Measuring is critical to the reliability of rotating equipment.

Much has been said and done to produce the “perfect” fit for rolling element bearings in motors and other rotating equipment. Assembly of these machines requires that either the inner fit to the shaft (journal) or the outer fit to the housing (bore) is able to slide; so if one fit is tight, the other must be loose. While “tight” and “loose” are relative terms that must be defined in the quest for the perfect fit, any fit that’s too loose or too tight can lead to early bearing failure and costly downtime.

A tight (interference) fit is usually recommended for motor bearing journals. Standard fits for radial ball bearing journals range from j5 to m5; the standard housing fit is H6 (see Table 1). These are the “standard” fits and may be different depending on the machine designer’s understanding of the application.

Table 1 also shows that the tolerance band generally widens as bearings get larger, and that the journal fit is always interference (shaft journal is larger than bearing ID), while the bore fit is always line-to-line (housing bore is the same dimension as bearing OD) to loose (housing bore is larger than bearing OD).

Extreme care when measuring

Interference fits and loose fits are expressed in “tenths” (a unit equal to 0.0001 in. or 2.54 microns; μm), a level of precision that requires extreme care to measure accurately. A recent study involving 16 machinists in nine service centers found that experienced machinists with calibrated, well-maintained micrometers should have no problem measuring journals within ±2 or 3 tenths (±5.1 μm to 7.6 μm). The same study, however, found that 25% of the measurements of certified master rings of known dimensions were off by 10 tenths to 20 tenths [0.0010 in. to 0.0020 in. (25 μm to 51 μm)], in most cases due to lapsed calibration intervals and improper use of machinists’ standards.

A note: Typical calibration intervals are 1 year; determine what is appropriate for your facility or the service center you use. There should also be written calibration procedures to follow. The best machinists compare each tool to the standard gauge each time they use a different one. Good practice indicates checking each tool at least once each day it is used. Proper technique is the other part of the equation. This method verifies both the tool and the user.

Bearing journals

Figure 1 illustrates the importance of precise measurement for the journal fit of a 6210 bearing for which the acceptable limits are 1.9686 in. to 1.9690 in. (50.002 mm to 50.013 mm). For example, if a machinist measures 1.9687 in. (50.004 mm), the measurement appears to be acceptable. However, if the machinist is only able to measure to within ± 2 tenths (± 5.1 μm), the confidence factor that the measurement is in tolerance decreases to 75% of the capability, because only 3 of 4 tenths will fall within tolerance-i.e., everything from -1 tenths to +2 tenths will be in tolerance while -1 to – 2 will not. For example, 1.9687 in. to 0.0002 in. = 1.9685 in. and would be out of tolerance.

A journal fit that is too tight will preload the bearing (reduce its internal clearance), which will increase the friction and temperature and lead to premature bearing failure. It is also important not to exceed the tolerance in the other direction. If the fit is too loose, it will allow movement ranging from micromotion to the bearing spinning on the shaft. The latter usually results from the combination of a loose fit and an increase in the internal friction of the bearing.

Increased internal friction may have several causes including poor or degraded lubrication, bearing race damage, and excessive preload. If this type of damage occurs, the bearing eventually will spin even if the fit was originally in tolerance.

Bearing housing bores

The same principles apply to bearing housing bores. If the fit is too tight, the bearing can be damaged during an aggressive assembly attempt (i.e., a large mallet). If it is too loose, there may not be enough friction between the outer race and the bearing housing bore to prevent movement ranging from micromotion to the bearing spinning in the housing. It is also possible for the fit to be within tolerance at ambient temperature but expand at operating temperature, allowing the bearing outer race to move, especially with aluminum housings.

Effects of small motions

Micromotion occurs when a variable load is applied and there is room to move. Though limited to an extent by the fit tolerance band, it can still happen under the right conditions because the housing bore is loose by design.

Radial load tends to inhibit micromotion, and a strong, consistent radial force can “pin” the bearing race to the bore. But the weaker the force, the greater the likelihood that the micromotion will occur (e.g., a perfectly aligned, direct-coupled application theoretically would have no radial load).

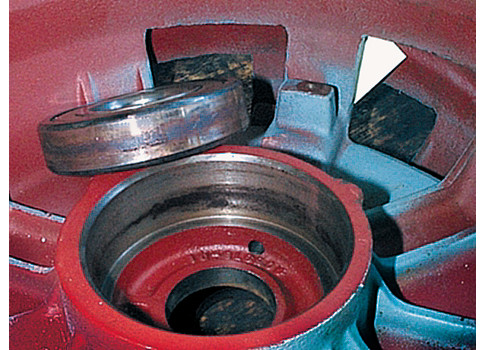

Micromotion causes fretting (mechanical wear at the surface), which will appear as small rusty patches on the bearing inner or outer race, or on the housing or shaft (see Figure 2). Because the oxidized areas are usually harder than the bearing surfaces, fretting can accelerate mechanical wear. Under the right circumstances, fretting can occur on either fit. Bearing fits are critical to the reliability of rotating equipment. Application conditions including the type of driven load, the connection to that load (direct coupled or belted), and the proper bearing for the application are all factors to be considered in achieving the correct fit.

It is of utmost importance, however, that machinists use properly calibrated measuring tools and the correct techniques to ensure accurate measurement of these precision tolerances. Not only must the gage be calibrated according to the appropriate schedule, but also it should be compared to the standard regularly—at least daily.

If these measures are taken and fretting still is a problem, several anti-fretting compounds are available on the market. Talk to your bearing vendor.

Jim Bryan is a technical support specialist at the Electrical Apparatus Service Association (EASA), St. Louis. A CFE Media content partner, EASA is an international trade association of more than 1,900 firms in 62 countries that sell and service electrical, electronic, and mechanical apparatus.

Table 1. Bearing fit tolerances (shaft fits are lowercase, housing uppercase).

The Bottom Line:

- While “tight” and “loose” are relative terms that must be defined in the quest for the perfect bearing fit, any fit that’s too loose or too tight can lead to early bearing failure and costly downtime.

- There should also be written calibration procedures to follow. The best machinists compare each tool to the standard gauge each time they use a different one. Good practice indicates checking each tool at least once each day it is used. Proper technique is the other part of the equation. This method verifies both the tool and the user.

- Bearing fits are critical to the reliability of rotating equipment. Application conditions including the type of driven load, the connection to that load (direct coupled or belted), and the proper bearing for the application are all factors to be considered in achieving the correct fit.

Key Words

Here are some of the articles at www.plantengineering.com, KEYWORD: BEARINGS that further discuss this topic:

Procedures For Protecting Electric Motor Bearings

Contamination can dramatically shorten bearing life and lead to costly downtime. Maintenance professionals should be knowledgeable about the effects of contamination and well-trained in the procedures to prevent it. There are five basic ways to maintain bearings and reduce the number of failures caused by contamination.

Debunking the myths around bearings

The wheels of industry turn on bearings, so why do the wheels often vibrate, clatter, squeak, drag, and overheat? Bearings can fail for lots of reasons. Most failures are related to lubrication and contamination, but myths and misconceptions handed from one generation of maintenance engineers to the next help perpetuate many easily avoidable problems. These myths fall into three general areas of bearing use: installation, misapplication, and lubrication.

Solutions to fan and blower bearing problems

Fans and blowers are simple pieces of equipment, yet require a lot of maintenance, particularly for bearings. The higher the speed, the more problematic they become. This article details how to avoid common problems caused by the improper selection of pillow block housings, seals, bearings, lubricant and lubrication systems.