What does a company do when it can't afford a power outage? For instance, Harbec Plastics of Rochester, New York, produces highly engineered plastic parts with short lead times, using a computer numerical controlled (CNC) production process. A momentary power failure burdens Harbec with hours of reprogramming and production set up.

What does a company do when it can’t afford a power outage? For instance, Harbec Plastics of Rochester, New York, produces highly engineered plastic parts with short lead times, using a computer numerical controlled (CNC) production process. A momentary power failure burdens Harbec with hours of reprogramming and production set up. Cutters might damage a part being made, losing days of work in process. After experiencing several outages, Harbec’s founder, Bob Bechtold, decided something had to be done.

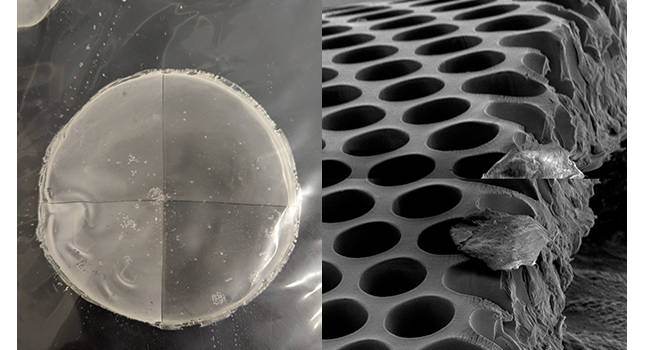

Bechtold looked at a wide variety of systems, and concluded that Capstone MicroTurbines would provide the best value for ultra-low-emission, continuous power. They also fit with Bechtold’s commitment to the environment. Every aspect of his operation is designed to minimize waste. Even the scraps swept off the floor become raw material used to create new products.

Bechtold’s state-of-the art array of two dozen Capstone MicroTurbines provides both high-quality prime power and dry exhaust heat to warm the 40,000-sq ft site. In summer, the exhaust heat fires an absorption chiller/desiccant, providing air conditioning with virtually no electrical load. Total system efficiency exceeds 70%.

For businesses with lengthy production processes or sensitive time delivery issues, power fluctuations can be especially costly. Onsite power systems provide an economically attractive alternative. Microturbines are among very few proven technologies capable of providing a continuous source of high-quality power with near-zero emissions and extremely low maintenance. Coupling them with heat recovery maximizes efficiency and reduces energy costs, creating a system that can pay for itself.

Capstone Turbine Corporation can be reached at 818-734-5300 or www.capstoneturbine.com . Contact Steve Chippas of MWH Energy Solutions for engineering and installation services at 630-836-8900.