The 2020 Plant Engineering electrical safety survey examines how your plants’ electrical safety programs measure up

What stands out in the 2020 Plant Engineering electrical safety survey is nine in 10 facilities have an electrical safety program that heightens the overall awareness of potential electrical hazards and self-discipline on the plant floor. Results of these programs indicate electrical safety awareness has an impact, as 97% of respondents believe their employees feel safe on the job, and 80% said employees feel respected by management. Also, 80% of respondents have observed an increase in productivity over time due to implemented electrical safety programs.

Click here to view the digital edition for additional charts from the survey about electrical safety effectiveness on the plant floor.

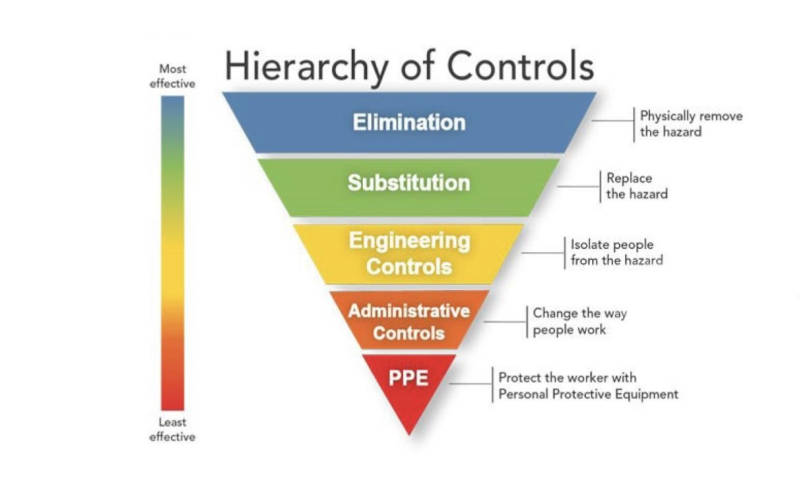

When it comes to where electrical safety programs excel, 75% of respondents say their facilities do well at placing emphasis on personal protective equipment (PPE). However, the surprise is the gap between this and the next response: Emphasis on electrical safety training at 53% — a 22% difference. Another surprise is only 42% of respondents said their facility’s electrical safety programs excel at placing emphasis on arc flash.

Enforcing electrical safety

According to survey respondents, the top seven methods plants use to enforce electrical safety are job safety analysis (79%); regular safety meetings (72%); safety audits (68%); discipline, suspension or termination (67%); management leadership (63%); safety committee (63%); and peer-to-peer (57%).

Although the largest number of respondents (35%) said electrical safety meetings are held only as needed and at undefined intervals, those who contribute advice or input at these meetings are no surprise. The top five players include electrical department management/supervision (60%), electricians (58%), engineering (57%), safety executives/managers (56%) and maintenance (55%).

Electrical incidents

In the 6 months prior to this survey, 66% of respondents had zero OSHA recordable electrical incidents in their facilities. In the same timeframe, 69% of respondents had zero OSHA recordable electrical incidents resulting in lost time.

Courtesy: CFE Media and Technology[/caption]

Study highlights

- Highlights of the 2020 Plant Engineering electrical safety study include the following:

- Respondents have worked in plant- or engineering-related positions for an average of 27 years.

- Safety meetings are the primary method of informing electrical workers and management about electrical-safety-related issues or incidents.

- Respondents are located throughout the U.S., and especially in the, east north central, south Atlantic and Pacific regions.

- 68% of respondents are responsible for maintaining, implementing or managing electrical safety standards.

- 63%of respondents are impacted by electrical safety standards in their day-to-day work operations.

- The annual cost of electrical safety training per employee is $845.

- The average annual budget for electrical safety training and equipment is $33,910.

- 42% of respondents made no change to the budget for electrical safety training and equipment from 2018 to 2019; only 23% increased budgets.

- 93% of respondents indicate the company pays for a worker’s electrical safety equipment and personal protective equipment (PPE).

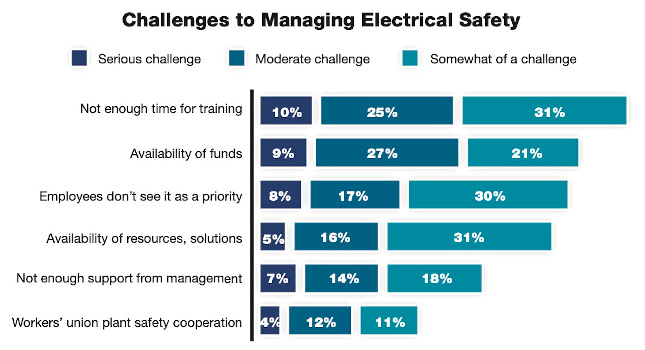

- Not enough time for training is the primary challenge to electrical safety, according to 66% of respondents.

- 48% of respondents say their companies excel at placing emphasis on PPE.

ONLINE extra

Click here to view the May digital edition and see additional charts from the survey.