Tangible benefits of using wireless technology include cost reduction, more reliable control/processing systems and improved worker productivity. Wireless technologies may be used to build a plant-wide wireless network connecting mobile workers to the production and/or business network. Maintenance workers can now access important data (such as a PLC program or recipe) while observing a malfunc...

Tangible benefits of using wireless technology include cost reduction, more reliable control/processing systems and improved worker productivity. Wireless technologies may be used to build a plant-wide wireless network connecting mobile workers to the production and/or business network. Maintenance workers can now access important data (such as a PLC program or recipe) while observing a malfunctioning device or inefficient process.

So, the simple answer is: Every industry now benefits from wireless technologies as part of their automation systems.

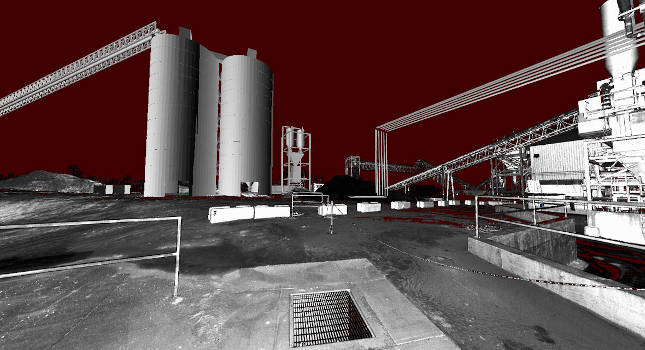

Oil and gas

As the demand and cost of energy rises, energy companies are investing billions in exploration and production to meet the world’s energy needs. Automation technologies play a key role in making oil and gas extraction economical. Wireless also plays a key role as more remote locations are explored.

Oil and gas production, refinery and distribution systems benefit greatly from spread spectrum technologies as part of PLC, DCS and SCADA communication systems. Wireless applications include communications to very remote sites devoid of phone/cellular service, cost-effective reliable alternative to leasing phone lines, significant cable installation cost savings at tank farms and refineries, faster installation and dismantling of drilling rigs and quicker data collection and monitoring tools for mobile workers. In addition to solutions for SCADA and PLC/DCS automation, wireless may also be used for remote video surveillance for security and process control monitoring as well as voice-over IP (VOIP).

Water and wastewater

Automation strategies for this industry have dramatically lead to reduced manpower costs, better drinking water quality and adherence to environmental regulations. Wireless is an integral strategy for this industry.

Similar to the oil and gas industry, water and wastewater systems often require long range communication to remote pump stations, lift stations, flow meters, reservoirs and storage tanks. This is an excellent fit for wireless technologies as it further reduces the water authority’s monthly operating costs by eliminating phone line charges. Initial investment into wireless communications will return considerable costs savings over the years just in phone line cost savings.

Remote pump stations lift stations and tanks may all be linked back to the treatment plants PLC network. Because water tanks are usually located at the highest peaks, they make excellent repeater locations for achieving unobstructed line-of-sight to the remote pumps.

Wireless remote SCADA systems that are Ethernet based can also easily support operator interfaces (HMIs) at remote locations. Remote video for security is also supported with high speed wireless Ethernet systems.

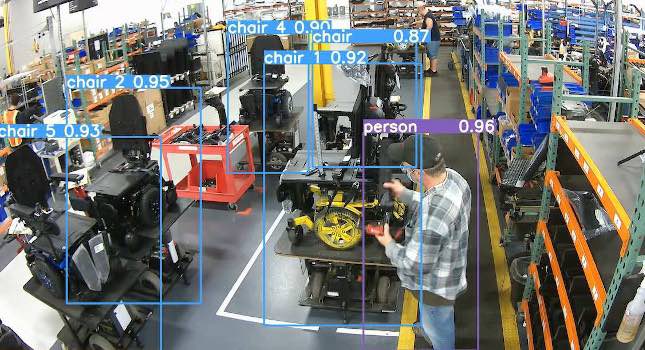

Factory automation

Wireless plays an important role in factories and processing plants. Industries such as consumer goods manufacturing, metals, automotive, pharmaceutical, food processing, packaging and material handling can benefit greatly from wireless technologies.

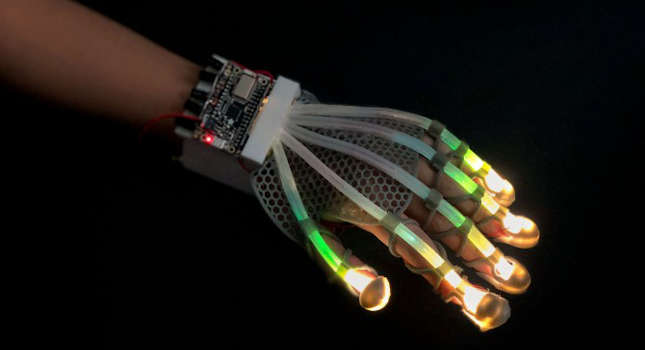

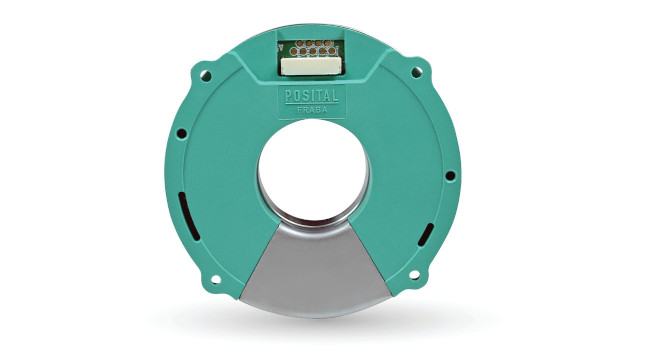

Wireless is also an excellent solution for communication to controllers on moving platforms for material handling systems such as overhead cranes, automatic guided vehicles (AGVs), transfer cars, turntables and conveyor systems. Wireless provides high speed communications (such as for Ethernet) while not suffering from mechanical wear and tear as wiring harnesses, festooning, inductive rails and slip rings commonly do. Wireless is a great strategy to improve production by eliminating downtime.

Video is becoming an important part of industrial systems both for remote surveillance (security) and remote process monitoring. High speed wireless technologies offer a way to cost-effectively add video information to the control and monitoring system.

Finally, wireless technologies have expanded beyond traditional serial and Ethernet networks, and to other industrial networks and protocols. Wireless solutions are now available for PROFIBUS and HART permitting remote sensors and actuators to be connected to the main control system (PLC or DCS) without the need for hardwiring.