Solution identifies production and equipment problems before they become apparent.

In the fourth quarter of 2018, eLynx Technologies announced the commercial launch of a suite of predictive maintenance software products and services the company says will revolutionize the upstream oil & gas industry.

Use of predictive analytics as a service (PAaaS) will be the means to predict equipment breakdowns and downhole events such as liquid loading. A plunger lift predictive maintenance product introduced in September was followed in November with a solution for electrical submersible pumps.

As an early provider of SCADA as a service, eLynx compiled a vast store of fully normalized well operating data, ready for exploitation by the analytics and machine learning applications taking hold today in oil & gas and other industries.

“We are the fortuitous beneficiary of almost 20 years of industry knowledge gained from monitoring over 40,000 wells for hundreds of customers in all major U.S. drilling basins. We now are leveraging that knowledge,” said eLynx founder and CEO Steve Jackson.

The industry’s relentless march of mergers and acquisitions over that same time period prevented the same rigor being applied to other oil & gas assets, as personnel and technologies frequently changed over.

To take advantage of the compiled data, over the last several years, eLynx invested heavily in human assets having expertise in the data sciences. “It takes powerful minds to turn data into valuable products, and we have built one of the most potent data analytics teams in the United States,” Jackson said.

PAaaS promises to save companies capital, boost reserves, reduce waste, enhance safety, and protect the environment. “We will increase users’ revenue valuations based on increased average flow,” Jackson said.

In initial trials, the plunger lift predictive maintenance product saved one producer more than $700 per month per well. For a 500-well field, that translates into $4.2 million in annual savings. This early experiment represents just a sliver of what eLynx said it will deliver to its customers through the combination of predictive analytics as a service and SCADA.

Plunger lift and ESPs

Although found in both oil and gas wells, today a plunger lift is typically used in deliquefying a natural gas well.

As is well known, the plunger is used to remove from productive gas wells contaminants that include water, sand, oil, and wax. As they mature, gas wells exhibit a decrease in bottomhole pressures and production velocities less than ideal for carrying liquids-produced water, oil, and condensates to the surface. Over time, this liquid accumulates in the production tubing downhole, creating a condition known as liquid loading.

Plunger lift, as an artificial lift method, is a way to remove liquids from aging gas wells. Plunger lift controls regulate the cycling of a motor valve in response to plunger arrival at the well head, line pressures, liquid levels, or pressure differentials.

The electrical submersible pump (ESP) is an efficient and reliable artificial-lift method for lifting moderate to high volumes of fluids from wellbores.

To ensure optimal ESP performance, operators install downhole sensors that continuously acquire real-time system measurements such as pump intake and discharge pressures and temperatures, vibration, and current leakage rate.

Typically, users monitor pumps through SCADA systems, which act as central repositories of data from all downhole sensors. Anomalous readings lead to changed pump settings.

Ongoing innovation

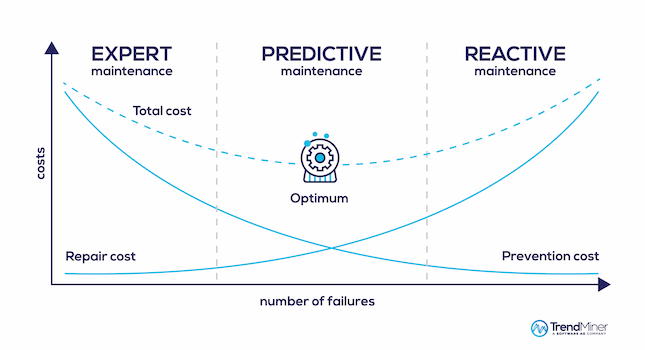

As might be expected from a machine learning application, to start, use of predictive analytics as a service application initially will anticipate operating challenges based on anomalous operating conditions. Over time an application will more precisely identify the bad actors responsible for the adverse conditions. The eventual goal is the kind of prescriptive analytics that will recommend actions to be taken in response to identified challenges.

Plunger lift was the first application tackled because of its cyclical nature, with solutions for the more complex challenges of rod pump and gas lift scheduled for release in 2019.

“Almost 20 years ago, eLynx introduced SCADA as a service to the industry,” said Samantha McPheter, eLynx chief product officer. “With these new technologies, we move to predictive analytics, a pivot that vaults data from something merely important to essential for companies seeking to be competitive in this new environment. Companies that are slow to adapt to this new reality will be consumed by competitors that are quick to embrace this data revolution.”