Adding multi-turn measurement capabilities to hollow-shaft encoders used to be challenging, but adding a Wiegand wire system makes it easier and expands usable applications, including robotics.

Learning Objectives

- Hollow-shaft encoders are used for many motion control applications, but are often limited by how many turns they can perform.

- The Wiegand effect allows hollow-shaft encoders to make multiple turns, which increase the number of applications they can be used for.

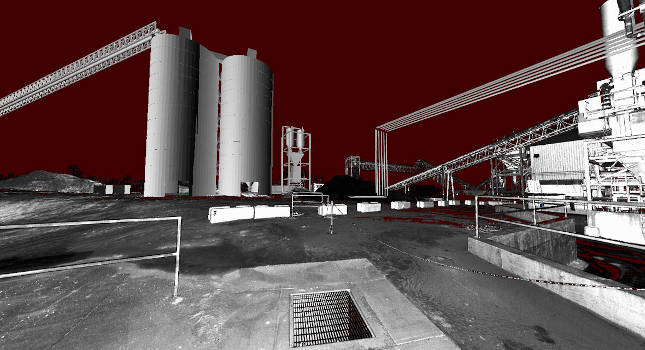

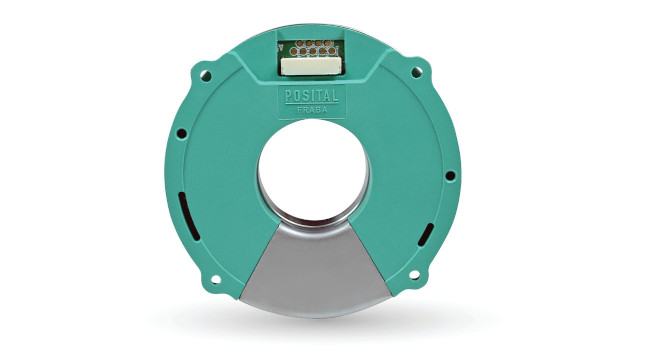

Ring-shaped (hollow-shaft) encoders can be an attractive alternative for motion control applications where their open center form-factor gives engineers extra flexibility when laying out their designs. In the past though, most encoders of this type have been limited to a single turn measurement range. A new generation of hollow-shaft encoders has overcome this limitation thanks to a zero-maintenance Wiegand-powered multi-turn rotation counting system.

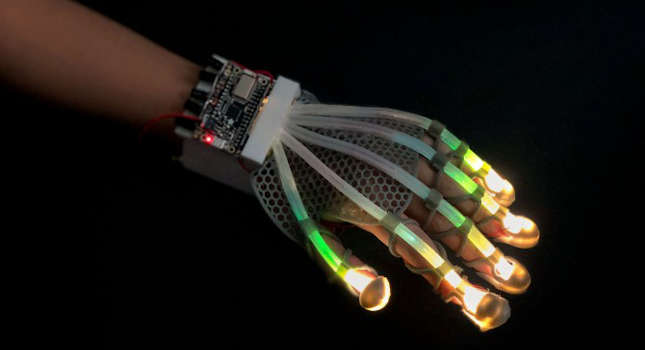

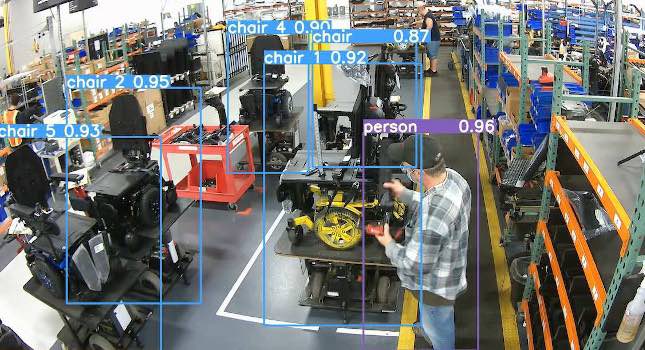

Hollow-shaft encoders fill an important niche in motion control, providing designers of servomotors, drives and robots with options for building position feedback sensors into their products. This type of encoder features a large central opening, which makes it convenient to install them on the driveshaft end of motors or gear units. Hollow-shaft encoders also are well suited to robots where they can be built into joints to measure arm positions directly. Here, their open-center form factor leaves room for structural elements or to route wires or pneumatic/hydraulic lines through the center of the joint.

Adding multi-turn measurement capabilities to hollow-shaft encoders is a plus for many applications, such as when the motor is connected to a reduction gear system or cable spool. For robots, a multi-turn measurement range is ideal for joints with a range of travel of over 360 degrees. Until recently, adding multi-turn capabilities to hollow-shaft encoder has been challenging due to their open center shape. This difficulty has been overcome by adapting a Wiegand wire system, which uses the rotation of a set of magnets to trigger a rotation counter system built into the encoders. A special advantage of this approach is the counter system is largely self-powered, eliminating the need for troublesome backup batteries or bulky, complex gear systems.

Capacitive encoder technology

Hollow-shaft encoders with large center openings are often based on capacitive measurement technologies since – unlike magnetic technologies – this approach does not require elements to be located on the center line of the instrument. Capacitive encoders have rotor and stator components, both shaped like flattened rings. The facing surfaces of these components have specially patterned conductive surfaces, which function as capacitor plates.

As the rotor turns, these conductive patterns change their relative positions, altering the capacitive coupling across the system. This modulates the amplitude and phase angle of mid-frequency electrical signals transmitted through the capacitor system. These signal variations are decoded to determine the rotor’s angular position. Accuracy is very high, with a 19-bit resolution. Since capacitance is averaged around the full circumference of the ring-shaped rotor and stator components, this system is relatively insensitive to small alignment errors or the presence of moisture or dust.

Adding multi-turn capability to encoders

The key to the multi-turn measurement range is a counter system powered by energy harvested from the motion of the rotor element. While Wiegand energy harvesting systems have often made use of a permanent magnet mounted on the centerline of a drive shaft, a completely new setup had to be found for the hollow-shaft design. Extensive field tests and magnetic field simulations resulted in an arrangement of four permanent magnets mounted on the circumference of the rotor.

These magnets create a stable magnetic field that turns with the rotor. As the rotor turns, a Wiegand sensor mounted on the stator responds to changing magnetic field and generates pulses of electric current that activate the counting electronics, precisely recording every revolution. This interface is supported by many standard PLCs and microcontrollers and requires no licensing arrangements.

Energy harvesting and the Wiegand effect

Energy harvesting refers to techniques for collecting electrical energy directly from the local environments, reducing the need for backup batteries and their attendant maintenance requirements.

While piezo systems, thermal and kinetic processes have set the pace for energy harvesting, the Wiegand effect, named for the U.S. inventor John Wiegand, is still considered an exotic alternative. The core of the Wiegand system is a short length of specially-conditioned Vicalloy wire. At the end of a complex manufacturing process, involving cold forming and tempering, the wire emerges with a soft magnetic core surrounded by a magnetically hard layer. This combination has a special feature. When the Wiegand wire is exposed to a changing external magnetic field, the magnetic polarity of the wire will reverse when the intensity of the magnetic field around the wire reaches a certain threshold. This sudden change of magnetic polarity can be harnessed to generate a pulse of electric current in a fine copper coil wrapped around the wire.

This technology has been used for energy harvesting since 2005 and an important factor for this breakthrough in energy harvesting was the availability of ultra-efficient low-power electronic chips.

Energy harvesting using the Wiegand effect is magnetically induced directly from the rotary motion. Unlike a dynamo, energy is produced with each turn is consistent – even for near-zero rotation speeds. A Wiegand sensor is 15 mm long and yield almost 200 nJ of energy at 7 V – enough to reliably activate the rotation counters and associated electronics.

Christian Fell is director of technology development, Posital-Fraba Inc. Edited by Chris Vavra, associate editor, Control Engineering, CFE Media and Technology, [email protected].

MORE ANSWERS

Keywords: Encoders, motion control

CONSIDER THIS

What applications would benefit most from hollow-shaft encoders in your plant?