Advanced early detection enabled by Artificial Intelligence of Things (AIoT) enhances emissions monitoring by ensuring real-time data accuracy and quick issue resolution, improving environmental compliance and operational efficiency.

Learning Objectives

- Understand why continuous fenceline monitoring is essential for meeting the EPA’s new HON requirements and how it helps control hazardous air pollutants (HAPs) and volatile organic compounds (VOCs).

- Explore advanced technologies for emissions monitoring.

- Identify and understand the role of advanced technologies like IoT sensors, gas chromatographs and optical gas imaging cameras in accurate leak detection and emissions control within chemical process industries

HON requirements insights

- The Environmental Protection Agency (EPA) has new rules that will have a significant impact on the chemical process industries.

- Fenceline monitoring to measure these pollutants will now be required for industrial facilities to ensure compliance with environmental regulations.

The Environmental Protection Agency’s (EPA) new, stricter rules are set to transform operations within the chemical process industries. These regulations encompass a wide range of volatile organic compounds (VOCs) and hazardous air pollutants (HAPs), including ethylene oxide, chloroprene, benzene, 1,3-butadiene, ethylene dichloride and vinyl chloride, all of which can pose health and environmental risks if not properly managed.

To comply with these new rules, chemical manufacturers must regularly report emissions levels, control methods and compliance statuses. Routine inspections for equipment leaks are mandatory, with prompt repairs required. Advanced technologies like internet of things (IoT) sensors, gas chromatographs and optical gas imaging cameras may be necessary to accurately detect leaks. The good news is that chemical process industries have a phase-in period in which to upgrade equipment, train employees and implement new procedures, with clear compliance deadlines.

Impact of HON on the Clean Air Act

The Clean Air Act from the EPA protects public health and the environment by setting air quality standards and limiting emissions of HAPs. The EPA’s Hazardous Organic NESHAP (HON) rule requires that chemical manufacturers control HAP emissions through pollution control equipment, specific work practices, regular monitoring and meticulous recordkeeping, reporting and performance testing.

Key examples of hazardous emissions sources (see Figure 1) include:

- Medical sterilization units: ethylene oxide

- Rubber manufacturing units: chloroprene

- Oil refineries: benzene

- Plastic production units: 1,3-butadiene

- Polyvinyl chloride manufacturing plants: ethylene dichloride and vinyl chloride

Understanding and mitigating these emissions is key for environmental compliance and public health. The HON rule plays a significant role in minimizing these emissions, improving air quality and ensuring public safety, necessitating important operational and economic adjustments within the industry.

Fenceline monitoring based on sampling methods

Fenceline monitoring to measure these pollutants will now be required for industrial facilities to ensure compliance with environmental regulations. The goal is to assess air quality at property boundaries. The EPA provides specific guidelines and methods for effective fenceline monitoring, primarily focusing on VOCs and HAPs. Two primary EPA methods, 325A and 325B, are employed for this purpose.

Method 325A outlines procedures for deploying passive samplers around a facility’s perimeter to monitor VOCs. Key aspects include site selection, sampler installation and exposure duration. Appropriately locating passive samplers is critical; they should be placed in areas representative of the facility’s emissions, considering factors such as wind direction, proximity to emission sources and potential impact zones. Proper installation ensures effective monitoring, typically mounting the samplers on poles or other structures at specified heights to maximize exposure to ambient air. The exposure duration varies based on monitoring objectives, but samplers are generally deployed for periods ranging from 14 to 30 days prior to removal and analysis.

On the other hand, Method 325B provides detailed guidelines for analyzing VOCs collected by passive samplers. The analytical process includes the extraction of pollutants, quantification using gas chromatography and data interpretation.

Here’s how it works: once the exposure period is complete, the passive samplers are retrieved and the absorbed pollutants are extracted from the sorbent material The extracted pollutants are analyzed using gas chromatography, a precise and reliable method for quantifying VOC concentrations, providing detailed insights into the types and levels of pollutants present.

Finally, the data obtained from the analysis is interpreted to assess compliance with regulatory standards, allowing facilities to identify trends, pinpoint emission sources and implement necessary corrective actions.

Transforming sampling methods for HON requirements: a strategic opportunity

The current sampling methods offer various challenges and provide significant opportunities to enhance a facility’s ability to comply with the new HON requirements:

- Accelerating data availability: Leveraging “add-on,” advanced technologies can dramatically reduce data collection and analysis times, enabling quicker identification and resolution of emission issues.

- Enhancing temporal resolution: Innovative sampling methods to supplement the EPA’s methods can deliver more granular data, capturing short-term emission spikes and providing a clearer, more accurate picture of environmental conditions. Strategic placement of samplers further enhances data accuracy and representativeness.

- Maximizing financial and operational efficiency: Investing in state-of-the-art, real-time analysis and automated data processing tools can lower maintenance costs over time, as effective identification and correction of issues can allow for “skip” period monitoring using the EPA Methods. Automation will streamline data reporting, minimizing manual errors and operational burdens.

- Integrating cutting-edge monitoring techniques: Incorporating continuous emissions monitoring systems and real-time sensors to enhance the EPA required monitoring can drive comprehensive and effective compliance, harnessing the strengths of diverse methods to create a robust monitoring framework.

These strategic opportunities set the stage for a more effective and efficient approach to meeting HON requirements, ensuring environmental compliance and driving operational excellence.

Early detection power: identify quickly, fix fast in emissions monitoring

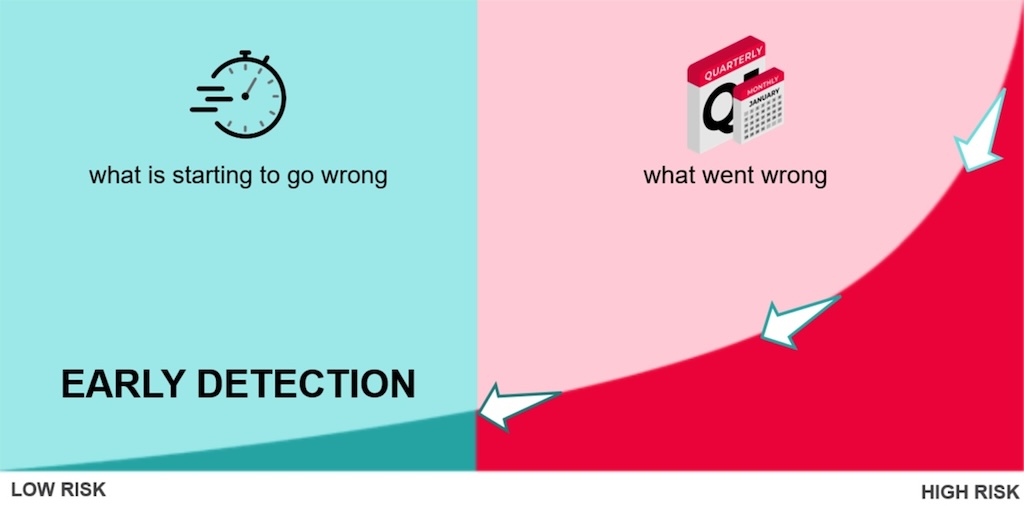

Implementing early detection systems for HON fenceline monitoring offers a myriad of advantages that significantly enhance both environmental compliance and operational efficiency. By integrating advanced technologies into monitoring practices, facilities can achieve a higher level of oversight and control over their emissions. Early detection provides real-time emission data, allowing for quicker identification of issues and enabling timely responses to mitigate potential risks by focusing on what is starting to go wrong (see Figure 2).

The ability to receive instant alerts about emission spikes empowers operators to take prompt corrective actions, ensuring that potential compliance issues can be addressed before they escalate. Continuous data analysis generates valuable insights and trend analyses, aiding in the development of effective mitigation strategies that are data-driven and precise.

Moreover, enhanced detection capabilities with artificial intelligence of things (AIoT) leverage high-fidelity sensors and AI/ML-based analytics to provide accurate, continuous monitoring of emissions, covering multiple pollutants comprehensively. These technologies not only improve the accuracy of monitoring but also extend the range and depth of pollutant detection, ensuring comprehensive environmental protection. Early detection systems are also cost-effective, as they reduce long-term compliance costs by providing real-time insight into potential events causing impacts at the fenceline, allowing early identification and correction, prior to exceeding a threshold. If a threshold exceedance were to occur, the real-time data, including wind direction, will aid in identifying sources of emissions — whether onsite or nearfield (i.e., adjacent off-site sources) — significantly expediting and improving the accuracy of any required investigations and corrective action plans. Adopting early detection, real-time systems for HON fenceline monitoring is a crucial step toward achieving sustainable and efficient industrial operations and compliance.

Early detection enhances sampling: a feasible path to immediate impact

Early detection for fenceline emissions can significantly address anomalies more effectively compared to traditional sampling methods. Leveraging cutting-edge technologies such as AIoT, real-time monitoring delivers immediate and precise data on various pollutants. These advanced systems empower instant detection of emission anomalies, enabling swift and decisive actions. Unlike periodic sampling, which might miss transient events, real-time monitoring supports continuous data accuracy and a more accurate reflection of current conditions.

The integration of early detection with traditional sampling methods creates a symbiotic relationship that enhances overall emission monitoring. Real-time detection can precisely identify when and where additional investigatory steps should be taken, leading to more targeted and effective investigations of anomalies. Furthermore, the detection of anomalies in real-time can automatically trigger an increase in focused investigation in affected areas, ensuring that significant emission sources, including intermittent activities, are not overlooked.

In essence, early detection technologies provide real-time data that seamlessly complements traditional sampling methods, enabling more accurate and timely responses to emission anomalies. This powerful integration ensures a robust and responsive emission management strategy, mitigating potential risks and bolstering regulatory compliance.

Early success in fenceline monitoring for HON compliance at a chemical plant

A leading U.S. chemical plant has significantly advanced its fenceline monitoring management strategy by deploying an AIoT-enabled solution for the early detection of fenceline emissions of 1,3-Butadiene. This initiative aligns with HON standards, which require stringent control of HAPS to protect both the environment and public health.

Utilizing the early detection approach, the plant continuously gathers data on various pollutants, with a particular focus on VOCs like 1,3-Butadiene. The solution installed at the plant’s fenceline detected a sudden and unexpected spike in 1,3-Butadiene levels. The real-time insights (see Figure 3) quickly identified the anomaly as significant and unusual compared to the baseline emission patterns.

When the solution detected an anomaly, it instantly triggered an automated alert to the plant’s environmental management team. The alert provided detailed information about the spike, including its magnitude and exact location. This real-time notification enabled the team to mobilize immediately and respond swiftly. Leveraging precise real-time data, they pinpointed the exact area of the intermittent spikes for verification and further investigation.

This targeted approach eliminated the guesswork typically involved in traditional periodic sampling, making the investigation more efficient and effective. Analysis revealed the anomalies are due to an external factor near the fenceline, but outside the plant boundaries (i.e., a near-field source). Armed with these insights, the environmental team was able to document the offsite nature of the source. The additional information provided by the sensors significantly aided in the investigation of the anomalies, expediting the closure of the investigation.

Further, this technology is preparing the site for compliance with the HON standards by providing insights now, before the fenceline monitoring requirement goes into effect, regarding potential emission sources both on and off-site, which in the long term will prevent potential regulatory violations and fines and ensure compliance with HON standards. The prompt resolution also allowed the plant’s operations to continue uninterrupted, maintaining productivity and safety standards.

This case exemplifies how early detection can transform emission monitoring and management in industrial settings. By leveraging real-time data and advanced analytics, the chemical plant was able to detect, respond to and address anomalies effectively. The result was a robust and responsive emission management strategy, enhancing regulatory compliance, environmental stewardship, and operational efficiency. This proactive approach underscores the value of early detection technologies in modern industrial operations, ensuring sustainable and responsible environmental practices in line with HON requirements.

Unlocking potential: early detection for seamless HON compliance

The EPA’s new and stricter HON rules aim to reduce harmful pollutants in the chemical process industries and early detection technologies are crucial in meeting these HON requirements. By integrating advanced technologies such as AIoT for early emission detection, chemical manufacturers can achieve real-time monitoring that provides immediate and precise data on various pollutants. This allows for the instant identification of emission anomalies, enabling swift and decisive actions to mitigate potential risks. Unlike traditional periodic sampling, real-time monitoring ensures continuous data accuracy and a true reflection of current conditions.

Implementing early detection systems offers several advantages, including providing instant alerts on emission spikes, empowering operators to take prompt corrective actions. Continuous data analysis generates valuable insights, aiding in the development of effective, data-driven mitigation strategies. Enhanced detection capabilities with AIoT-based analytics also improve both environmental compliance and operational efficiency. These systems are cost-effective, reducing long-term operational costs by preventing unplanned downtime and optimizing maintenance schedules.

Early detection technologies provide a robust and responsive emission management strategy that significantly enhances regulatory compliance, environmental stewardship, and operational efficiency. This transformative approach underscores the crucial role of early detection in modern industrial operations, ensuring sustainable and responsible environmental practices in alignment with HON requirements.