In this 2023 study on motors and drives, product quality was the most important factor for selecting a product

Motors and drives insights

- The average respondent to the “Purchasing Considerations for Motors and Drives” study has 25 years in the plant engineering profession.

- Professionals with maintenance operations titles have the most influence (63%) for the purchase of motors and drives.

Product quality is the No. 1 influence on a plant professional when selecting a company or manufacturer of a new motor or drive. This isn’t surprising, considering respondents to a recent Plant Engineering study on “Purchasing Considerations for Motors and Drives” buy, specify, recommend or approve motors, drives and motor controls and power transmission.

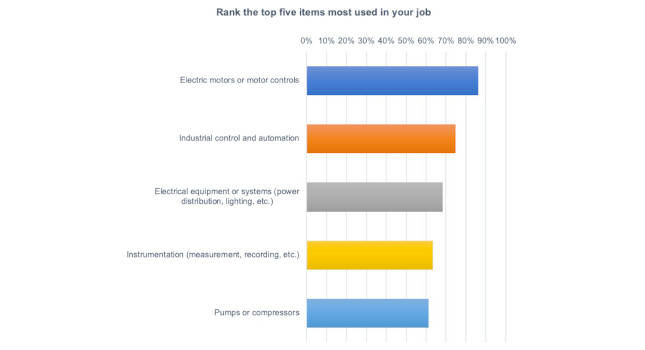

Motors and drives are used for a variety of reasons, with the top responses of:

-

Pumps: 83%

-

Fans: 73%

-

Compressors: 68%

-

Electrical equipment: 62%

-

Conveyors: 60%

-

HVAC: 55%

Respondents selected product quality as the most important 25% of the time, with the manufacturer’s reputation (14%) and lead/delivery time (12%) in second and third place, respectively. Quality is important for both new and replacement systems, which are split nearly evenly for 2022 projects. Money went to new systems 49% of the time; new implies a brand-new system, not previously available in the plant or manufacturing facility.

Additions of new motor and drive systems or replacements were done for a variety of reasons:

-

End-of-life replacement: 28%

-

Energy efficiency: 17%

-

System failure: 12%

-

New product line: 16%

-

Enlarged facility: 11%

When asked, “How is your time broken up when researching and purchasing motors and drives?” respondents indicated they spent the most time researching vendors and products (25%). Close behind were evaluating vendors, products and replies for quotes (22%), and writing specifications, requests for quotes (21%).

This closely matches with the information source most preferred when selecting a new motor or drive. The top two are:

-

Supplier/vendor websites: 28%

-

Online catalogs/directories: 25%

And once a vendor has been selected, the two keys to retaining business of a plant professional are:

-

Access to knowledgeable engineers, not the sales department: 71%

-

Provide good local support: 55%