Combined heat and power (CHP), distributed generation (DG), and microgrids keep university campuses energized—fueled by natural gas.

Combined heat and power (CHP) systems generate electricity and usable thermal energy from onsite generator sets. Typically, CHP systems are used at facilities with high heat load requirements, such as universities/colleges, hospitals, and industrial campuses.

A microgrid is a localized electrical network that allows campuses and other similar-sized districts to generate and store power from various distributed energy resources including renewables. Microgrid usually refers to a collection of two or more distributed generation assets working together to serve a common load center, such as critical facilities, hospitals, colleges, or small communities, and can be isolated from the larger grid and still provide electricity.

Distributed generation (DG) typically refers to a category of equipment used to generate electricity, such as CHP, solar panels, battery or energy storage, generator sets, or fuel cells at or near the end user. DG equipment is distributed either on the user’s side of the meter or located near utility distribution lines.

CHP, DG, and microgrids are related

“CHP is a central component to most microgrids,” said Doug Edgar, vice president of operations at White Harvest Energy, a distributor for 2G Energy. “For example, if the microgrid consists of only solar panels and battery storage, it could become useless at night or a cloudy day when the battery has been exhausted. CHP provides on-call, reliable energy, and is typically a work-horse ensuring the supply and demand of electricity is equal.”

“CHP is an effective resource that should be part of the local microgrid,” said Chris Lyons, manager, power generation at Solar Turbines. “In most cases, this would be an ideal anchor for the microgrid because it can use a host of fuel supplies with the most reliable, and easiest to use being natural gas. CHP plants also can use the energy outputs to provide thermal storage of chilled water and even heat to provide better overall security of energy supply to the microgrid.”

The case for natural gas

Microgrids almost always include one or more gas turbines, reciprocating engines, or steam turbines that can produce a controlled amount of power. The energy source for these is usually natural gas.

Traditionally, diesel engine-generator sets have been installed as standby generation in health care centers, universities, government facilities, and other mission critical campuses because they are able to pick up critical elements of the electrical load if the utility power goes down. In addition, diesel engines start quickly and, if properly maintained and periodically tested, provide reliable backup power. However, they require onsite fuel storage for two or more days of operation, and that fuel has to be kept in good condition. Because of emission restrictions, unless they have significant upgrades for pollution control, they cannot be operated other than in emergency service.

While there are increasing limitations on diesel, natural gas is becoming a viable alternative fuel. “In the U.S., natural gas is a very cost effective and reliable source of fuel supply for microgrids and/or DG,” Lyons said. “However, this is not the same across the globe where there are still places without natural gas distribution and in some cases due to limited or constrained supplies, can be very expensive. In these cases, alternative fuel supplies would be a better choice.”

“Natural gas is very reliable in terms of infrastructure and availability, which makes it a great choice for microgrids and/or DG,” Edgar agreed. “However, in some areas of the country—the Northeast in particular—natural gas supply may become scarce or costly during really cold snaps or winter storms and may be subject to curtailments.”

Generator sets versus gas turbines

Using generator sets or gas turbines for CHP, DG, and microgrids does not have to be mutually exclusive. When asking the question, “Which technology is ideal for CHP, DG, and microgrids?” The answer is, “It depends on the specific application.”

Both natural-gas powered generator sets-such as the CHP microgrid system installed at Texas Wesleyan University—and gas turbines—such as the ones installed in the CHP plant at Cornell University-have their applications. “Gas turbines have high grade exhaust heat that can be used to make steam, chilled water, or for various drying applications including processes, such as tissue production and ceramic tile,” Lyons said. “Gas turbines have very fast response times and provide excellent localized VAR (reactive power) support. Internal combustion engines use lower gas supply pressures and are more electrically efficient in open cycle than gas turbines. Each technology has its applications, but in many cases, work well in combination.”

“Gas turbines supply more thermal energy than reciprocating internal combustion engines,” Edgar said. “However, they require natural gas compression equipment if the NG pressure is not adequate. This adds more capital cost and another maintenance item. Internal combustion engines have better turndown than gas turbines, meaning, they can run at 40% or 50% fairly easily and without excessive efficiency loss. Gas turbines will take a larger hit to efficiency or will not even run at low loads. Gas turbines also are more susceptible to ambient conditions than internal combustion engines. At high ambient temperatures or high altitude (both create lower air density), gas turbines have a larger reduction in efficiency and output than internal combustion engines.”

Why universities are choosing CHP, DG, and microgrids

Microgrids are owned and operated by college and university campuses, military bases, hospitals, housing complexes, research facilities, and some municipalities and businesses. Typically, these are organizations that place a high value on energy reliability, efficiency, security, power quality, or minimized environmental impact.

“Having one large distribution network of various buildings, living spaces, and research facilities all located on a contiguous property make universities and military bases ideal candidates,” said Lyons. “Municipalities that can control the integration and distribution of energy supply to various buildings and users also is an excellent application.”

According to Lyons, there are two main drivers to implementing a microgrid. “The first is reliability of the energy supply to avoid issues if the main grid is out for a host of supply issues including cybersecurity, weather related reasons, or even grid congestion causing potential supply interruptions. The second is the ability to integrate the variety of potential generation assets, both for cost and for environmental improvements,” he said.

“Microgrids place the generation of electricity locally and decreases the amount of risk associated with a faulty, failing, or disrupted grid,” said Edgar. “The typical example is a severe storm that knocks out a main transmission line, which affects several neighborhoods or an area of downtown. With a microgrid, power is local (there are little to no transmission lines) or power is re-allocated to serve the critical loads as needed.”

Microgrids could reduce utility costs, according to Edgar. “CHP is a more efficient means of producing energy, which equates directly to utility savings. Solar and wind offer tax credits and other benefits,” he said.

Lyons suggests that CHP, DG, and microgrids are not a panacea. “CHP only makes sense when you have the proper balance of power and thermal demands,” he said. “It is not a solution for areas that do not have critical loads that do not need to operate independently of the grid or where various generation assets cannot be economically controlled.”

Cornell University launches CHP

To improve efficiency and reduce emissions, Cornell University replaced coal-fired boilers in 2009 with two Solar 15 MWe Titan 130 gas turbine generator sets for its CHP plant. Previously, the Ithaca, N.Y. campus purchased 80% of its electricity from the local utility. The turbines now fulfill 80% of the campus power and steam needs to 150 buildings covering more than 14 million sq ft. By early 2011, the university discontinued use of coal as a fuel source. Cornell’s district energy systems produce hot water, steam, or chilled water at a central plant and then distributes them through underground pipes to buildings connected to the system. Cornell students, faculty and staff use hot or chilled water to meet their space heating, water heating, processing, and air-conditioning needs. After water is used, it is returned to the central plant to be reheated and rechilled before recirculating through the closed-loop piping system.

“The natural gas fired project at Cornell University was installed to meet growing steam demands, provide onsite distributed generation after concerns over the August 2003 Northeast blackout, and to replace older coal fired boilers that would have been subject to new environmental regulations such as Boiler MACT,” said Lyons. “This allowed Cornell to significantly reduce its greenhouse gas (GHG) emissions and upgrade its district energy plant with more reliable and lower-polluting natural gas-fired combustion turbines. The plant uses duct firing of the turbine’s exhaust heat to meet peak winter steam demands for heating and when this demand is lower in the summer, can use the steam in combined cycle with the steam turbine for good overall efficiency. A load management system was developed to include import/export control, main-tie-main automation of the secondary bus at the primary substation, load shedding and bump-less transfer to island mode operation, and synchronization across the mains and ties at the primary substation.”

Texas Wesleyan University chooses CHP

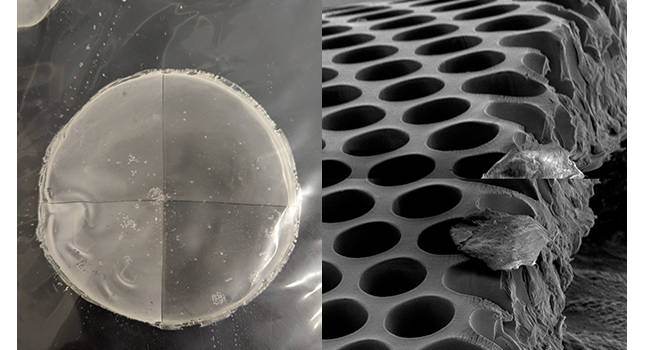

Texas Wesleyan University in Fort Worth, Texas, launched an energy-saving project in 2015. The centerpiece of the project is 2G Energy’s avus 800, a natural gas-powered CHP plant that supplies 80% of the power to the 83-acre campus, while reducing the university’s dependency on the public power grid. The power plant also includes a 250-ton absorption chiller, new cooling tower, new heating boilers, pumping systems and central plant optimization controls. The system has been in operation since 2016.

According to Edgar, the CHP system generates electrical energy used directly by the university’s multiple facilities. “Hot water is generated from the combustion exhaust gases as well as engine cooling circuit. This hot water is sent next door to the university’s energy plant where it is either delivered to facilities as hot water for heating in the winter or sent to an absorption chiller where it is turned into chilled water for cooling in the summer,” he said.

The 2G Energy avus 800 CHP system is equipped with exhaust gas heat recovery heat exchangers and fan coolers (i.e., radiators) to reject heat to the atmosphere when the CHP system generates too much heat during shoulder months. The first priority is to use the heat in the university, but it must go somewhere to keep the engine-generators cool and running smoothly, according to Edgar.

Many projects have their challenges and this one is no exception. “The CHP is not allowed to export power and must import a minimum amount of electricity,” said Edgar. “Therefore, it is critical that the CHP system and grid communicate via controls and relays to ensure good power quality for the university and the surrounding neighborhoods. This required close coordination and communication with the local utility.”

DG, CHP, and microgrid perks

CHP systems can reduce operating costs, increase electrical reliability, and reduce greenhouse gases. A microgrid can operate as an “island” or independently from the larger utility grid as required. Advantages include lower heat and power costs (using CHP) compared to a centralized utility company, lower carbon footprint, minimized impact of weather emergencies, higher security, and higher power quality. Having electrical power generation capability on the user site of the meter (DG) definitely has its perks.

2G Energy

Energy Solutions Center

https://understandingchp.com/installations/case-studies/

Solar Turbines

www.solarturbines.com

This article originally appeared in the Gas Technology Summer 2018 issue.