Plant and manufacturing engineers can pursue sustainability through innovative technologies and energy efficiency practices.

Learning objectives

- Identify the key technologies — such as electrification, automation and predictive maintenance — that support sustainability and emissions reduction in industrial operations.

- Evaluate the business benefits of implementing sustainability strategies, including improved efficiency, regulatory compliance and reduced total cost of ownership.

- Recognize the importance of net-zero targets in manufacturing, such as reducing greenhouse gas emissions across operations and value chain.

- Sustainability is now a core business driver as industries confront climate challenges by electrifying operations, automating systems and optimizing energy use to reduce emissions and boost efficiency.

- Manufacturers that prioritize sustainability not only lower their environmental impact but also unlock long-term profitability, resilience and competitive advantage in a low-carbon economy.

With climate concerns becoming increasingly urgent, reducing emissions in industrial operations has become a business imperative. The industrial sector accounts for nearly 30% of global CO₂ emissions, making it essential in the push toward net-zero.

This presents a challenge and opportunity for plant managers and engineers: how to drive operational efficiency while cutting carbon and staying competitive in a rapidly evolving industry. Companies with strong sustainability programs tend to achieve higher profitability than competitors.

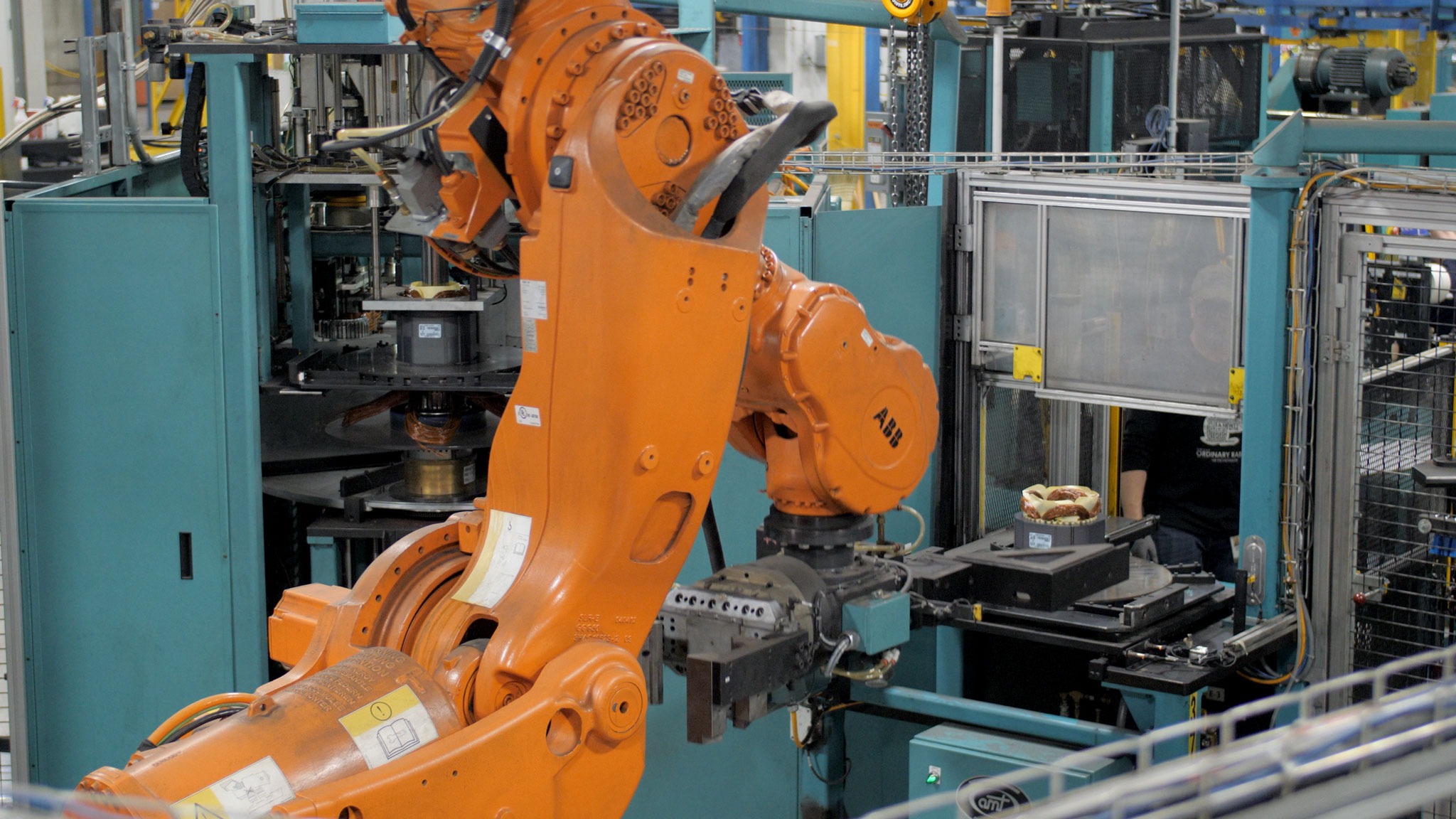

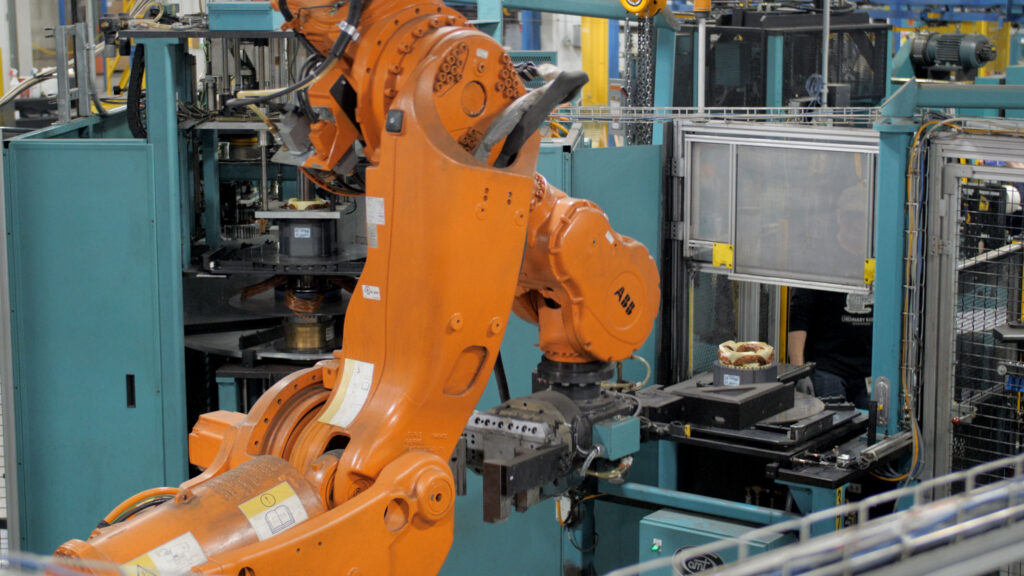

Electrification, automation and data-driven optimization are empowering industries to redesign their operations and enhance efficiency. From energy monitoring to predictive maintenance (PdM), these technologies are foundational for success in a low-carbon economy — enabling companies to improve performance while reducing emissions.

Sustainability isn’t just good optics; it delivers measurable returns. Energy-efficient equipment reduces operating costs, PdM cuts downtime and smart automation can extend asset life. Over time, these improvements contribute to lower total cost of ownership and increase throughput. As energy prices fluctuate and carbon regulations tighten, plants that proactively modernize their operations will maintain compliance and strengthen the bottom line.

Accelerating the energy transition and sustainability

Industrial transformation today is more than compliance — it’s about building smarter, more resilient systems that outperform in both sustainability and productivity. Electrification and automation are reshaping production environments, logistics networks and plant operations by cutting waste, reducing downtime and optimizing energy use.

At the core of this transition is a move away from fossil fuels. High-efficiency electric motors are engineered to reduce energy consumption across demanding applications. Smart automation platforms and industrial software enable real-time monitoring, control and PdM — improving uptime and optimizing plant operations.

Advancements in automation and electrification are central to a net-zero future vision, enabling smarter, more sustainable operations. But to fully realize these benefits, maintenance teams must adopt digital tools, monitor data from connected equipment and perform condition-based interventions. Upskilling in areas such as internet of things, energy management and sustainability best practices is therefore critical. Forward-thinking organizations are investing in training programs that empower technicians and engineers to actively contribute to the energy transition — turning sustainability goals into on-the-ground action.

Tackling emissions through innovation

For plant engineering teams, reducing emissions — whether direct, indirect or value chain-related — is a complex challenge that demands advanced integrated solutions. In practice, this means implementing technologies to minimize fossil fuel dependence, increase operational efficiency and support circular business models. To achieve substantial progress, businesses must transition from fossil-fuel-based processes to electrical and technological alternatives that detect and mitigate greenhouse gas leaks, such as methane.

To maximize impact, companies should focus on four key areas:

- Energy efficiency: Technologies such as high-efficiency motors, energy management systems and smart grids help industries reduce their energy consumption and carbon footprint. Electrification of industrial processes further supports the reduction of reliance on fossil fuels.

- Carbon intensity reduction: By shifting to electric alternatives, industries can reduce their carbon intensity, particularly in sectors like manufacturing, transport and building operations. Electrified solutions and high-efficiency drives enable industries to minimize emissions across their operations.

- Waste and environmental footprint reduction: Innovative practices like lean manufacturing and circular design reduce waste and increase resource efficiency. Additionally, reducing emissions associated with production processes helps mitigate environmental impact.

- Enhanced circularity and flexibility: Adopting a circular economy approach, industries can design products for durability, reuse and recyclability, reducing waste and minimizing the environmental impact of end-of-life disposal. This approach also reduces resource dependence, enhancing supply chain resilience.

Addressing scope 1, 2 and 3 emissions

Effective emissions reduction requires a focus on all three scopes defined by the Greenhouse Gas Protocol.

- Scope 1 — direct emissions: These emissions from owned or controlled sources by the company, such as fuel combustion in vehicles, boilers or other industrial processes. Companies can reduce Scope 1 emissions by adopting electric alternatives and optimizing operations.

- Scope 2 — indirect emissions from purchased energy: Scope 2 emissions come from the generation of purchased electricity. Reducing these emissions requires integrating renewable energy sources, improving energy efficiency and adopting energy management systems.

- Scope 3 — emissions from the entire value chain: Scope 3 emissions are often the most challenging, as they involve emissions across the entire supply chain. Reducing these emissions involves collaborating with suppliers to adopt sustainable practices, designing products for durability and recyclability and educating customers on the efficient use and maintenance of products.

Barriers to emission reductions, sustainability

While momentum toward emissions reductions continue to build, the path to achieving sustainability goals remains challenging. Some of the top obstacles include:

- Reliance on fossil fuels: Still accounting for over 80% of global emissions and transitioning away from them requires significant investments in renewable energy infrastructure.

- High upfront costs: Implementing energy-efficient solutions often involves high upfront capital costs, which can be a significant barrier for many small and medium-sized enterprises.

- Infrastructure limitations: Many existing systems are not designed to support modern technologies, creating a need for infrastructure upgrades.

- Budget constraints and data gaps: Access to accurate data is crucial for managing emissions. Many companies lack the necessary tools to track and optimize energy use, making it harder to make informed decisions.

- Policy and behavioral hurdles: While policy changes are critical, there is also a need for widespread behavioral change across industries to embrace sustainable practices and innovations.

Overcoming these barriers requires a concerted effort from all sectors of the economy. Collaboration with suppliers, policymakers and technology providers is critical to creating an ecosystem that supports emissions reductions. By working closely with suppliers, companies can influence the sustainability of the materials they source and improve the energy efficiency of their entire supply chain.

Similarly, policy changes that support clean energy infrastructure and provide financial incentives for green technologies will accelerate the transition. Companies that engage with both suppliers and policymakers to drive systemic change can create a more sustainable and cost-efficient future.

Building a circular, low-carbon world

A sustainable future depends largely on the transition to a circular economy — one that designs products and systems for durability, reuse and recyclability. By extending the lifespan of products and materials, industries can reduce waste, lower resource consumption and minimize emissions across the supply chain. This shift not only supports compliance with tightening environmental regulations but unlocks substantial cost-saving opportunities through improved resource efficiency and waste reduction.

Adopting circular practices strengthens supply chain resilience, reduces environmental impact and positions organizations for long-term competitiveness. Industry leaders are aligning with evolving regulatory and reporting standards — such as the EU Taxonomy Delegated Act, Global Reporting Initiative and SASB Standards — to set and exceed expectations.

Sustainability practices across all manufacturing fronts

The journey to net-zero is a shared responsibility that requires action across all sectors — governments, policymakers, industry leaders and communities must collaborate to create the necessary conditions for a low-carbon economy. This includes creating supportive policies, investing in clean technologies and sharing best practices.

The path to net-zero is clear: every step taken — whether by adopting energy-efficient technologies, shifting to electric systems or improving supply chain sustainability — moves industries closer to a more sustainable future. By embracing innovation and collaboration, industries can achieve sustainability goals and play a leading role in the global movement toward a low-carbon world.

Every efficient motor, every electrified process, every avoided emission moves us one step closer. Manufacturing leaders should continue pushing forward because when industries lead, the planet thrives.