Predictive analytics success can be achieved through steps such as data acquisition, data ingestion, performance prediction and more.

The journey toward smart manufacturing through digitalization can seem overwhelming when we find ourselves mired in too many parameters and variables to analyze and simply too much data.

Big Data gets bigger and soon we are swimming in our own data lake!

Often there are self-doubts as to the direction we are going, and we tend to have second thoughts about the end results. It starts to feel like we are boiling the ocean, especially if the results are not promising.

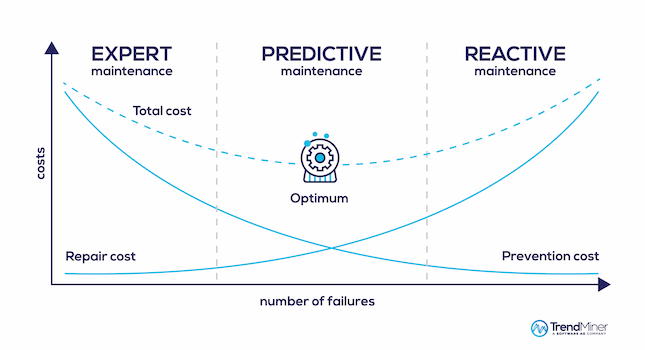

It therefore is crucial that we focus on concrete steps that move from the start to finish of a predictive analytics initiative. The result is a successful deployment of analytics that drives the manufacturing application towards a zero-downtime, zero-defects mindset and business case. Two areas, predictive maintenance (zero-downtime) and predictive quality (zero-defects), are the low-hanging fruit and the quickest wins for smart manufacturing today.

The time has come where the research in artificial intelligence (AI) and its underlying machine learning (ML) techniques are now available as a packaged product with solution templates that can be applied in practical manufacturing applications, such as robotics, computer numerical control (CNC) machine tools, molding, casting, and stamping presses.

Six steps towards a successful implementation of a “predictive analytics” project in manufacturing are the following:

- Connectivity and data acquisition – Select your critical machines and acquire relevant data parameters for that application via the machine CNC/PLC controls and add-on vibration or other type sensors.

- Data ingestion and processing – Consume the relevant data parameters into your data-lake and pre-process the data by cleansing, segmenting, removing outliers, and ensuring the integrity of the data for analytics

- Feature engineering – Apply statistical extraction and selection tools to convert the raw data into highly correlated features for training the AI/ML models.

- Health assessment – Quantify the health condition of the manufacturing equipment and determine warning and failure thresholds via an AI analytics model.

- Performance prediction and diagnosis – Determine the remaining useful life (RUL) of your equipment with a degree of prediction accuracy, and the root cause of failure (e.g., which axis on the robot, or which bearing failure mode on your CNC spindle).

- Prescriptive decision-making – Visualize health, RUL, and diagnostic information to end users for decision-making support, and in some cases, prescription of recommended actions like the need to tweak the machine program/recipe, or integrate the insights with the clients’ maintenance system to automatically create a predictive alert or work order and request spare parts.

Each step is critical to the overall success of the project and the acceptance of the results by the end-user community. The true measure of success will be justification of the business case for the analytics initiative by achieving a respectable return on investment (ROI).

Without a measurable payback, smart manufacturing will remain “research mode” and in pilot project purgatory of challenges to scale. The application of AI had to wait for the computing power, CPUs and RAM memory to reach the stage today where the processing speeds can sustain real-time computations of data and arrive at decisions in near real time.

Combined with the ability to route data and decisions across the internet, the real power of predictive analytics and AI can now be brought down to the users on the shop floor. Ultimately the end customer cares about an intuitive solution experience they can trust, and the value (business case), and not the AI/ML technology and algorithms.