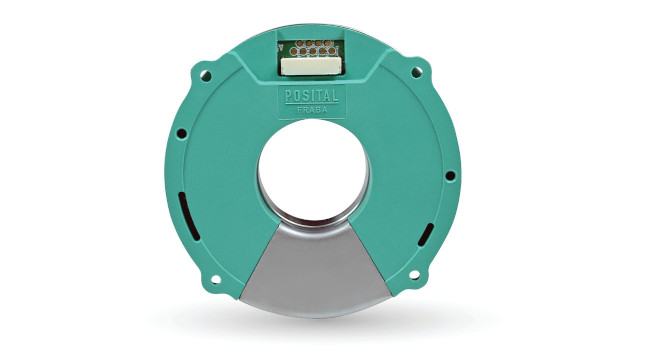

Recent research by Venture Development Corporation (VDC) has found that the levels of requirements for many features of linear displacement sensors are generally low. According to the seventh edition of VDC’s North American Markets for Linear Displacement Sensors , 74% of users surveyed cited no current requirements for sensor diagnostics.

Self testing was the most required feature identified, but only by 10% of user respondents. Of the other diagnostics required, the next most cited included calibration checking, accuracy checking and signal strength indication.

Users were also asked to identify future additional diagnostic requirements in their linear displacement sensor procurements, beyond those identified as currently required. Nearly 80% of users stated no additional requirements expected by 2007. Self testing was again the most identified requirement, with 6% of users expecting to require this feature in the near term. Smaller shares of users identified a myriad of other requirements expected to be required in 2007. These included:

Accuracy checking

Calibration checking

Fault annunciation

Obstruction indication

Open circuit indication

Reference point checking

Repeatability checking

Sensor function checking

Short circuit indication

Target out of range indication

“Although users’ current requirements for diagnostic features on linear displacement sensors are relatively low,” said VDC analyst Jake Millette, “a growing number expect such requirements in the near to medium term. It is vital for vendors to continue to investigate and expand on the offering of these options.” Millette added that the general interest level in diagnostics and other features was high among users and that lack of information on the cost and benefits has likely limited the proliferation of these features to date.

For more information, click here