IIoT offers both new challenges and opportunities for manufacturers willing to push the boundaries of machine and plant design. Included in these new opportunities are benefits such as connectivity, efficiency, and reliability, but many features of IIoT technology may bring great financial benefits to manufacturers as well.

The benefits of the Industrial Internet of Things (IIoT) are becoming more apparent as industry experts debate the opportunities at hand. Ushering a new era of connectivity, where plants and machines work together in a secure and collaborative way to enable technology at the service of people, IIoT is providing greater empowerment and efficiency. While the potential for data and efficiency gets most of the attention, the smartest manufacturers today are leveraging IIoT technologies to uncover inefficiencies in processes and turn them into working capital. Therein lies the power and economic benefits of the IIoT.

IIoT offers both new challenges and opportunities for manufacturers willing to push the boundaries of machine and plant design. Included in these new opportunities are benefits such as connectivity, efficiency, and reliability, but many features of IIoT technology may bring great financial benefits to manufacturers as well.

Increasing profitability with IIoT

In manufacturing, IIoT can deliver improved traceability for better supply chain efficiency, which brings about faster production and lower costs. Additionally, when today’s existing Big Data technologies for storage and analytics are combined with machine-to-machine communication, smart machines are able to consistently capture and communicate data better and more efficiently.

Analyzing historical data allows manufacturers to identify inefficiencies in production and other areas of improvement for reducing time to market. It also allows them to better manage operating expenditure (OPEX) and business intelligence efforts for customers, as well as create new business opportunities for asset management, such as predictive maintenance, that enable vast cost savings.

For example, the use of connected devices and dynamic QR codes provide fast and efficient customer service. Information can be distributed more quickly, and, in turn, operators are able to solve production problems in a more efficient manner, driving greater customer satisfaction and continued loyalty. In addition, operators can use radio-frequency identification to track and monitor production, inventory, and logistics moving forward. With IIoT, manufacturers are enabled with a more consistent and continuous lifecycle management process than ever before. These are just a few examples of the plethora of opportunities with smart, connected devices at hand.

But when it comes to IIoT, the economic benefits can differ greatly between OEMs and end users. OEMs need to focus on providing new or enhanced services to their customers while end users need to put a greater focus on managing OPEX. In general, the variances can be broken up into two areas:

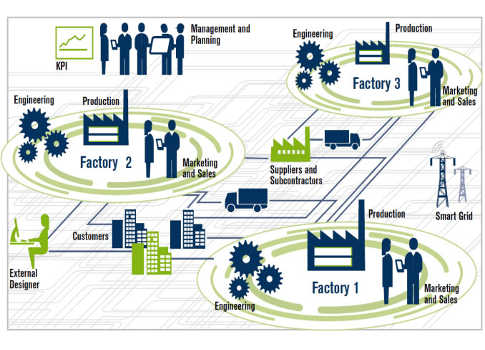

- End users: With the increased need for interoperability between information technology and operations technology, transparent data, and machine access, end users will be able to update brownfields and integrate smarter machines, leading to smarter factories. With these changes, there is an opportunity to provide a connection point that delivers a holistic view of operations from the shop floor to the top floor.

- OEMs: On the other hand, OEMs need to provide enhanced interfaces and features to reduce downtimes, improve machine performance (depending on the production status and demand), and provide remote monitoring, predictive maintenance, and safety. The behavior and data of machines and components have changed, so manufacturers need to take advantage of the different opportunities for growth as well.

It is also important to remember that IIoT influences the manufacturing enterprise from an engineering, supply chain, and customer-relations management perspective in regards to profitability. With IIoT, manufacturers can become a more customer-service-centric provider rather than just a component supplier. The data enabled by IIoT gives manufacturers more flexibility to meet customer needs. With this new ability, manufacturers are able to generate fresh business opportunities as customers are brought to the forefront of attention in the manufacturing operations landscape.

IIoT beyond automation

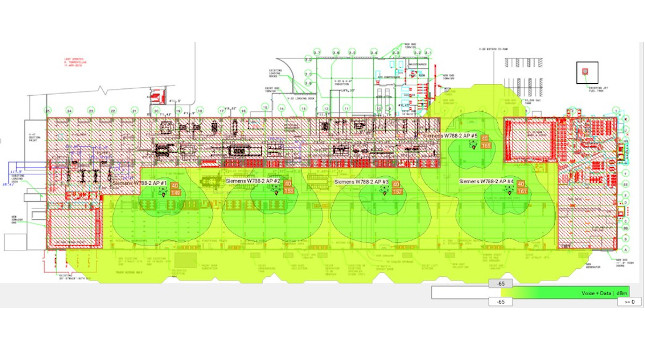

When it comes to identifying cost savings, many see the benefits of IIoT as connected solely to industrial automation. Though industrial automation is an important aspect of the IIoT, there are major cost-effective benefits through energy efficiency in smart machines and factories, too. Every machine or plant has an energy profile that should also be a part of the description of an IIoT architecture. Energy consumption—and managing it efficiently—implies that manufacturers know what is happening on the shop floor. The IIoT now gives us the ability to link and analyze information from different sources that impact the plant-even information from outside of the plant such as weather.

We’ve connected smart factories to a smart grid and vice versa, which leads to smart, connected, comprehensive ecosystems with IIoT at the center, providing the interface that gives a holistic view and brings about additional benefits of energy efficiency and sustainability. IIoT is transforming the industry, and manufacturers aiming to stay ahead of the trend are working to address the changes while profiting from the benefits. When implementing IIoT technologies, manufacturers can maximize profitability by improving time to market and enhancing services.

Another important consideration is to start IIoT implementations selectively and incrementally adding or modernizing existing equipment and infrastructures. This will allow IIoT platforms to go toward research and development spending rather than investing in component development. Additionally, manufacturers should look at applications like operational efficiency, asset utilization, data monetization, and software-driven services in order to drive economic benefits and increase return on investment. As manufacturers become more comfortable with IIoT’s capabilities, long-term applications can be achieved, including structural changes, pay-per-outcome models, connected ecosystems, and a human-machine workforce.

With these future applications, the economic benefits of IIoT will far outweigh the challenges it requires to get there. The IIoT is here to stay; and to the winner goes increased efficiency, lower costs, and an improved competitive position, ultimately providing better chances to survive and prosper in this new world.

Ralf Neubert is senior director of innovation and technology in the industry business sector of Schneider Electric.