Whenever we initially meet with a new client, the first (and ultimately most important) point that we introduce at the meeting is the fact that there is only one reason for our discussion — money. When your initial focus is on money, your perception of O&M improvement changes from reduced PM cost to an increased ROI from your maintenance expenditures.

Whenever we initially meet with a new client, the first (and ultimately most important) point that we introduce at the meeting is the fact that there is only one reason for our discussion — money.

When your initial focus is on money, your perception of O&M improvement changes from reduced PM cost to an increased ROI from your maintenance expenditures. This is a significant, if not dominant, factor in the development of maintenance optimization strategy. The basic reason behind this is the realization that PM costs are quite small in comparison to the price that can ultimately be paid if the resulting CM (reactive maintenance) and loss of output (unavailability) are not properly addressed. Figure 1 provides a simple but very realistic picture that depicts the model that should drive maintenance optimization strategy.

Notice that two of the money factors in Figure 1 are cost items. Most organizations look only at these two elements of this picture — and thus treat maintenance as a cost burden in their company that must be tolerated, but minimized in any way possible. But look what happens if you are smart enough to consider the entire picture, and include the third element of plant output. The financial loss from reduced plant output might likely overshadow any money that might be spent on PM or CM if your output is less than its rated capacity. In other words, maintenance has been and continues to be a major factor in the company’s ability to achieve profit! We believe that this suggests a very strong argument for our belief that maintenance is actually a profit center for your company, not just a cost factor to be tolerated as a part of the company’s cost of doing business. This may be a very new notion to some of you, but the acceptance of maintenance as a profit center (not cost center) is a real element in producing dramatic bottom-line impact, and the first step in moving your organization toward what constitutes World Class Maintenance.

The traditional maintenance mindset

Engineers and technicians are always “optimizing” something. Terms such as design optimization are commonly employed in the technical world. In recent years, we have added Maintenance Optimization to our lexicon, and, as management focus has more frequently turned to various O&M issues, we hear more and more about Maintenance Optimization.

Webster defines optimization as “to make as effective, perfect or useful as possible.” Thus, we could reasonably define Maintenance Optimization as “making our inspection, servicing and repair/replace actions as effective and useful as possible.”

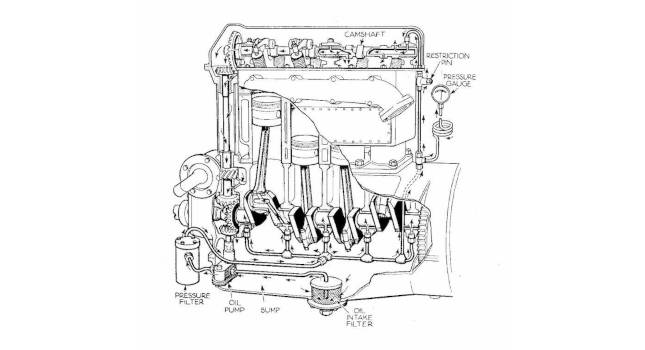

When we look back over the 1950s, 1960s and 1970s, maintenance engineers and technicians attempted to follow this definition by keeping all equipment within their purview in a serviceable state. And, more often than not, this involved intrusive actions that were both time consuming and susceptible to human error. The result was an increase in return visits or service calls, hardly surprising when there is much evidence that such human error occurs about 50% of the time. As equipment complexity, consumer demand for high levels of quality and availability and worldwide competition steadily increased, so also did the need develop for more maintenance and maintenance resources (people, tools, software) in order to meet our objective to keep everything in a serviceable state.

Simply put, what had developed as a mindset in the maintenance world was a practice that was based on the notion to preserve equipment. That is, keep everything up and running—or at least, available to run and in a perpetual serviceable state.

Rethinking maintenance strategy

The 1980s produced a rude awakening across the U.S. industrial complex. What had been essentially a U.S. monopoly in the world marketplace {1/2} for three decades suddenly became a global arena of fierce competition for virtually every product line that was “made in the USA.” Not only did the price of goods to the ultimate consumer become the dominant force, but the bar was continually being raised on consumer demand for quality and service.

In all of this, two things happened in the maintenance world that changed its very soul forever. First, management found that capital investment for new plants and equipment was frequently not a viable option if the bottom line was to remain favorable. What this meant to the maintenance world was that the reliability and availability of existing plants and equipment had to increase. Second, like everyone else, maintenance was also called upon to “Do More With Less.” In other words, the resource-intensive philosophy of Preserve Equipment had to change.

As we began to rethink our maintenance strategy, we also began to realize that the Preserve Equipment mindset was seriously flawed. For example, four of the most serious problems that went unnoticed for decades were:

1. We had inadvertently promoted an environment where everything was equally important and was maintained to keep it in a serviceable state irrespective of its level of importance to production, safety or quality.

2. We had also created an environment where decisions were made to perform maintenance simply because there was an opportunity to do so. In a typical scenario, a plant would schedule an outage to specifically service, say, a boiler. But we would then additionally schedule all sorts of maintenance on other equipment just because it was possible to do so.

3. As a result of the above, we were overly conservative on our maintenance actions, actually doing more than was necessary in some instances. This often resulted, not only in wasted resources, but also in damage to the equipment from our intrusive actions.

4. Then, as the downsizing syndrome set in, the Preserve Equipment modus operandi really overwhelmed us because we couldn’t keep up with everything. Our planned maintenance actions fell further and further behind, backlog mounted and, worst of all, we found our operation becoming almost totally reactive.

A new paradigm was needed to address all of these issues. We had to sharpen our decisions on how to effectively use resources that were shrinking, and we had to introduce new technologies that would refine our brute force approach to maintenance. Most importantly, we had to change back from a reactive to a proactive mindset. This new paradigm is embodied in the RCM process.

Printed with permission from Butterworth-Heinemann, a division of Elsevier, from RCM—Gateway to World Class Maintenance, by Anthony M. Smith, AMS Associates Inc. in California, and Glenn R. Hinchcliffe, Consulting Professional Engineer, G&S Associates Inc. in North Carolina. Copyright 2004. For more information about this title and similar titles, please visit www.books.elsevier.com .