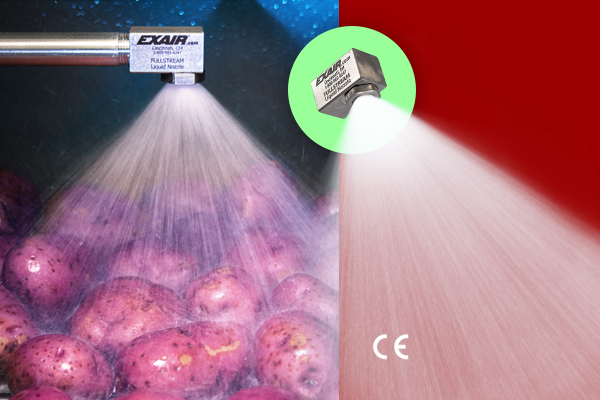

EXAIR’s Liquid Atomizing Spray Nozzles require no air to operate. They produce droplets by spinning the liquid and breaking its surface tension through a precision orifice or by impacting the liquid on to a surface of the nozzle. Compared to EXAIR’s Air Atomizing Spray Nozzles, liquid atomizing spray nozzles generate more liquid volume and produce a coarse spray pattern. The higher liquid flow rates benefit some common industrial applications like cleaning, cooling, rinsing, dust suppression and washing. Many liquid atomizing spray nozzles operate well when the liquid they are spraying contains particulate or is a slurry.

They are good general-purpose nozzles for industry and are commonly used with inexpensive liquids like water, rinse aids or detergents while also very effective with chemicals, pesticides and herbicides. Adjustment of the liquid flow rate can be done with varying liquid pressure but without the same adjustability or refinement of Air Atomizing Spray Nozzles. Their smaller footprint allows for mounting in smaller spaces and with less plumbing required, since no air line is needed. Liquid nozzles, made of Type 303 stainless steel, are durable and rugged, with no moving parts and have a maximum operating temperature of 800°F (427°C).

These spray nozzles are CE compliant and come in variety of sizes. They complement EXAIR’s large line of Air Atomizing and No Drip Air Atomizing Spray nozzles. https://exair.co/79-lndir