The first step in this "make it yours" approach was to make the company's problems visible.

When speaking proudly of using Lean to achieve excellence, AJ Oster has a single, overarching message. The company is committed to being "one in the horizontal connection of purpose, process and people."

Headquartered in Warwick, R.I., being "one" is quite a feat for North America’s largest processing distributor of copper, brass sheet, strip and foil, and its six service centers spread across two countries and Puerto Rico. Equally impressive is its ability to nurture a Lean culture within a business that began 94 years ago, when manufacturing had a significantly different look and feel.

"When done properly, Lean can engage even your most veteran employees," said Joe Headdy, the company’s director of OpX (operational excellence). "People who were never or rarely formally involved in solving problems are now involved. They used to just come in and do what they had to do. Now, we are fully engaging more employees in the process."

In addition to its Warwick headquarters, the manufacturer employs 300 people across its remaining service centers in Alliance, Ohio; Carol Stream, Ill.; Yorba Linda, Calif.; Caguas, Puerto Rico; and Queretaro, Mexico. AJ Oster’s products serve a range of industries, including ammunition; antimicrobial; art and jewelry; automotive; building and construction; coinage; consumer; electronics and electrical; energy; and industrial.

When Headdy initiated managing for daily improvement (MDI) after stepping into the newly created OpX role three years ago, he said the company was "familiar" with Lean and was having sporadic success across the divisions with a "disconnected" approach to the practice. "They had some success with kaizen events, but we wanted to take a more holistic approach and involve more employees," said Headdy, who previously worked for Ford Motor Company and witnessed Lean in the auto manufacturer’s assembly plants.

Beginning as a pilot Lean initiative at the Alliance facility two years ago, its primary strategic objectives have remained the same, which include having a world-class safety performance and culture, being an industry leader in customer service, leveraging volume growth with its current resource base (equipment and people) and sustaining its business well into the future.

AJ Oster’s vision statement states: "Our company vision is that AJ Oster will become the premier value-added service center in each of our target markets by delivering dynamic, innovative solutions to our customers and leveraging the full potential of our employees. We will achieve earnings growth by marketing new metal products and entering new markets."

A "make it yours" approach

Often referring to the way in which it tailors Lean to its needs by saying the company "Oster-sized it," the first step in this "make it yours" approach, Headdy said, was to make the company’s problems visible. So members of management placed whiteboards around the plants to facilitate transparency and engagement at all levels.

Each board contained a space for a metric, a countermeasure to the problem and a planning section. "Make things visible, work on it and keep it fixed—or sustained," Headdy said.

"With the use of whiteboards, it doesn’t get buried in a laptop. Even our annual business plan uses a whiteboard to map out the entire year." According to Headdy, the "motherboards," as he lightheartedly refers to the whiteboards, were so effective inside the plants that it wasn’t long before the Lean team implemented them in other areas of the company, including sales and purchasing.

The use of the whiteboards in that area, as in production, allow employees a voice and a visual path toward realizing departmental goals, Headdy said. The boards also serve as a backdrop to daily management process meetings. A time clock keeps teams on track to not exceed 15 minutes on any one issue.

One of the most important elements of the daily meeting, Headdy said, is to keep it from becoming a punitive environment. "You cannot use the meeting as a whipping stick, because then people won’t surface the problems, and they’ll go underground," he said. "We coach people how to address problems in daily improvement meetings so it doesn’t look like finger-pointing. We focus on solving a problem, assigning a solution, staying accountable and establishing a metric. It takes the focus away from the punitive approach. And the whiteboard makes it visual without being personal."

As a result of its Lean initiative, AJ Oster routinely leverages kaizen events to involve all employees, from hourly to general managers, Headdy said. It hosts a monthly OpX call between all six of its facilities to share updates.

"The six sites are primarily independent, but we’re working toward being ‘one Oster,’" Headdy said. "I guarantee that the other sites have been there, done that with similar problems-or they will."

Champions for Lean

Headdy firmly believes in having someone at each facility to "champion" Lean, someone who lives it each day, particularly since he can’t be at every plant every day. The manufacturer’s Puerto Rico plant was the last of its six facilities to begin the Lean journey and has been involved for less than a year.

"We have different levels of maturity between the plants," Headdy said. "But even with language barriers at our Mexico and Puerto Rico sites, people can understand and comprehend the visual colors, like our red and green metric charts indicating how we are performing at any given moment."

While Headdy says that company leadership supported Lean from the start, some employees were skeptical. Still, he believes the best part of the company’s Lean transformation has been the engagement of the people. "In the beginning, most people don’t like it. It takes patience and coaching. But once you get a leader, everyone figures out that they can really use this," he said. "We want the people who are doing the work to come up with the ideas. This is about engaging employees. It may take a little longer at the operator level to understand and accept the changes. But now they feel like they have a voice."

Headdy says employees understood that accepting Lean was expected. Company leaders cultivated a sense of trust with employees by explaining the "whys" of Lean, sharing financial information, quote times and metrics. AJ Oster made it clear that the Lean journey was never about a particular person’s performance but rather the bigger picture of the company and all who contributed to its daily success. "We’re all here to make a living for our families, and what’s good for the company is good for us," Headdy said.

Lessons learned

Bob James, the Carol Stream facility vice president and general manager, said each of the company’s six facilities was focused on continuous improvement, but that its OpX efforts had improved daily focus, aligned all employees, improved communication and cost savings.

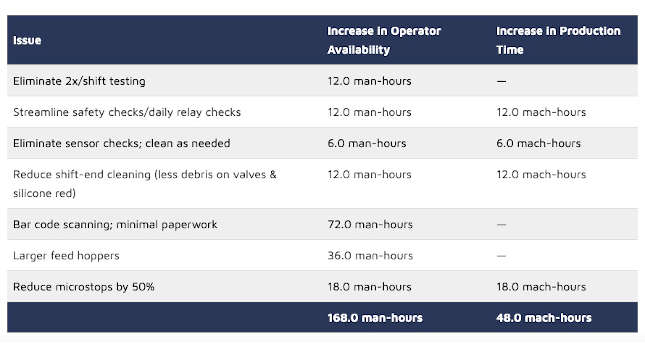

"It’s offered continuous education for employees on areas they weren’t involved in previously and empowered everyone to make decisions with that additional education," James said. AJ Oster’s Lean success has produced some impressive company metrics, as well. Results from projects across the six divisions include: Order entry errors have improved by 30%; overtime reduction has improved by 35%; quotation time has improved by 30%; aged inventory has experienced a 26% improvement; inventory turns have improved 8%; and the company’s on-time performance has improved by 7%.

Eager to share important lessons from its Lean journey, Headdy said the most important takeaways are to get a Lean coach; communicate; train and change management; establish benchmarking; start with a pilot site or area; make it yours; have patience; stay the course; and involve employees at all levels. "It’s not a magic bullet. Visibility, patience and persistence are key.

You start slowly," Headdy said. "Once it gains some steam at the pilot site, you purposely invite additional employees to the meetings. Eventually, they figure out that Lean is not a foreign language."

Susan Fotovich Mccabe is writer at Association for Manufacturing Excellence "Target Magazine." This article originally appeared on the "Target Magazine Summer 2016" issue. Edited by Joy Chang, digital project manager, Plant Engineering, [email protected].