Sustainability remains a major focus for manufacturers as well as the need for smart digital technologies that can provide better intelligence for companies.

Sustainability insights

- Honeywell emphasized learning from customers to drive future improvements at Honeywell Connect, regardless of industry, showcasing a customer-centric approach to innovation.

- Sustainability is paramount in modern business models as well as aligning with market and societal expectations because it offers long-term cost savings and operational efficiency gains.

The second Honeywell Connect event highlighted many of the same themes from the first show last November: Emphasizing digital transformation to improve operations, intelligence and make workers more efficient and safer. This time, with the show in Dallas rather than Orlando, Honeywell’s emphasis, according to Honeywell Connected Enterprise president and CEO, Kevin Dehoff, is about learning from their customers and using those lessons to improve the future regardless of industry.

This is part of a larger effort by Honeywell as they announced plans to realign its business segments to three trends: Automation, aviation and energy transition. According to a statement released during the event, this shift is intended to deliver accelerated organic sales growth and inorganic capital deployment, creating greater value for shareholders. The new segmentation will take effect beginning the first quarter of 2024.

Sustainability has been a major focus for the last few years due to countries passing legislation to reach net zero on carbon emissions by 2050. Some are going even further and embracing environmental, social and governance (ESG) policies as part of their business model. On top of everything else, it makes good business sense and can save companies a lot of money long-term by being more efficient. While it’s not altruistic, this is where the market and society’s expectations as a whole are going. Much as is the case with the embrace toward automation and the industrial Internet of Things (IIoT) it is a simple matter of joining in and thriving or getting left behind.

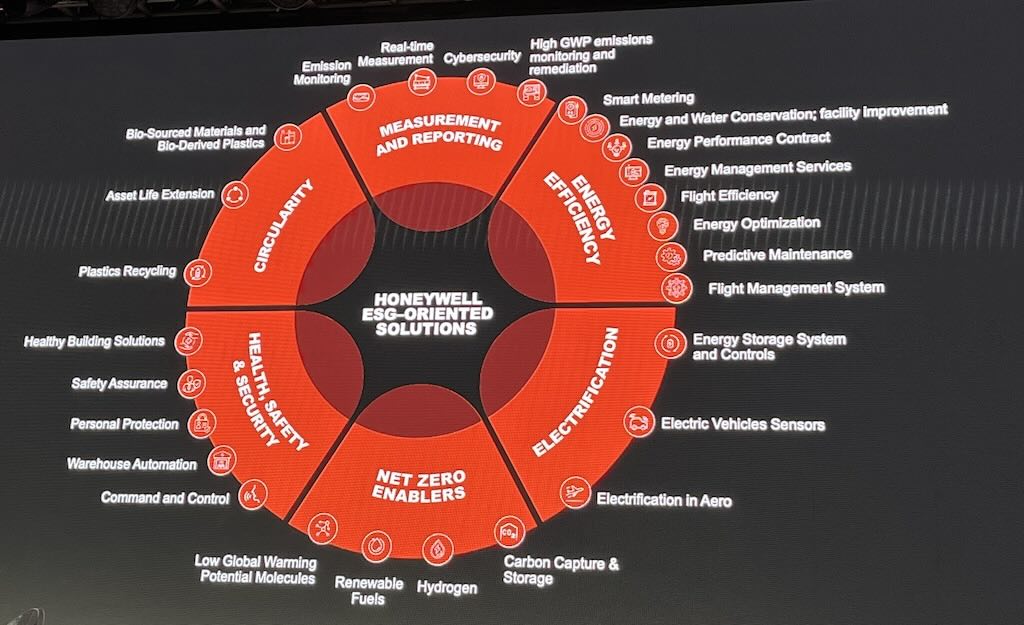

Honeywell emphasized the need for sustainability in process manufacturing at Honeywell Connect last year in Orlando and at Honeywell Users Group (HUG) in June in Orlando. The message remains front and center. They are focused on six areas in particular with their initiatives:

-

Electrification

-

Net-zero enablers

-

Health, safety and security

-

Circularity

-

Energy efficiency

-

Measurement and reporting.

“No matter the industry segment, all our customers are increasingly focused on sustainable operations,” said Honeywell Connected Enterprise and CEO Kevin Dehoff in his keynote presentation.

Honeywell, much as they did last year, are emphasizing digital transformation to improve sustainability and efficiency in their manufacturing operations.

Udaya Shrivastava, VP and CTO for Honeywell Building Technologies, said, “Digitalization and sustainability are connected are part of a transformation journey for any organization. You cannot drive sustainability without digitalization and vice versa.”

Finding and realizing sustainability’s value

While digital transformation is valuable, it is a tool that is only successful if used correctly. In many cases, companies—just as they did with the industrial Internet of Things (IIoT)—leapt before they looked and did not get value. The same is true for digital transformation. It can drive sustainability forward, but it requires a concerted and thorough effort.

“The data is pointing us to deploy advanced technology,” said Anne Madden, senior vice president and general counsel for Honeywell. “Gone are the days of the low-hanging fruit are going to carry the day. They just aren’t. So much more is needed. We need to turn to innovation in software-enabled solutions to measure, optimize, reduce, track and report for better results.”

That’s easier said than done for many companies. Many are playing catch-up and trying to meet these legislative goals as well as their own.

“A lot of companies, when they look at their operations, they’re using a limited data set,” said Dr. Robert Kester, CTO of emissions for Honeywell. “They’re projecting a lot farther out than they need to because they’re using emission factors set years ago. If you collect the data and expose it in a more frequent manner, many of these problems are solvable and low-hanging fruit from an emissions perspective. More frequent checks allow them to solve problems faster.”

He added that companies engaging with the sustainability problem, when they do get access to all the data points, struggle to make sense of it all and determining what is important. Artificial intelligence (AI) and digital transformation tools can help, but it comes down to making the business case in such a way where everyone can get involved.

“Sustainability is important and critical,” said Manish Sharma, VP and chief product office for Honeywell, “but you have to get capital expenditure (CAPEX) and operational expenditure (OPEX) involvement and provide some value because otherwise it’s not going to take.”

More than anything, companies need to act. “Start with the low-hanging fruit and build a roadmap,” said Lucian Boldea, CEO of process materials and technology for Honeywell. “Develop an end-to-end solution be the consultant, provider and enabler. What’s not affordable is inaction.”

Chris Vavra, web content manager, CFE Media and Technology, [email protected].