As the Internet of Things (IoT) infiltrates the industrial sector, forward-thinking organizations will find ways to leverage the Industrial IoT for more efficient, productive and intelligent operations. Here's a closer look.

The Internet of Things (IoT) will significantly alter manufacturing, transportation, distribution and other industrial sectors over the next decade, according to the World Economic Forum. We’ve only hit the tip of the iceberg in terms of the ways Internet-connected devices will transform these industrial sectors. To put a number on the anticipated growth of Industrial Internet of Things (IIoT) over the next few years, Accenture places conservative spending estimates at $500 billion worldwide by 2020.

Forward-thinking businesses are already leveraging the power of the IIoT and reaping the benefits. When used effectively, it allows companies to better manage their operation, increase production and transform business for the better.

Let’s take a look at how industrial organizations should be harnessing IIoT to set their businesses up for future growth.

Create efficiency through a better understanding of operations

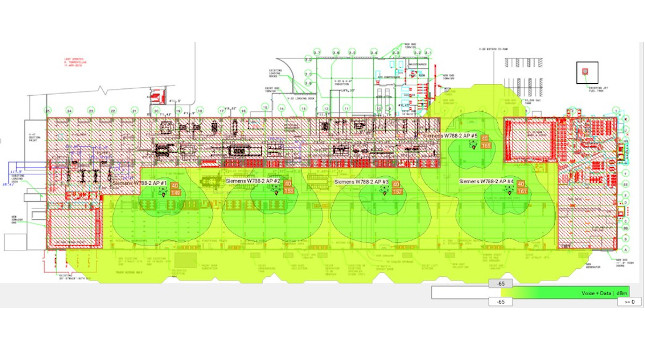

One of the key opportunities with the Internet of Things is the ability to gain insight, refine processes and create efficiencies. Internet-connected devices dispersed throughout a warehouse offer visibility into every area of complex systems.

"Operational efficiency is one of the key attractions of the IIoT, and early adopters are focused on these benefits. By introducing automation and more flexible production techniques, for instance, manufacturers could boost their productivity by as much as 30 percent," wrote the authors of Accenture’s "Driving Unconventional Growth Through IIoT."

Increased visibility through smarter technology allows manufacturers to gain insight into complex processes and respond more quickly. Embedded sensors and other advanced instrumentation paired with software, applications and vision systems yield valuable data that can be used to make better operational decisions. Many companies are also leveraging intelligent technologies to conduct predictive maintenance of assets, which cuts down on unplanned downtime, avoids costly breakdowns and reduces overall maintenance costs. It also creates the potential for increased throughput.

Increase production, explore new business models

Optimizing operations has another benefit—it frees up manpower and machines to take on other work, whether that’s increased production or exploring new lines of business.

Highly repetitive tasks, such as palletizing or sorting, can be completed faster and more efficiently by an intelligent machine. The availability (and affordability) of smarter technologies means machines can take the place of humans in these highly repetitive tasks, thereby increasing safety and improving ergonomics in the workplace. Leveraging automation also gives production lines predictability.

Consider these impressive statistics from the American Society for Quality: More than half of manufacturers are currently in the cloud and, of this percentage, 82 percent have increased warehouse efficiency, 49 percent have noted fewer product defects and 45 percent have experienced higher customer satisfaction.

With the integration of smart technology, there will be shifts in the workforce and the opportunity to offer new services, improve products and explore new markets.

Leverage smart technologies to drive innovation

One of the game-changing aspects of the IIoT is the opportunity to bring together what has traditionally been two distinct categories of data: information technology and operational technology.

Accenture predicts that vendor-specific and proprietary infrastructure will be replaced over time with interoperable platforms. Harnessing the data through sensor-driven computing, industrial analytics and intelligent machine applications opens the door for innovation.

"By deploying these capabilities, companies can weave together previously unavailable, or inaccessible, enterprise- and machine-generated data to create new monetization opportunities," the Accenture report states.

Armed with insightful data, forward-looking companies should think about how they can commoditize on that technology by either expanding products or offering new services.

Final thoughts

Manufacturers who want to thrive and compete need to take advantage of what the IIoT has to offer-and the sooner, the better. The opportunity, according to General Electric, could be as high as $32 million worldwide. Making the investment in smarter technology, whether it’s machine technology, intelligent sensors, advanced analytics or, ideally, a combination of all three, sets the stage for future growth and development.

Scott Stone is the director of marketing for Cisco-Eagle, a provider of integrated material-handling and storage systems for industrial operations. Scott has 25 years of experience in industrial operations and marketing. Edited by Joy Chang, digital project manager, CFE Media, [email protected]