Over the past two decades Plant Engineering magazine has been publishing the entrants and winners in our Tips & Tricks competition. Since 1994 we have limited the winners to three, 1st, 2nd and 3rd place. Out of these winners we have selected the "best-of-the-best" to present to you now. These winners present novel solutions to everyday problems encountered by plant engineers.

Over the past two decades Plant Engineering magazine has been publishing the entrants and winners in our Tips & Tricks competition. Since 1994 we have limited the winners to three, 1st, 2nd and 3rd place. Out of these winners we have selected the “best-of-the-best” to present to you now.

These winners present novel solutions to everyday problems encountered by plant engineers. They are not just something that turned on a light in someone’s head but are based on sound engineering principles.

Some of the technical disciplines illustrated in Tips & Tricks are: water jet drilling of a hole, finding the center of a round piece by establishing a horizontal plane, using a furnace air filter to clean ambient air and the use of color to see beyond a machine guard.

Assembling hose fittings

Problem : Assembling push-on hose fittings is a tiring and time-consuming job. Is there an easier way to make these assemblies?

Solution : Cut a 12-inch piece of threaded rod that passes through the hose fitting. Insert the rod through the fitting and into the hose. Use vise grips to hold the rod in the hose. Put a flat washer and nut on the exposed rod and turn the nut to drive the fitting into place.

This tip was originally published in February 1995.

Hammering home the answer

Problem : Is there a quick way to back out a socket set or head screw when the internal hex or square drive is stripped?

Solution : Hammer a Torx drive socket slightly larger than the hex or square shape into the opening. The hardened edges of the Torx socket cuts into the screw and provides enough holding power for removal.

This tip was originally published in March 1998.

Sidewalk water drilling

Problem : Sometimes it is necessary to run cable under a sidewalk. Is there a way to do this without tearing up the sidewalk?

Solution : Dig a hole on each side of the sidewalk. Attach a water hose to a threaded PVC pipe and use water pressure to make a hole under the sidewalk. When finished, you have a pipe in place with threaded ends for cable connections.

This tip was originally published in March 2005.

Ceiling tile puller

Problem : Suspended ceilings make access to utilities easy because the tiles can be lifted out of the grid. But sometimes the tiles won’t drop back into place because of interference from suspension wires or light fixture clips. How can the tiles be put in place?

Solution : Use a wine bottle corkscrew to grip the tile from below and pull it down into place. A corkscrew with a lot of pitch works best.

This tip was originally published in March 2000.

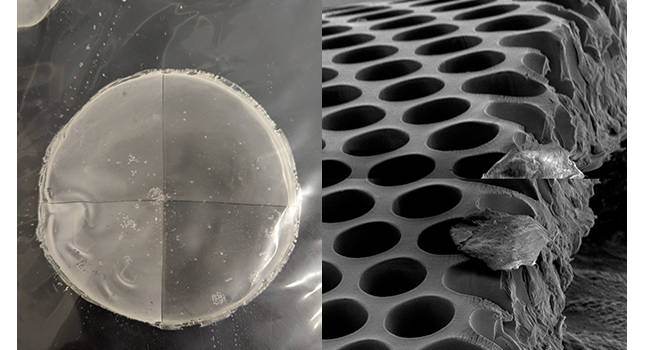

Seeing behind machine guards

Problem : It’s difficult to see things behind expanded metal machine guards, especially if the guards are painted a light color such as safety yellow or orange.

Solution : Paint the expanded metal portion of machine guards flat black. (Leave the frames painted with safety colors.) The flat black absorbs light, allowing you to see through the expanded metal to check for abnormalities.

This tip was originally published in March 2000.

Gone fishin’

Problem : A tool or other object falls into a 55-gallon drum of product. You can see it. Is there a way to retrieve the item without emptying the drum?

Solution : Make a noose, similar to one a dog-catcher uses, out of 316 stainless steel tubing and TIG wire. Bend the end of the noose at an angle to the tubing. To grab the item, pull the TIG wire.

This tip was originally published in December 2003.

Inflating plug

Problem : When a valve on an open tank doesn’t shut off, the entire inventory must be dumped to repair the problem. Can this expense be saved?

Solution : Install an inflatable pipe plug. Select a piece of pipe slightly smaller then the ID of the section to be plugged. Weld the end shut and drill a /-inch hole in the side. Cut a piece of tire inner tube to fit over the over this pipe. Use wire to seal the ends of the inner tube. From the top of the tank, insert the plug into the pipe opening. Apply about 5 psig of air pressure to inflate the plug. Now the valve can be replaced without losing the contents of the tank.

This tip was originally published in March 1999.

Drill through the center of round stock

Problem : A hole must be drilled through the center of round stock. Is there a way to determine where the center is quickly and easily?

Solution : Mark the axial location of the hole and clamp the part in a drill press vise. Place a thin strip of metal (6-inch steel rule, hacksaw blade, etc.) on the part. With the drill press off, lower the drill bit onto the metal strip, lightly squeezing it. Move the vise until the metal strip is level. That is the center of the round part.

This tip was originally published in February 2003.

Protecting the eyes

Problem : Drilling overhead often produces a cascade of shavings and dust. How can the driller protect his eyes and keep the residue from falling into delicate components?

Solution : Get a styrofoam cup from the cafeteria. Place the cup over the drill bit to capture the droppings.

This tip was originally published in February 1995.

Tapping in

Problem : Trying to pull a bushing frozen in a blind hole is frustrating and time consuming. Is there an easy way to remove the bushing?

Solution : Select a tap that fits the ID of the bushing and leaves enough material for threading. Glue a steel ball to the end of the tap. Wrench the tap down to the bottom of the hole. When it reaches the bottom, there is enough reaction to push the bushing out.

This tip was originally published in February 1997.

Holding onto screws

Problem : Inserting screws into small or tight places on a wall or overhead are often difficult and frustrating if you don’t have a magnetic screwdriver handy. There isn’t enough room for your fingers to hold onto small screws while trying to drive them home. Is there a way to get this job done?

Solution : Push the screw through a piece of paper; the threads hang onto it for you. Then hold the paper from the side and push the screw into place with the screwdriver. When the screw is in the hole, simply tear the paper away and finish tightening. This method works at any angle, even upside down.

This tip was originally published in February 2002.

Cleaning dirty air

Problem : When working in a dusty area or around sanding operations, dirt seems to be floating everywhere and settles on everything. Is there an economical way to capture the dust before it enters the plant environment?

Solution : A simple dust collection system can be made for less than $20. Get a 20-inch x 20-inch box fan, 20-inch x 20-inch furnace filter and four pieces of tape. Tape the filter on the suction side of the fan and position it near the dust-generating source or in the dusty area to capture the particulate. This filter position allows you to see when it needs cleaning or replacing and the airflow helps hold it in place.

This tip was originally published in February 2002.

Remove broken taps

Problem : Taps break off, especially when tapping a blind hole. Is there an easy way to remove the tap without damaging the piece part?

Solution : Build up a small welding bead on the top of the tap. Then slip a nut over the bead and weld the nut to the bead. Using a wrench, the tap should be easily extracted.

This tip was originally published in March 2005.

Tennis anyone?

Problem : Sometimes you have to run a wire above a suspended ceiling where the distance is greater than 30 feet. Is there an easy way to run the wire without disturbing the tiles?

Solution : Run a piece of string through a tennis ball. Throw the ball to the point where you want the wire. If the ball falls short, an observer can note which tile bounced. Pull the wire with the string.

This tip was originally published in December 2003.

Limit battery charge

Problem : The battery life of portable power tools is reduced if overcharged due to the battery overheating. How can this problem be eliminated?

Solution : Provide the correct number of charging hours by using an outlet timer. When the tool is picked up in the morning it will have the proper charge.

This tip was originally published in March 2005.

Eliminating drip

Problem : Using paint out of a can or bucket often gets messy. Each time the brush is wiped, paint runs down the outside and around the lip of the can. Is there a way to keep the can clean?

Solution : Place a large rubber band or strip of tape across the top of the can to wipe the brush on. Paint then drips into the container, eliminating the mess.

This tip was originally published in February 1997.

Gaskets stay put

Problem : Sometimes gaskets have to be installed in unusual and/or difficult locations. They may be awkward or impossible to hold in place while installing bolts. How can you get a gasket to stay in place when installing it in such a situation and adhesives can’t be used?

Solution : Hold the gasket in location against one surface and tie it in place with pieces of string located in opposite holes. Install bolts in the remaining holes, drawing the two surfaces close to each other. Cut and remove the strings. Install the remaining bolts and the job is done.

This tip was published in February 2003.

Keep screws handy

Problem : When using a lot of fastening screws, it is time consuming to reach for them one at a time from a box. Is there a better way to have the screws handy while doing this work?

Solution : Tape a magnet to the back of a drill. Dip the drill into the box of screws and dozens of them will stick to the magnet. They are now convenient to retrieve and do the job.

This tip was originally published in February 2003.

Locating a bad connection

Problem : How can I locate an intermittent bad connection?

Solution : Hook inline fuseholders across the suspect connections. Load the fuseholders with low current fuses that will not carry the load. If the connection breaks, the fuse blows, giving a visual indication of the failure, even if the connection starts to conduct again.

This tip was originally published in March 1998.

Leveling answer

Problem : Leveling machinery is often frustrating. Placing a level in the traditional right-to-left and front-to-back orientations does not always work. Is there another way to determine level?

Solution : Aim the level at diagonal adjusting screws or corners of the base if shims are used. Time spent in the leveling task is greatly reduced.

This tip was originally published in February 1996.