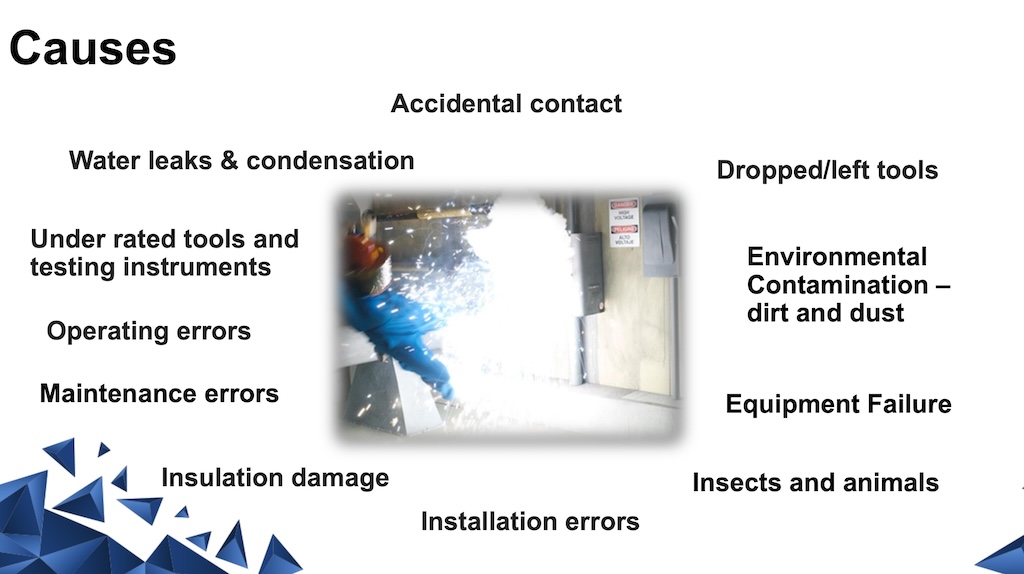

Arc flash continues to be a threat in the workplace. Codes exist to enable plants to protect workers – their most valuable asset. This online special report features expanded coverage from the May issue of Plant Engineering magazine.

Arc flash continues to be a threat in the workplace. Codes exist to enable plants to protect workers — their most valuable asset. This online special report features expanded coverage from the May issue of Plant Engineering magazine.

Five misconceptions about arc flash compliance There are some misconceptions in the application of OSHA regulations, NFPA Standards and IEEE guidelines relating to arc flash hazards and associated safety practices. If plant managers don’t properly apply these standards, they may compromise worker safety and risk OSHA violations.Read the full article .

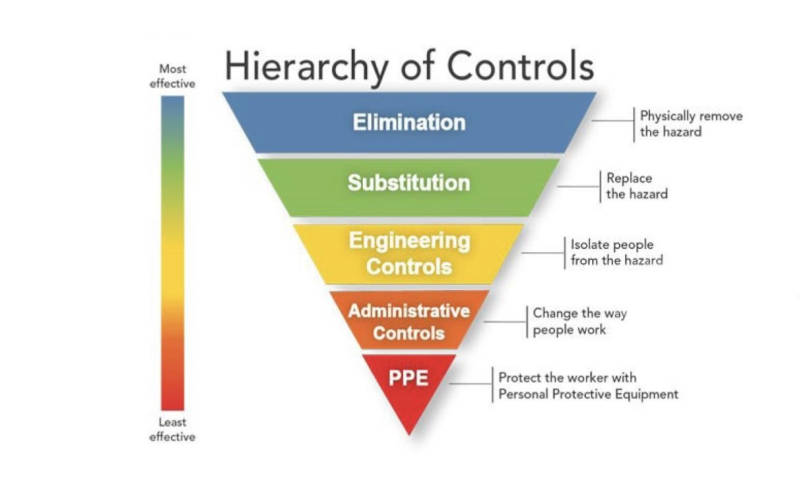

NFPA 70E urges industry to turn it off or put it on For more than three years the latest revision of NFPA 70E, “Standard for Electrical Safety in the Workplace,” has delivered a simple message: to work safely on electrical installations, turn off the power. And if you can’t avoid working on energized systems, put on the appropriate personal protective equipment to protect against the hazards of shock and arc flash. Sounds easy. But for some in the industry, it’s just not happening.Read the full article .

Five considerations for choosing an arc flash hazard analysis One of the critical steps to comply with NFPA 70E 2004 is commissioning a flash hazard analysis for your facility. This requirement affects almost all existing facilities that have electrical distribution systems that operate at 50 V or greater, which at some time may require maintenance or even a lockout/tagout procedure while the equipment is energized.Read the full article .