In the 1970s electronics manufacturers began placing their underground and aboveground hazardous chemical piping systems within an outer jacket for the sole purpose of preventing leaks from getting into ground water supply. Part of the reason was inadequate performance of single-walled piping components.

Key Concepts

Double containment piping must withstand the corrosive effects of the fluid being conveyed.

Lack of leak detection compromises the secondary containment pipe.

Cathodic protection for metal pipe overcomes the effect of breaks in the outer coating.

Sections: Leak detection Detection systems Components Expansion Condensation Cathodic protection More Info:

In the 1970s electronics manufacturers began placing their underground and aboveground hazardous chemical piping systems within an outer jacket for the sole purpose of preventing leaks from getting into ground water supply. Part of the reason was inadequate performance of single-walled piping components.

Today, to meet EPA Standard 40 CFR, Part 280 for underground transport of hazardous chemicals a system must:

Be double contained

Have automated leak detection for pressurized systems

Have an outer containment able to withstand transported media for a minimum of 30 days

To provide secondary containment there are design parameters to be considered. Whether the system is a pressure pipe, drain, or waste system has a significant impact on the design, layout, material selection, wall thickness, and leak detection method selected. Whether a system is to be buried or above ground also has a impact on its design.

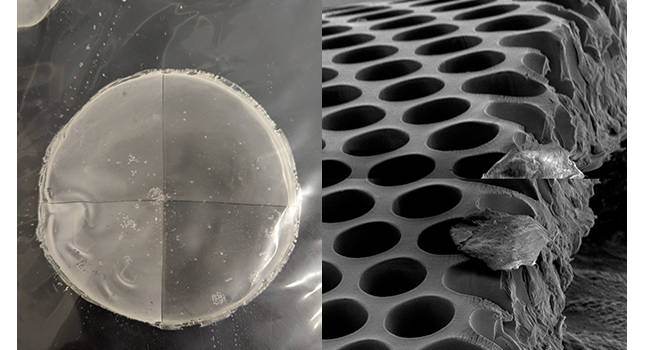

Space limitations are an important consideration. A piping system intended for tight pipe-rack installation or located near buried structures will have different installation requirements as well as material selection, wall thicknesses, pressure ratings compared to a system that has no space constraints (Fig. 1).

Pipe material selection depends on a number of factors. For primary piping, the chief consideration is the ability of the material to withstand the corrosive effects of the fluid being conveyed.

Similar criteria must be used for the outer piping. The interaction of the inner and outer systems, how they are tied together, the joining method, how joining affects system installation, compatibility of the secondary system, and joining methods for both are all factors in selecting the combination of materials used.

The choice of materials to be used must include risk analysis. The time and duration that the contained fluid will be in contact with the outer piping must be anticipated. The outer pipe must meet EPA mandated retention guidelines of 30 days when exposed to the transported media, so the possibility of failure from the environment or other damage must also be considered.

Since there may be only infrequent contact with the corrosive fluid in a properly designed system and the time of contact may be short, a less expensive outer pipe may be appropriate in some applications.

A complete double containment piping system is one that is engineered, designed, installed, started up, and operated successfully. To engineer a system involves more than procuring components. Double containment piping systems, by their nature, usually have unique requirements and need custom design (Fig. 2).

Leak detection

Leak detection is one of the most important aspects of double containment piping systems. Without an effective and reliable means to sense that a leak has occurred, the additional protection provided by secondary containment is compromised.

Once a fluid leaks into an annulus of a pipe, only a primary means of containment exists unless tertiary containment is in the system design such as placing the double-walled pipe into a tertiary concrete structure.

Left undetected, a fluid may corrode through the secondary containment or find its way through defects in the containment to the surrounding environment. It is important that a leak be detected as early as possible so any chance of fluid escaping is minimized.

The successful implementation of any leak detection system is related to many aspects of the design and installation of a piping system. It is essential that leak detection be considered from the conceptual phase of the project. By doing so, any needed design details or installation procedures may be taken into account and carefully coordinated.

Detection systems

Continuous line leak sensing and locating systems are referred to as leak detection cable. The cable is able to determine the approximate location of the leak soon after it occurs. Several types exist, each based on the continuous measurement of an energy source monitoring for changes (Fig. 3).

Two most common methods are conductive or resistance based cable systems where the resistance of an electrical signal is continuously measured and an impedance based system.

Time-domain-reflectometry continuously monitors the impedence of an energy pulse wavelength and measures it against a set pattern to detect changes. Both are capable of determining the approximate location of a leak.

Both sensing systems claim an accuracy in detecting leak location to within

Dividing the double containment piping systems annulus into isolated compartments can also provide leak detection. Each compartment can be monitored with a probe.

Typical probes include liquid level sensing, moisture detection, vapor detection, conductivity and resistivity, pH measurement, pressure sensing, flow measurement, density measurement, wavelengths of light, radar or sonar, and motion detection. These sensors can be combined for added effectiveness.

An advantage of point probe systems is the ability to customize the system, but an inherent disadvantage is the lack of ability to locate a leak with precision.

Noncontinuous sensing of double containment piping systems includes those methods that do not involve any type of continuous measuring device. The three main noncontinuous sensing methods are manual detection, visual detection, and periodic annular pressure monitoring.

Manual detection is done by installing drip legs with valves in above-ground systems and low point sumps with risers to the ground surface in underground systems, or by positioning drip legs with valves in manholes.

Visual detection requires a transparent material on the outer piping. Again, it is most effective when used in a regular inspection program.

The pressure of an annulus can be occasionally monitored to detect if a leak has occurred. A pressure gauge must be placed in the outer pipe and monitored periodically.

While a double containment system can be designed without leak detection, the effectiveness of the system is lessened without it.

Manual systems can be a cost effective and efficient method of leak detection and usually are useful as a backup. Noncontinuous systems are nonspecific in locating leaks unless there are very frequent locations for visual or manual monitoring.

Components

Dimensional information is needed for straight piping sections for both metallic and nonmetallic piping. Each unique section of straight piping should have all details clearly indicated, except for tightly fitting, intensive projects where only short lengths of straight pipe exist.

Details that must be shown for a typical straight pipe section, or specified clearly include: material of construction, with reference to the appropriate ASTM or AISI specifications, all inside and outside diameter sizes, annular space size, wall thicknesses, tolerances, location and type of internal and external supports, leak detection cable, and references to detail drawings.

There are two layout issues to which the customer of a double containment piping system must pay special attention to at the start of a project. First, will the overall size of the double containment piping and its components fit in the space available.

While this aspect of double containment piping sounds obvious, it often is a source of surprise and frustration for a plant engineer. This side of double containment piping is a limiting factor, particularly when a system is being installed as a retrofit into an existing facility.

A second major item has to do with allowing sufficient clearance for primary fittings to be installed or fabricated within secondary containment fittings. Adequate clearance must be provided between components. This is important for all systems, especially those requiring an internally flexible design.

Expansion

When adequate room to prevent piping contact due to differential expansion and contraction between primary and secondary containment elbows does not exist, the diameter of the secondary containment elbow may be increased. In systems that have a significant amount of thermal expansion, expansion loops, offsets, or changes in direction might be required to achieve the desired level of flexibility.

Expansion joints may be added to inner or outer pipe sections. Most nonmetallic materials have a linear coefficient of expansion that is far greater than metals and they are subject to early failure when restrained.

Where other methods are not suitable, expansion loops offer an alternative method to compensate for thermal expansion and contraction. Loops may be positioned vertically or horizontally and may vary in configuration.

An expansion offset assembly is very similar to an expansion loop. The design requires the same general rules that are applied to expansion loops. Expansion offsets can also be positioned in either a horizontal or vertical configuration.

Condensation

If air that is warm and humid is in the annulus of a double containment piping system, it will condense when the system is subjected to a colder temperature. This occurs when a system is constructed during the summer and later subjected to winter temperatures.

Condensation may cause the leak detection system to give a false alarm. Frequent false alarms may cause operators to ignore them — a dangerous practice and self-defeating practice, as metal materials are subjected to corrosion from the water.

The solutions are simple and inexpensive. You can replace the air with a dry or inert gas, or a vacuum can be pulled into the annular space if inner and outer pipe components are mechanically strong enough. It is erroneously assumed this is an involved and expensive procedure. If an annulus is designed to be leak-tight and provided with adequate vents and drains, this task will be one of the least expensive aspects of the project.

Cathodic protection

Cathodic protection is a method of inhibiting corrosion. It is applicable to all types of pipe metals. The pipeline is connected to an anode bed to make the pipe behave as a cathode so the anode bed corrodes and not the pipe (Fig. 4). Where this is not practical, passive protection may be attained by attaching sacrificial anodes directly to the pipe.

Cathodic protection is particularly important for coated pipe to overcome the effect of pinholes or breaks in the coating. These permit local corrosion cells to form. Being localized, these cells are highly active and can rapidly penetrate the pipe wall.

More Info:

The material contained in this article was obtained from companies that build double containment piping systems and various piping handbooks. Article edited by Joseph L. Foszcz, Senior Editor, 630-288-8776, [email protected] .

Plant Engineering magazine extends its appreciation to Asahi/America for help in preparing this article.