Learn about the NFPA 70E “point of work” concept, which focuses on the need for proactive electrical safety measures where the work is performed

Learning Objectives

- Grasp the updates in NFPA 70E-2024, particularly the emphasis on “point of work” safety practices.

- Understand the placement and importance of permanent electrical safety devices (PESDs) in enhancing electrical safety and compliance.

- Learn about the advancements in lockout/tagout (LOTO) safety procedures and their critical role in preventing workplace electrical hazards.

NFPA 70E insights

- Explore the critical updates in NFPA 70E-2024, emphasizing the “point of work” concept and understand the integral role of permanent electrical safety devices (PESDs) within the hierarchy of risk controls.

- This article delves into how these elements, alongside robust lockout/tagout (LOTO) procedures, can significantly uplift electrical safety standards in the workplace.

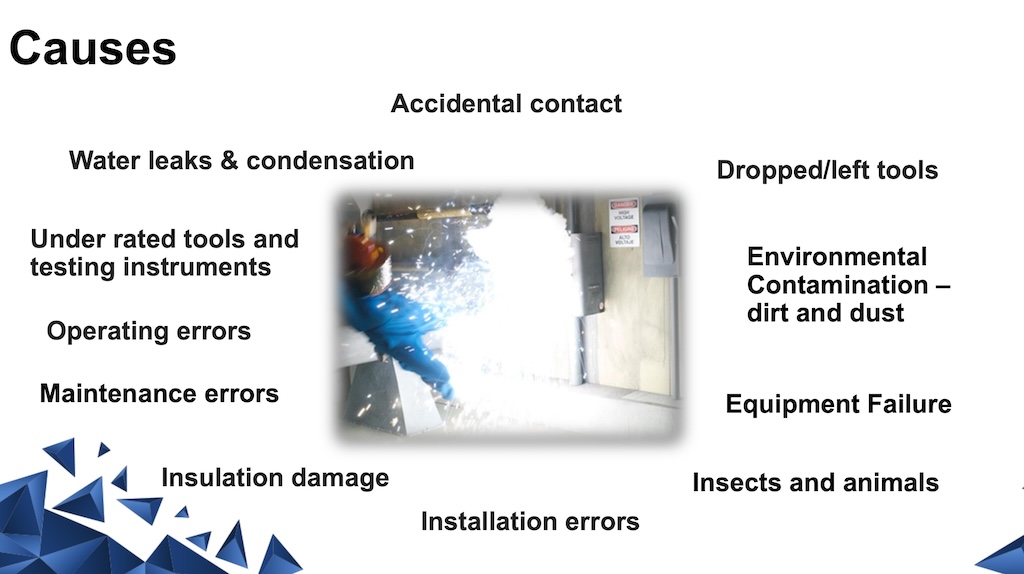

Staying ahead of the latest standards and technologies is not just about compliance — it’s about protecting lives. The 2024 updates to NFPA 70E: Standard for Electrical Safety in the Workplace bring to the forefront the “point of work” concept, emphasizing the need for proactive safety measures right where the work is performed. This concept underscores the importance of assessing risks and implementing controls before any electrical work begins, ensuring that safety is not an afterthought but a fundamental part of the work process.

How NFPA 70E ensures electrically safe work conditions

The process for establishing and verifying an electrically safe work condition, as outlined in NFPA 70E Article 120.6, is a comprehensive procedure aimed at ensuring the safety of workers handling electrical equipment. It involves identifying all electrical sources, opening the disconnecting device(s) for each source, ensuring disconnection, verifying the disconnection visually, releasing stored electrical and nonelectrical energy, applying lockout/tagout (LOTO) procedures and using a test instrument to verify the absence of voltage. These seven steps, followed in sequence, are critical for maintaining a safe work environment and are aligned with the principles of NFPA 70E, which emphasizes the importance of safety in electrical work practices.

Permanent electrical safety devices (PESDs) listed to UL 61010: Safety Requirements for Electrical Equipment For Measurement, Control, and Laboratory Use can play a vital role in this process by providing a means to verify the absence of voltage without direct exposure to electrical hazards, thereby supporting compliance with NFPA 70E’s approach to electrical safety.

Specifically, when used with an adequately rated portable test instrument, test point PESDs help in the verification process of the absence of voltage, complementing step seven of the LOTO process by allowing for safer and more efficient verification before and after work is performed. This enhances compliance with NFPA 70E by integrating technology that makes the verification process less invasive and reduces the risk of exposure to electrical hazards.

Compliance with NFPA 70E language: ‘point of work’

PESDs comply with NFPA 70E-2024 language and its emphasis on the “point of work” by providing strategically designed solutions that enhance safety directly at the work site. Their proper placement, compliance with safety standards, role in LOTO procedures and facilitation of safe voltage testing embody the principles of electrical safety at the point of work, ensuring a safer environment for electrical maintenance and repair activities.

Here’s how PESDs align with the “point of work” concept as articulated in NFPA 70E-2024:

- Proper placement and accessibility: PESDs should be installed in locations that are both practical and precise, ensuring that they are readily accessible at the point where electrical work is conducted. This placement is pivotal for maximizing their effectiveness in promoting electrical safety and aligns with the “point of work” concept by mitigating risks directly where the electrical work occurs.

- Compliance with NFPA 70E requirements: PESDs and other test point devices are recognized as compliant with the safety standards set by NFPA 70E. They provide a safe and efficient method for verifying the absence of voltage, which is a crucial step in establishing an electrically safe work condition. Their design and application are in harmony with the NFPA 70E’s emphasis on verifying an electrically safe work condition at each point of work, underscoring their role in adherence to updated safety protocols.

- Enhanced safety during LOTO procedures: Incorporating visible PESDs such as voltage presence indicators and absence of voltage test points can significantly reduce risks during LOTO procedures. By enabling effective and reliable verification of voltage status within an electrical panel or system, PESDs serve as an additional layer of protection, ensuring that workers can make informed decisions about the safety of their work environment. This is particularly relevant to the “point of work,” where ensuring the absence of hazardous energy is paramount.

- Facilitating safe and accurate absence of voltage testing: The NFPA 70E revisions validate the use of impedance-protected test points, a feature of many PESDs, for absence of voltage testing. This functionality is critical for safely establishing an electrically safe work condition, directly supporting the “point of work” philosophy by enabling precise testing at the location of the electrical work.

As industries continue to evolve and electrical systems become more complex, the need for comprehensive safety standards that address the realities of modern electrical work is paramount. The NFPA 70E 2024 updates, with their focus on “point of work” safety, PESDs and enhanced LOTO procedures, represent a significant step forward in meeting this need. By adhering to these standards and embracing the technologies and practices they advocate, employers and safety professionals can ensure that their electrical safety programs are not just compliant, but truly effective in protecting workers from harm.

Rethinking risk with the hierarchy of controls

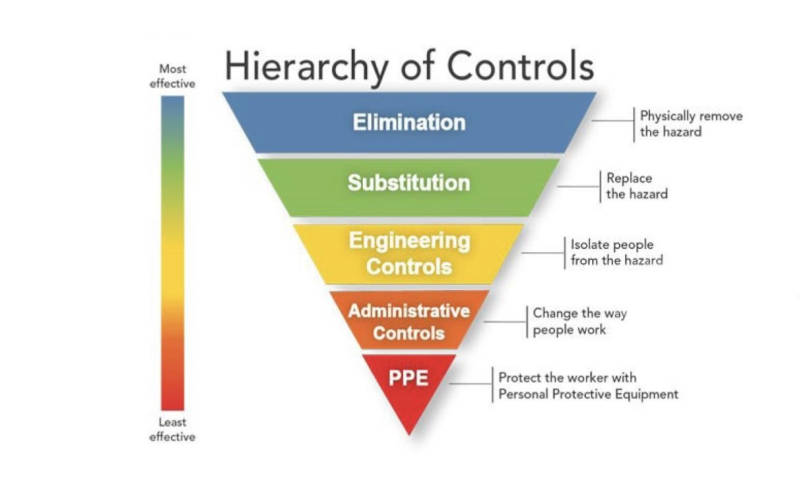

One of the cornerstones to any electrical safety program is the approach to the hierarchy of controls. Traditionally, this hierarchy has guided employers and safety professionals to prioritize elimination and substitution over administrative controls and personal protective equipment (PPE).

PESDs are an essential part of the engineering controls within the hierarchy of controls in industrial safety. The hierarchy of controls is a system used in occupational health and safety to minimize or eliminate exposure to hazards. It is represented as a pyramid with the most effective methods of control at the top and the least effective at the bottom. Here’s where PESDs fit in:

- Elimination: Physically removing the hazard and is the most effective control method. While PESDs don’t eliminate electrical hazards, they significantly minimize the need for interaction with live circuits, indirectly contributing to elimination.

- Substitution: Substituting hazardous situations with less hazardous ones can be partly achieved by using PESDs, as they can replace more hazardous voltage testing methods that require direct interaction with live circuits.

- Engineering controls: This is where PESDs are directly applicable. They are designed to isolate workers from electrical hazards by providing a way to verify the presence or absence of voltage without exposing workers to live electrical components. For example, PESDs allow verification from outside a closed electrical panel, reducing the risk of arc flash and shock.

- Administrative controls: These involve changing the way people work and include safety training and procedure modifications. While PESDs themselves are not administrative controls, they are often incorporated into safety procedures, thus supporting these controls.

- Personal protective equipment (PPE): This is the last line of defense and the least effective control method. PESDs can reduce the need for PPE by minimizing exposure to hazards, although PPE may still be required during certain operations for additional safety.

By integrating PESDs into electrical safety protocols organizations can significantly enhance their safety measures, align with best practices and comply with standards such as NFPA 70E. These devices are a proactive measure that aligns with the philosophy of designing safety into work practices and the working environment.

Integrating enhanced electrical safety program measures

The integration of PESDs into an electrical safety program represents a significant shift toward safer and more reliable electrical maintenance practices. By providing a means to verify the absence of voltage without exposing workers to live components, PESDs align perfectly with the NFPA’s increased emphasis on “point of work” safety. This approach not only enhances compliance but also significantly bolsters the overall safety and productivity of electrical maintenance operations.

NFPA 70E 2024 places a strong emphasis on training and competency. It mandates that workers involved in electrical tasks be not only adequately trained but also fully competent in the specific safety procedures relevant to their tasks. This includes a thorough understanding of the use and benefits of PESDs, the application of LOTO procedures and the ability to recognize and mitigate electrical hazards effectively.

Incorporating PESDs into the hierarchy of risk controls presents an opportunity to significantly reduce electrical hazards. These devices serve as a critical barrier between electrical workers and potential sources of electrical energy, ensuring that safety measures are not just reactive but inherently built into the system. Their use, combined with stringent LOTO practices, forms a robust defense against electrical accidents, aligning with the NFPA 70E’s goal of creating safer work environments.

Practical implementation of NFPA 70E

Implementing NFPA 70E-2024 updates begins with a thorough assessment of current electrical safety programs against the new standards. For PESDs, this involves identifying key areas where these devices can be integrated to ensure voltage verification processes are both efficient and comprehensive. Training sessions tailored to these updates can empower workers with the knowledge to apply “point of work” safety principles effectively.

A comprehensive overhaul of LOTO procedures, aligned with the latest NFPA 70E guidelines, has helped organizations strengthen their safety culture, demonstrating the tangible benefits of adherence to updated safety practices.

Training and competency development

Developing a robust training program is essential for ensuring that workers are not only aware of the NFPA 70E-2024 changes but are also competent in applying these standards in their daily tasks. This includes practical training on the correct use of PESDs and an understanding of enhanced LOTO procedures. Competency checks and refresher courses can help maintain a high level of safety awareness and compliance.

In 2023, the Occupational Health and Safety Administration (OSHA) reported significant violations related to the control of hazardous energy, underlining a critical need for improved safety practices in workplaces. Here is a summary for the key areas of concern and the solutions to address these OSHA violations:

Energy control procedure (730 violations): Difficulty in creating or updating detailed, equipment-specific energy control procedures and ensuring their consistent application and communication.

Solution: Develop and maintain precise procedures, train relevant employees thoroughly, perform regular audits and updates and keep documentation clear and accessible. Incorporating PESDs can simplify adherence and enhance the effectiveness of these procedures.

Training and communication (491 violations): Insufficient training and updates on safety procedures.

Solution: Enhance and tailor training to specific roles/equipment, regularly communicate procedural/equipment changes and adopt engaging training methods for better retention.

Periodic inspection (362 violations): Failures in conducting regular inspections of LOTO procedures.

Solution: Set up a structured schedule for inspections, allocate necessary resources and integrate these inspections into safety practices for continuous compliance.

Energy control program (265 violations): Absence of a comprehensive energy control program.

Solution: Establish a detailed program with clear procedures, ensure regular training/communication and conduct routine audits, keeping documentation up to date.

Application of control (231 violations): Incorrect application of energy control procedures.

Solution: Enhance documentation and training on LOTO procedures, perform regular drills and monitor real-world application to rectify any discrepancies.

These violations highlight the paramount importance of comprehensive training and rigorous adherence to safety standards. Ensuring that employees are well-versed in energy control procedures is not just a regulatory requirement but a fundamental aspect of maintaining a safe working environment.

Embracing technology for electrical safety

The future of electrical safety also lies in leveraging technology beyond PESDs. From advanced software that helps manage LOTO procedures to mobile apps designed for safety audits, technology can provide additional layers of safety and efficiency. Adoption of such tools can complement the physical safety measures provided by PESDs, offering a more holistic approach to electrical safety management.

While the implementation of NFPA 70E-2024 standards, PESDs and enhanced LOTO procedures poses challenges, such as budget constraints and resistance to change, the benefits far outweigh the hurdles. Proactive engagement, clear communication and demonstrating the value of these safety investments can help overcome obstacles. The continuous evolution of electrical safety standards and technologies promises further advancements in protecting workers from electrical hazards.

The integration of NFPA 70E 2024 updates, PESDs and robust LOTO procedures represents a comprehensive approach to mitigating electrical risks. By embracing these standards and technologies organizations can significantly enhance their safety protocols, protecting a valuable asset — their workforce. As we look to the future, staying informed and adaptable to emerging safety trends and innovations will be key to maintaining a safe and productive workplace.