Is there a major difference in the risk assessments done in North America and Europe?

Safety is a double-edged tool in that it not only protects plant personnel but it also increases productivity and provides cost savings. On top of that, companies who implement safety functions perform functional safety evaluations, and implement safety in manufacturing processes by following the guidelines stated in the machine safety standards and complying with their requirements find benefits that go straight to the bottom line.

There are other financial benefits to implementing safety standards. For example, meeting safety specifications is globally understood and respected, which can in turn open up more global opportunities. Another factor is insurance companies have started to recognize machine safety compliance and its benefits, which can have a positive influence on insurance premiums.

When it comes right down to it, safety provides a safer and a more efficient work environment. Let’s face it, every year there are just over 4,600 employee deaths in industry, with another 50,000 that die from illnesses caused by exposure to workplace hazards, according to OSHA. On top of that, six million workers suffer nonfatal workplace injuries. The annual cost to U.S. businesses ends up being more than $125 billion, according to OSHA. Safety can truly be the source of a competitive advantage because it can reduce the total cost of goods and the total cost of risk. It can impact productivity along with image and reputation.

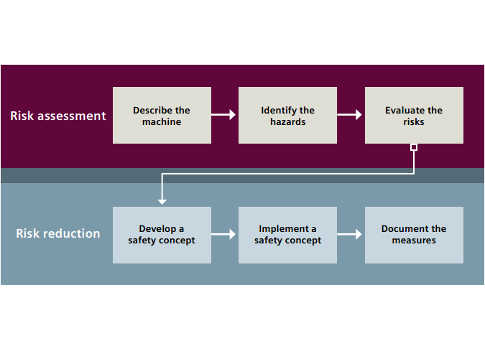

But before a manufacturer can reap any benefits, they should understand just which machine standard or standards to follow. That is why when making a risk assessment you should be able to analyze and understand the differences between ISO 12100 and ANSI B11.0.

Read the full white paper here.