Key concepts Temperature control systems consist of four basic components-energy source, sensor, load, and controller-joined to form a closed-loop system.

Key concepts

Temperature control systems consist of four basic components-energy source, sensor, load, and controller-joined to form a closed-loop system.

Data from sensors can be transmitted to a controller, and then to other devices or networks.

Software allows easy communication to help simplify setup parameters, monitor processes, and collect data.

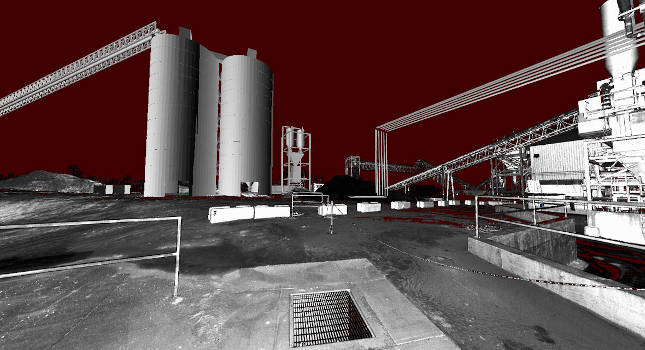

Whether your plant molds plastic containers, applies adhesives, extrudes plastic films, powder-coats automobile parts, or is involved in other thermal process applications, adequate controls are needed to ensure that an acceptable product is produced.

Temperature control system basics

A temperature process control system consists of four basic components, which are joined to form a closed-loop system.

-

Heater or cooler provides the heating or cooling energy to the system.

-

-

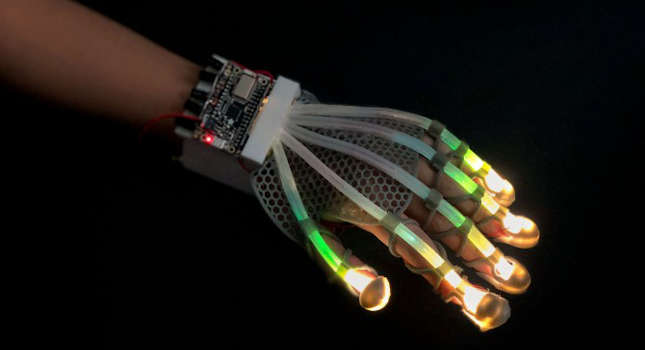

Sensor measures the temperature or other process variables (humidity, pressure, etc.) of the system, and feeds the information back to the controller.

-

-

Load is the object whose temperature or other parameter is to be maintained at a constant, specified value. The load absorbs the energy produced by the heater or cooler.

-

-

Controller compares the information received from the sensor with the desired temperature (setpoint) or process value. The task of the controller is to regulate the power supplied to the load, based on the demand of the system. The controller automatically adjusts the power fed to the heater or cooler to compensate for any tendency of the load temperature to drift up or down, thus closing the loop.

-

Trend toward communication

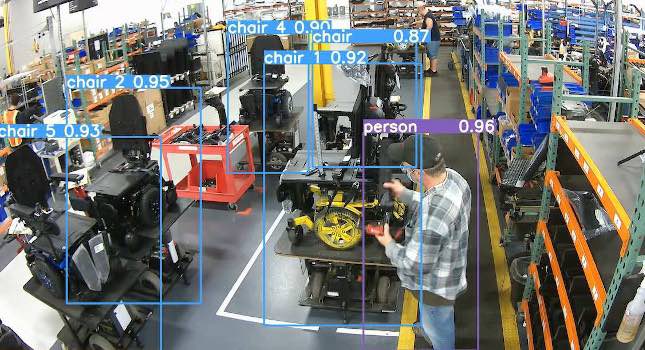

Technological advancements in communications continue to escalate. These advancements can help improve thermal manufacturing processes. The distribution of information from input, such as a sensor, to a central location where decisions can be made, is the role of the communications system. Data from sensors located in the manufacturing process can be transmitted to a controller, then to a printer, disk drive, or even a remotely located terminal or computer, which can be part of a local area network (LAN).

Controllers are typically connected using RS-232, RS-422, or RS-485 serial communication and an existing RS-232 serial port on a computer. RS-232 refers to the Electronic Industries Association’s (EIA) recommended standard for the mechanical and electrical interface, which specifies a DB-25 connector. This type of serial transmission is designed to communicate between one computer and one controller, and is usually limited to lengths up to 50 ft.

The RS-422 and RS-485 serial transmission types are designed to communicate between one computer and multiple controllers and have a high level of noise immunity. They are usually limited to lengths of 650 ft for RS-485, or 1650 ft for RS-422.

Device-level buses have become predominant types of networks in industrial automation. These buses, or networks, are a type of communications link which connect industrial devices, such as sensors, switches, or panel displays to a controller, such as a PLC or computer. Popular general-purpose buses include DeviceNet and Profibus.

Software’s role

Industrial processes frequently require the precise control of temperature, humidity, motor speeds, or other parameters. Managing this type of operation and amount of information can be a difficult task at times. Recent advances in software technology are helping manage temperature and industrial processes more efficiently and increasing cost savings.

Software allows easy communication to help simplify setup parameters, monitor processes, and collect data. These data can then be used to improve a process by reducing manufacturing down time and wasted product, and predict equipment malfunctions.

Setup

Temperature or process controllers in a manufacturing process must be programmed to know what parameter values they should be monitoring, and what course of action (turn the heating elements off, ring an alarm, etc.) to take when a process value deviates from the specification tolerances. As time and technology have advanced, controllers have become more complex to program.

Software can be used to simplify the setup parameters in an industrial process. It allows users to program controllers through their PCs, instead of the traditional method of using the front panel keys. This approach can save a significant amount of time and money, especially if a user has a large number of applications or uses a variety of controllers.

This initial setup data can also be saved and quickly cloned into other controllers if future demand requires the expansion of a process to other controllers.

Monitoring

Having timely access to accurate data is critical to ensure that a product is manufactured with acceptable and consistent results. Having the tools to monitor manufacturing equipment and processes is of great importance in avoiding or fixing problems.

Continuous, live monitoring allows users to check, test, and modify an application’s operation instantly, and can flag alarms when problems occur so that plant personnel can correct them. Temperature loops can be monitored from a single location.

Remote monitoring via the internet should prove to be a powerful new tool during the next several years. This method will allow remote access to a company’s process information so that corrective action can be taken quickly in case of a problem, and expensive travel costs can be avoided.

Datalogging and trend analysis

Datalogging refers to the recording of key parameters, such as setpoints and process values, into a computer database. The temperatures a product experiences during the course of a manufacturing operation can be monitored, recorded, and charted using software.

A typical reporting chart shows temperature plotted along the vertical axis and time along the horizontal axis. These data can then be reviewed and analyzed to search for the cause of past problems or to predict future trends in a process. Potential areas of improvement, such as changes in maintenance schedules, can also be determined. These data are usually saved in an ASCII file type so that they can be exported later into other programs, such as statistical process control (SPC) software.

Regardless of the product a manufacturer produces, the ability for temperature or process controllers at the actual manufacturing workstation to communicate with a PC or PC network is key to reducing downtime and increasing productivity. Software can make an effective interface between the factory floor and a central decision making location, where manufacturing process information can be monitored and reviewed.

-Edited by Jack Smith, Senior Editor, 630-320-7147, [email protected]

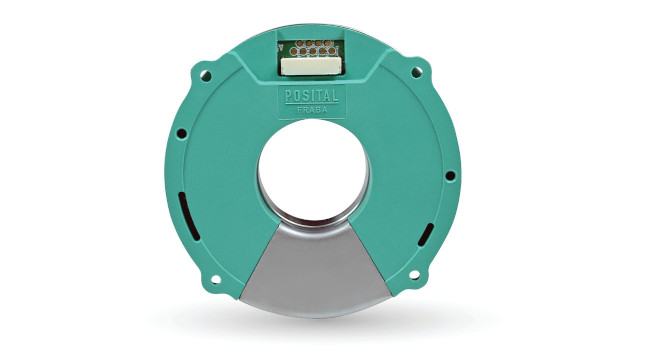

How control systems work The electronic temperature controller receives a signal from a temperature sensor, compares this sensor signal with the setpoint, and then supplies an output signal to the power controller.

The power controller heats or cools furnaces or vessels using an actuation device, such as a solenoid, fuel valve, or other methods of switching or regulating electrical currents supplied to heaters or controllers.

The temperature sensor consists of an element protected by a well or pipe. The sensor converts physical temperature to electrical signals. It is located in places where temperature control is desired.

-

-

-