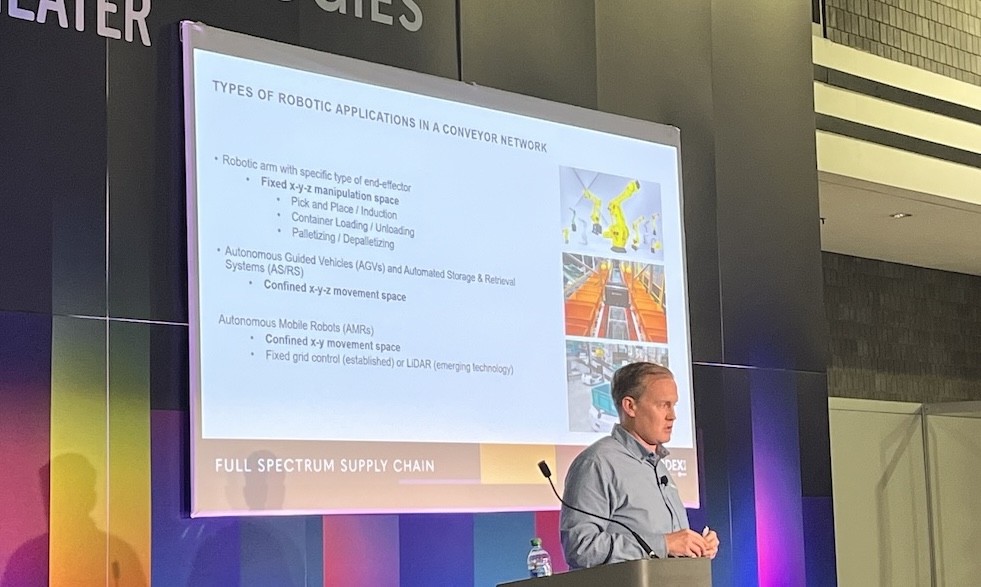

Material Handling

Material handling is the movement, protection, storage and control of materials and products throughout the manufacturing, distribution, consumption and disposal process. It involves the coordination and movement of raw materials, in-process inventory and finished goods, as well as the associated information, documentation and equipment necessary to perform these tasks.