Power-to-gas (P2G) technology can help produce renewable natural gas (RNG) without creating greenhouse gas emissions, but there are questions about how to make P2G work, mostly related to system optimization and electric grid integration; projects in the field and university research are working to answer those questions.

Over the last several years, renewable energy sources like photovoltaic (PV) solar and wind turbines have grown. In fact, in some states such as California, which have put a greater emphasis on green energy, at certain times of day there is more renewable electricity being generated than can be used. In 2018, California curtailed 461 gigawatt-hours of wind and solar energy due to this mismatch between supply and demand. For system operators and utilities, the challenge is finding a way to store the excess renewable energy produced during peak generation periods so it can be used in future peak demand periods.

One possible solution to both the renewable energy storage challenge and CO2 emissions is power-to-gas (P2G) technology. P2G uses surplus electricity to create renewable hydrogen or renewable natural gas (methane) that can then be stored in the natural gas pipeline system and then used to power a variety of end-uses such as boilers, engines and fuel cells. In doing so, P2G saves resources that would be spent on extremely expensive energy and CO2 capture and storage systems. P2G can harvest excess nuclear, wind, and solar power, which would otherwise be wasted or limited to low-value off-peak markets and recycle CO2 that would otherwise be emitted into the atmosphere.

There is no getting away from the fact that there is an urgent need and growing political demand to reduce the CO2 levels globally. It is alarming to note that even with the increasing global focus on reducing CO2, there is still significant use of fossil fuels and industrial processes causing an unsustainable increase of CO2 in the atmosphere.

How does it work?

SoCalGas and Enbridge Gas outlined the conversion process. Excess renewable electricity is used to convert water into renewable hydrogen by employing electrolysis. Electrolysis splits water (H2O) into hydrogen (H2) and oxygen (O2). This is a well established electrolyzer technology. While the oxygen is likely released into the atmosphere, the hydrogen is captured and can be blended with natural gas and stored in the pipeline system. However, O2 could have added value, for instance, if P2G is located at a wastewater treatment plant (WWTP), which would have use for O2 for water treatment.

While hydrogen is a non-greenhouse gas that has received a lot of attention as a possible energy source, its main drawback is the lack of experience and regulation blending H2 onto the pipeline.

Until H2 blending processes and protocols are established, companies are better off converting the renewable hydrogen into renewable natural gas (methane) by adding an additional step after the electrolysis process called methanation. When methanation is accomplished using a biological process, it is called biomethanation. In biomethanation renewable hydrogen is mixed with carbon dioxide (CO2) and fed into a bioreactor containing microbes call Archaea. Archaea consume the H2 and CO2 and generate methane (CH4), or renewable natural gas (RNG). The resultant RNG can then be injected into the natural gas pipeline system and then used in everything from home appliances to industrial processes, engines and power plants. Thus, the RNG synthesis process works by reacting the renewable hydrogen with captured CO2. At landfills and wastewater plants, it is preferable to convert the CO2 they produce to methane rather than separating from the biogas and releasing it into the air.

Thus, the RNG synthesis process works by reacting the renewable hydrogen with captured CO2. At landfills and wastewater plants, it is preferable to convert the CO2 they produce to methane rather than separating from the biogas.

Cost and viability concerns

While P2G technology has been around for some time, it’s still considered a “new” technology. However, that may be changing. Several P2G projects have come online in recent years, including:

- In June 2013, Audi announced its 6-MW P2G facility in Germany making it the first automaker to develop a chain of sustainable energy carriers. A press release stated that its e-gas project is a demonstration of how e-gas can be stored efficiently independent of location.

- In 2016, Electrochaea began operating its 1 MW BioCat P2G project in Avedøre, Denmark.

- In 2019, Electrochaea began operating a second 1 MW P2G project in Solothurn, Switzerland.

- In 2019, France announced five P2G demonstrations.https://aer-bfc.com/en/bourgogne-franche-comte/sectors/hydrogen/

- Construction of Japan’s first P2G plant was initiated in July 2017 as a key part of its efforts to reduce CO2 emissions. The press released mentioned how the objective of the facility was to test and prove that large-scale P2G plants are, in fact, feasible from an environmental and economic perspective.

Utility-scale P2G facility developed

A June 2019 presentation to the Energy Solutions Center (ESC) highlighted Enbridge’s Markham Energy Storage Project in Ontario. The project is focused on creating the first utility-scale P2G facility with a 2.5-MW with 8 MWh of H2 storage. Commercial operations, which started in May 2018, are designed to provide stable service to the independent electricity system operator (ISO). The project will evolve to provide renewable H2 for injection into the local natural gas network.

Technology accuracy is key because minimum to maximum load swings are achieved in milliseconds. It is a very much a “blink and you’ll miss it” kind of circumstance and this has a significant impact.

So far, real-life operations confirm the P2G’s real-time response to the automatic generator control (AGC) is very fast and accurate. This accuracy, in addition to improving safety, can help integrate more renewables like wind and solar and reduce GHG emissions as well as consumer costs.

The project includes a pilot program for a controlled hydrogen injection area. This is designed to manage hydrogen concentrations to a targeted range to compare against predicted engineering forecasts.

As a result, a portion of the distribution system will be isolated and hydrogen will be injected into the distributed system at controlled levels of less than 5%. The reason for the low level is to confirm this blend can be considered a drop-in fuel and that there won’t be any safety or quality issues.

The pilot program will start with 3,500 Ontario-area customers receiving blended gas and it can be expanded to 30,000 customers if additional project learning is needed.

Pilot program launched for bioreactor

In 2014, SoCalGas and Department of Energy’s (DOE) National Renewable Energy Laboratory (NREL) collaborated in developing the first U.S.-based P2G project. This project was inspired by the belief that renewable energy curtailments would continue to be a problem and impediment to wind and solar penetration. Integrating the electric grid and natural gas system, which could be used to store energy, could create tremendous long-term value for the project.

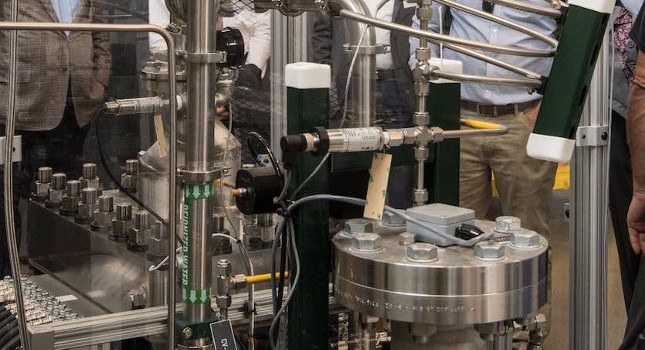

Outside NREL’s Energy Systems Integration Facility (ESIF), where pipes carrying hydrogen line the exterior of the building, is a 25-foot tall cylindrical bioreactor system is now converting hydrogen and carbon dioxide into methane. After a careful commercialization process, the plant has achieved hydrogen-to-methane conversion rates in excess of 95%. The process relies on a heat- and gas-loving archaon, originally extracted from a geyser basin in Iceland, to accomplish that conversion.

Kevin Harrison, program manager – Research, Energy Systems Integration, leads researchers and guests from NREL, DOE, SoCalGas, Sempra Utilities and Electrochaea, on a tour of the hydrogen facility at the Energy Systems Integration Facility at NREL. Courtesy: Dennis Schroeder, NREL[/caption]

The success of the NREL project has led to several planned commercial projects. The testing campaigns will be used to improve the design and operations of future plans. The NREL project will also be used to help inform future projects through public policies, laws, grid operating protocols and commercial tariffs.

University researchers turning greenhouse gases to liquid fuel

In the laboratory, researchers are working to make greenhouse gases viable energy that can be stored and used for commercial applications.

Rice University researchers, in conjunction with Brookhaven National Laboratory, have developed a catalytic reactor that uses CO2 as its feedstock and produces highly purified concentrations of formic acid, according to a Rice University press release. In their tests, their electrocatalyst reached an energy conversion of efficiency of 42%. This means nearly half of the electrical energy can be stored in formic acid as liquid fuel.

“Formic acid is an energy carrier,” said Haotian Wang, a chemical and biomolecular engineer at Rice University. “It’s a fuel-cell fuel that can generate electricity and emit carbon dioxide – which you can grab and recycle again. It’s also fundamental in the chemical engineering industry as a feedstock for other chemicals, and a storage material for hydrogen that can hold nearly 1,000 times the energy of the same volume of hydrogen gas, which is difficult to compress. That’s currently a big challenge for hydrogen fuel-cell cars.”

Two advances made the device possible, according to Rice postdoctoral researcher Chuan Xia. The first was the development of a robust, two-dimensional bismuth catalyst; the second was a solid-state electrolyte that eliminates the need for salt as part of the reaction.

With its current reactor, the lab generated formic acid continuously for 100 hours with negligible degradation of the reactor’s components, including the nanoscale catalysts. Wang suggested the reactor could be easily retooled to produce such higher-value products as acetic acid, ethanol or propanol fuels.

Next-generation RNG

RNG can improve customer access and affordability to low-carbon energy supplies, and P2G can help companies achieve this in the short-term. And as RNG solutions evolve, the technologies and methods developed through current projects will allow greater energy savings to be realized.

– This article appeared in the Gas Technology supplement.

MORE INFO

https://www3.socalgas.com/smart-energy/renewable-gas/power-to-gas

https://www.cleanenergywire.org/factsheets/power-gas-fix-all-problems-or-simply-too-expensive

https://www.nrel.gov/news/features/2017/undersea-microbes-provide-path-to-energy-storage.html