Industrial organizations benefit from predictive analytics; engineers can use this advice to select the best predictive analytics solution for their operations.

Learning Objectives

- Predictive analytics software should provide troubleshooting capability and a development environment.

- Predictive analytics can help engineers, not only data scientists.

- Trial version of predictive analytics software is available, along with a webcast (for 1 year after July 28) for more information./li>

Industrial organizations know it’s imperative to move ahead at light speed with predictive analytics. However, new analytics startups and consulting companies are showing up weekly. How does an engineer select the best predictive analytics solution for their operations?

The following advice provides guidance for engineers.

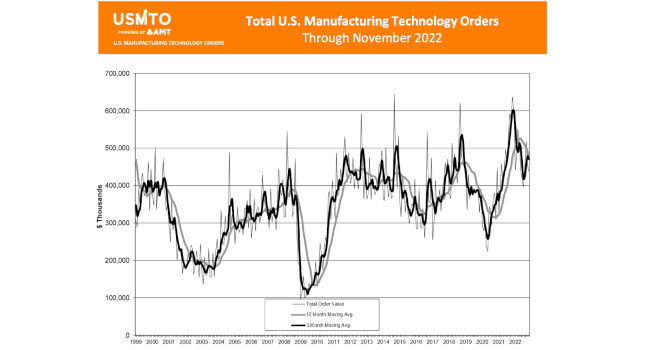

1. Predictive analytics is not just a buzzword

Make sure the term “predictive analytics” isn’t some buzzword hiding behind risky, unproven software and newbie “experts.” For example, GE Digital has offered and implemented analytic software solutions and services for more than 15 years, serving industrial organizations around the world across a diverse set of industries.

Work with a partner you can trust and know will provide long-term support.

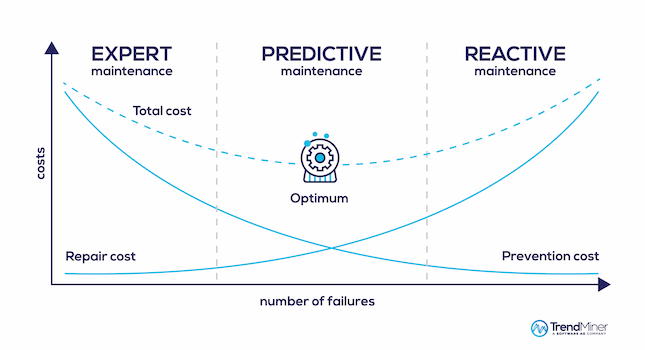

2. Predictive analytics provides troubleshooting capability

Select industrial advanced analytics with a troubleshooting component that enables engineers to rapidly troubleshoot continuous, discrete or batch manufacturing process performance by mining insight from available manufacturing sensor and production data.

Seamless connectivity, rich visualization and predictive analytics enable engineers to analyze operating scenarios, quantifying the impact that operational changes will have on key performance metrics and identifying causes for performance variation.

To fully support the Internet of Things (IoT) value journey, look for capabilities from simple calculations to predictive machine-learning models to real-time optimization and advanced-control algorithms.

3. Development environment enables predictive analytics

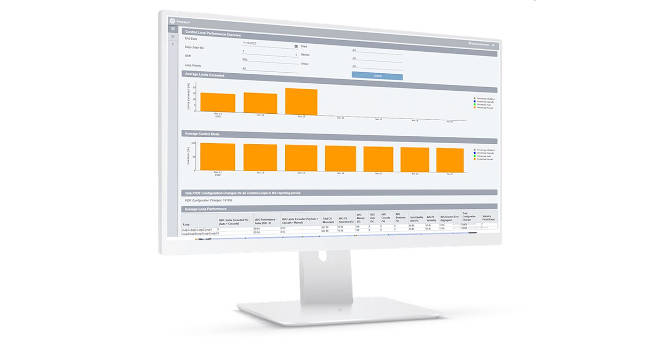

Be sure the analytics package enables engineers to develop analytic solutions – supporting improvements in production throughput, yield, quality and efficiency with significant margins.

A comprehensive analytic solution-development environment provides visual analytic building blocks to build and test calculations, provide predictive analytics and deliver real-time optimization and control solutions with connectivity to real-time and historical data sources and drag-and-drop access to rich functional libraries.

Plug-and-play connectivity to historical and real-time data sources and automation systems make for faster configuration. Built-in support for data quality makes real-time data cleaning and validation easy.

4. Predictive analytics templates for rapid development

Confirm that the analytics package can speed deployment with templates for greater efficiency.

Engineers should be able to save analytics solutions as reusable templates for easy deployment to similar assets or process units. While the analytics troubleshooting component should enable engineers to find answers faster with analytics-guided data mining and process-performance troubleshooting, the development/configuration capabilities should allow engineers to capture expert knowledge and best practices into high-value analytic templates for rapid enterprise-wide deployment.

5. Predictive analytics can focus on engineers, not just data scientists

Focus on analytics solutions developed with engineers – not just data scientists – in mind.

With an analytics package that is accessible to engineers, teams can create a process digital twin for smarter operations.

Visual drag-and-drop analytics accelerate time to value and reduce dependence on data scientists and programmers. Online demos enable rapid mastery of the software with easy-to-follow demonstrations and guided simulations.

A rapid development environment is critical. The best solutions provide wizard-driven data mining for engineers for fast time-to-insight, an easy visual drag-and-drop environment for subject matter experts and engineers, and analytic solution templates without programming for simple calculations, data cleaning, math, statistics, machine-learning models, real-time optimization and advanced process control (APC).

Get started: Ready to try a predictive analytics solution that meets all of the key requirements? Get a free trial of GE Digital Proficy CSense and explore and explore how you can optimize your operations.

Webcast: Fueling advanced analytics with industrial data management

GE Digital provided this information to Control Engineering in conjunction with the July 28 webcast, “Fueling advanced analytics with industrial data management,” presented by Steve Pavlosky, principal product manager, GE Digital’s Proficy Historian and Data at the Edge.

Alicia Bowers Millinger is senior product marketing manager, GE Digital. Edited by Mark T. Hoske, content manager, Control Engineering, CFE Media and Technology, [email protected].

KEYWORDS: Predictive analytics, industrial analytics

CONSIDER THIS

Putting predictive analytics software into the hands of plant-floor engineers can optimize operations.