Battle of the backup: Evaluating a 1 MW solar PV/natural gas microgrid for firm on-peak power and resiliency

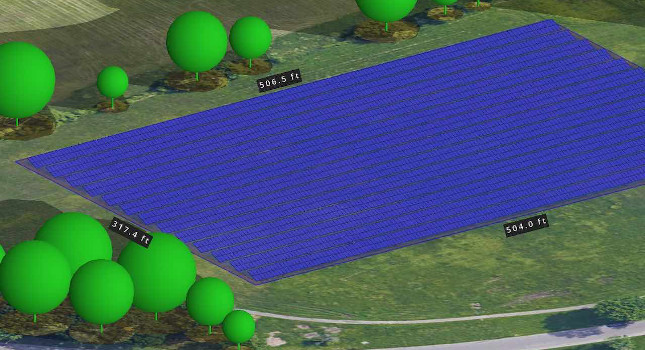

Microgrids using multiple sources of generation have the potential to add resiliency to both the grid and to customer sites. Additionally, if low carbon sources of electrical generation are used such as solar photovoltaics (PV), these microgrids can significantly reduce the energy carbon footprint (see Figure 1). However, the solar resource is variable and intermittent, requiring that other sources of generation, or energy storage, are used for a complete and resilient design. This article describes the results of a study of a 1 MW solar PV microgrid model, hypothetically located at a large Michigan commercial facility. The simulated annual PV output is connected on the customer side of the power meter, and the cost savings is analyzed against a the large commercial, DTE Electric, time-of-day primary service rate. A popular solar PV simulation software tool, Helioscope, was used to model the hourly PV output against the customer electric interval data for one year, to present both operational cost savings and performance of seven generation configurations:

- 0 MW dc to 1.0 MW ac solar PV array

- 3 MW dc to 1.0 MW ac solar PV array

- 0 MW natural gas generator only (no solar PV)

- 0 MW dc to 1.0 MW ac solar PV array plus natural gas generator

- 0 MW dc to 1.0 MW ac solar PV array plus 1.0 MW/8 MWh Li-ion battery

- 3 MW dc to 1.0 MW ac solar PV array plus natural gas generator

- 3 MW dc to 1.0 MW ac solar PV array plus 1.0 MW/8 MWh Li-ion battery.

Working with real pricing provided by engine generator and battery OEMs, the capital cost, fuel usage, maintenance, 20-year lifecycle cost and carbon savings were compared for all variations as needed to produce a firm eight hours of “on-peak” power for the customer. The results demonstrate the value and potential of hybrid microgrid systems, as well as the limitations of large Li-ion batteries as compared to a natural gas generator.

Details of the study

To provide eight hours of firm on-peak power with a solar PV array, the firming power must be capable of operating at the full 1 MW capacity for eight hours during cloudy days. This can be accomplished by a 1 MW/8 MWh battery or a 1 MW gas generator. The 8 MWh designation is the size of the battery cell storage, while the battery inverter would only be sized to the 1 MW power requirement. The on-peak hours for DTE Electric include the hours between 11 a.m. to 7 p.m., Monday through Friday, minus 10 holidays each year, and all kilowatt demand-based charges for the monthly billing and the annual kilowatt demand peak, or “ratchet” are based on a maximum kilowatt seen in a 30-minute rolling window during on-peak hours. Additional cost savings are achieved from a 1 MW demand reduction, often called “peak shaving.” Alone, solar PV can capture some fraction of this demand savings, but with the intermittent nature of solar energy, it is often one quarter to one third of the total possible demand savings, which is 1 MW for this study.

While cost savings are based on the DTE electric rate and a customer natural gas cost of $3.50 per million BTU, the carbon savings are generated using the Michigan electric grid for year 2020, and the estimated carbon content for year 2050. The study uses carbon data are taken from recent work by the consulting firm ICF International using USEPA eGrid Power Profiler 2018 data for the Michigan region labeled RFCM, as commissioned by the Energy Solutions Center. ICF estimated eGrid region carbon content in year 2020 and 2050 using its “Integrated Planning Model,” which considers regional legislation, mandates, utility commitments and announced power generation mix from the region.

The USEPA graphic illustrates the eGrid regions, and the carbon intensity varies across the map (see Figure 2). The Midwest U.S. still contains a fair amount of coal-fired generation, yielding a 2018 eGrid RFCM (Michigan) carbon intensity of 1.66 lb CO2 per kWh. (0.75 kg CO2 per MWh). ICF estimates that in the year 2050, this RFCM region will still produce 0.989 lb CO2 per MWh (0.45 kg CO2 per MWh). There is no CO2 attributed to the solar PV output, and the gas generator is assumed to have an average 33% electrical efficiency and is fueled by natural gas producing 117 lb CO2 per million BTU (181.5 kg per MWh) consumed.

For the solar PV portion, zero carbon is attributed to its kilowatt-hour production, and for the natural gas generator, DTE Energy assumed a generic, 33% electrically efficient unit, with natural gas combustion producing 117 lb/MMBTU (181.5 kg/MWh).

The firming output power is controlled to provide a 1.0 MW microgrid net power output during all on-peak hours. Figure 3 shows a five-day simulated period during a higher solar resource timeframe in August. The red line illustrates the solar PV array output firmed up by the dashed blue line of firming power kilowatts. The combined output yields the bold black line showing 1.0 MW of microgrid output during all on-peak hours needed to obtain the kilowatt demand cost savings. The functionality of this system also would provide 1.0 MW of backup power to the host customer site. The battery system will be limited to eight hours, while the gas generator would provide a continuous backup for as long as needed.

Figure 3: Solar PV power output plus firming generation for five summer days. Courtesy: DTE Energy, James Leidel[/caption]

CO2 reduction and cost estimates

Carbon savings are illustrated in Figure 4 for both 2020 and 2050. Each microgrid system achieves a CO2 reduction in 2020, with the largest being the 1.3 MW dc solar plus gas generator (recall that the battery is grid-charged at night). In the year 2050, this is no longer the case, and the gas generator now produces more CO2 than the grid. However, by this time it is likely that carbon capture from the engine exhaust or cost-effective renewable gas fuels also will lower the CO2 footprint of this same gas generator. Renewable biogas-derived methane, and Power-to-Gas-derived renewable hydrogen are seeing significant attention and investments today, so, by 2050, they will likely become cost competitive.

Lastly, we investigate the capital cost per ton of CO2 reduction. Decisions are most often made with financial considerations as a primary. The maximum reduction in CO2 and the fastest method to accomplish this goal also is worthy of consideration, as well as potential future technologies and expected future grid carbon intensities.

Figure 5 illustrates the capital cost per ton CO2 reduced in relation to the Michigan RFCM grid. The lowest cost per ton reduced is the 1.3 MW dc solar only option. However, this system is intermittent and only provides kilowatt-hour support, but not the required firm 1 MW power demand. The best performer for firm demand reduction is the 1.0 MW dc solar plus gas generator. This system also has the fastest financial payback at 6.8 years of any of the firm power solar PV options. The best payback is the gas generator only option. This is largely supported by the low natural gas fuel price of $3.50/MMBTU ($3.32/GJ natural gas). The significantly higher unit cost of CO2 reduction for both PV plus battery systems is due in part to the need to charge the batteries at night from off-peak grid energy and the 2020 capital cost of the 1 MW/8 MWh Li-ion battery. In future years, the grid CO2 intensity will fall, as will the capital cost of utility scale Li-ion batteries. However, consider that the CO2 intensity of the gas generator fuel supply will also fall in future years as economically priced renewable gases are introduced into the gas distribution grid as well.

Looking ahead

Solar PV plus natural gas generation is an effective and economical microgrid solution for both cost and carbon performance. This will be true for decades into the future in the Midwest U.S. Renewable gases such as renewable methane and hydrogen can make the Solar PV plus gas generator microgrid 100% net zero carbon as these fuels become more economical. Other eGrid regions will perform differently than the Michigan RFCM eGrid region, but the PV simulation and microgrid model presented here could be easily replicated for any location in the U.S.

– This article appeared in the Gas Technology supplement.

Acknowledgments

- Kevin O’Connell of Michigan Caterpillar supplied capital equipment and maintenance cost estimates for a natural gas generator and Li-ion battery system.

- Caleb Patrick of Tesla Energy supplied information on large utility scale Megapak battery budgetary pricing and data.

- Eric Burgess of the Energy Solutions Center provided grid carbon intensity estimates for 2020 and 2050, via a study commissioned from ICF International (www.icf.com).

MORE info

DTE Energy

U.S. ENVIRONMENTAL PROTECTION AGENCY EGRID POWER PROFILER