large turndown

- Oxygen trim is easily accomplished.

The control system and the burner management system were to be accomplished by programmable logic controllers (PLCs), which also provide relevant data and operational parameters for the plant personnel. The boilers, DA tank and flowmeter data were set up to connect to the site’s building automation system (BAS), notifying personnel of key alarms and allowing for energy tracking of consumed resources (e.g., natural gas, makeup water, steam output).

Fuel/air ratio: Combustion process

The combustion fuel/air ratio curves are derived from a combustion testing process and is important in the overall boiler efficiency. Lower oxygen levels are in direct relationship to the quantity of excess air required for the combustion process. To achieve complete combustion, a portion of combustion air must be available for the combustion process that exceeds the stoichiometric amount needed to complete the combustion process. The ratio of the excess combustion air to the theoretical amount of air required is called “excess air.”

Due to the burner characteristics, the excess air levels are curved from low fire, which has higher excess air levels (oxygen levels) on a curve up to high fire that has lower excess air levels.

Unfortunately, if more excess air is added to the combustion process, it results in lower combustion efficiency. The combustion process/burner is taking ambient air for the oxygen needed in the combustion process, but it has to heat up all the other gases in the ambient air such as the large quantity of nitrogen. All combustion air will be increased to temperatures above 2,600°F and higher, which is the flame temperature.

The new burner technologies allow the burner to operate at lower or reduced excess air in the combustion process. Another benefit is the flue gas exit volume is reduced. Lower excess air levels reduce the flue gas temperature and gas velocities. The flue gas velocity reduction allows the gas to spend more time in the boiler where the heat energy can be absorbed. The fuel/air curves for each of the boilers is shown in Figures 3 and 4, which indicate the curves with the older boilers versus the new boilers.

The fuel/air curves for each boiler indicate the significant reduction in excess air levels thus improving boiler efficiency (see “Old versus new: Energy efficiency gains”).

The economics are attractive for keeping a boiler operating at peak performance with respect to the optimum fuel-air ratio curve. BASF can monitor the fuel ratios and has Cleaver-Brooks local technical support team check the operation on a periodic bases to ensure the optimal performance.

Deaerator (spray versus tray design)

The new deaerator design was required to provide a feedwater dissolved oxygen content of no greater than seven ppb and operate at steam pressure of 8 psig with a 20-minute feedwater storage time for the boiler operation (see Figure 5). Reviewing the two deaerator design choices, the spray type and tray type design, both deaerator types can provide the performance standard dictated by the engineering RFPs. However, due to height considerations of the existing boiler plant, it was decided to proceed with a spray-type deaerator that had a lower height requirement and maintained the required net positive suction head (NPSH) for the boiler feed pumps. The control system for the deaerator was another area where the plant needed to have control of the steam pressure, feed pumps and monitor the critical points in the system.

Insulation

Keeping with the proactive insulation management program was critical to overall boiler plant system to maintain a high steam system thermal cycle efficiency. Because boiler components (deaerator, blowdown tank, etc.) operate above 212°F (100°C) temperature can have negative effects on uninsulated control components and energy losses. This is unacceptable in today’s industrial boiler operations.

What items in a boiler plant and system need to be insulated? The simple answer is everything. Insulating the steam lines is not sufficient in today’s boiler plant operation. Therefore, the deaerator, steam line, condensate lines, blowdown tank and other boiler plant-related components were insulated. All insulation was metal jacketed to ensure the long-lasting energy and safety effects of the insulation.

Plant layout

The philosophy of BASF and the Inveno steam team demanded the boiler plant be free of components not related to the boiler operation. The boiler plant is not a storage area; it is an area where the combustion process is occurring with a very combustible fuel. The other factors are to have a clean, well-organized and well-lit environment for the boiler plant personnel that provides an excellent work environment and work habits (see Figure 6). With this type of environment, the boiler plant will stay in this condition for the life of the boiler and plant personnel will take pride in their plant.

Chemical systems

A key factor in a boiler chemical program for a steam boiler operation is to be able to conduct daily steam/boiler samples for testing. The chemical program is a major factor to have a reliable and long operational life of the boiler and steam system. In any boiler plant sampling system, a central steam sampling location is a must for any boiler chemistry monitoring program. The next key factor for the steam sampling system was to ensure that all components are meeting the code requirements and designed for long reliable operation. Inveno steam team discovered that more than 37% of existing steam/boiler sampling systems had code violations.

Swagelok was able to provide a custom solution with a central sampling system that provides all aspects for code requirements and personnel safety. The central steam/boiler sampling system allows plant personnel to take the required samples with a safe and reliable operation. The new sample cooler used Swagelok tube fittings coming from the boilers and DA tank. The high-quality airtight fittings provided a robust test result of the dissolved oxygen testing for the deaerator. Testing the deaerator operation to 7 ppb or lower is a low dissolved oxygen level and the plant could not afford to question the testing results that could be influenced from air leakage from low quality tube fittings. The plant reduced the chemicals consumption from three different chemicals down to one chemical for the overall boiler operation. BASF implemented a new “Ultramine” program. This simplified the maintenance of the chemical program, which reduced chemical storage and handling as well as chemical pump failures.

Final manufacturer selection

One of the key factors in the final manufacturer final selection was the engineering support the manufacturer could bring to the project. Another key factor was the technical local service support for all the boiler plant components. Any boiler plant operation needs to have the required technical support and service to ensure an energy efficient and reliable operation.

Cleaver Brooks was selected to the be manufacturer for all the boiler plant equipment. The company’s equipment met all of BASF’s extensive requirements and it has a highly reputable local service team that can aid in the long-term upkeep of the new equipment.

Return on investment

Although the project was not undertaken with energy savings in mind, the return on investment (ROI) from energy savings alone is estimated to be around $30,000. Saving energy is a noble goal. However, there were other more pressing considerations. The existing equipment was at the end of its operational life. BASF wanted to acquire the newest technology in boiler operation, which it did. The deaerator was not performing. The boilers were at high cycle rates in summer operation. BASF now achieves a 10:1 boiler turndown ratio. The new boilers are not attended; the new system allows for remote monitoring. The boiler room layout is improved for more efficient operation and maintenance (see Figure 7).

Kelly Paffel is the technical manager at Inveno Engineering, LLC. He is a global expert on steam systems and boiler plant operations with more than 40 years of experience. Paffel is known for his online publication “Steam System Best Practices,” a resource used by plants and engineers internationally to ensure proper operation of steam and condensate systems.

Jeff Coger is facilities engineer at BASF Agriculture Solutions. He received his undergraduate mechanical engineering degree from Kettering University. His background includes seven years in automotive manufacturing engineering and as many years as a facilities engineer. He has a passion for solving problems but solving them in a way that prioritizes quality, reliability and maintainability. Coger firmly believes in approaching projects with the mindset, as quoted by Benjamin Franklin, “The bitterness of poor quality remains long after the sweetness of low price is forgotten.”

Key project personnel involved in the project

The key project personnel involved in the BASF boiler upgrade project were:

- Jeff Coger; facilities engineer, BASF Agriculture Solutions, Seeds & Traits; Durham, N.C.

- Jordon Grigston, local technical support, Swagelok

- Kelly Paffel; technical manager/project team leader; Inveno Engineering, LLC; Naples, Fla.

- Graham Thorsteinson; senior field engineer; Inveno Engineering, LLC; Naples, Fla.

Energy efficiency gains

Energy efficiency gains as the result of installing new boilers and deaerator include:

- High boiler efficiencies

- 75.2% (older boilers) versus 83.9% (new boilers)

- Lower excess air levels in fuel/air ratio

- Energy losses from an on/off operation (older boilers) versus continuous operation with the new boilers (higher turndown)

- Lower thermal losses with the new boilers

- No high temperatures from any side of the new boilers compared to the older boilers high back wall temperatures

- Less boiler outside surface area than the older boilers, thus reduce thermal losses

- More efficiency boiler chemistry

- Lower blowdown losses

- Insulation

- Reduction in thermal losses from deaerator, steam and condensate piping, blowdown tank, etc.)

- Increase in the steam system thermal cycle efficiency of 12.8.%

- Low excess air levels produce lower flue gas exit temperatures that increase overall boiler efficiency

- On/off operation is difficult to quantify because yearly count of on/off operation data is not available.

- Thermal losses are estimated based on the size of the boiler and an estimated loss of uninsulated lines.

The combustion process will dictate the NOX reduction. There is a NOX reduction with new burners, but NOX data on the older boilers is not available.

– This article appeared in the Gas Technology supplement.