Modernizing equipment can lead to a safer facility.

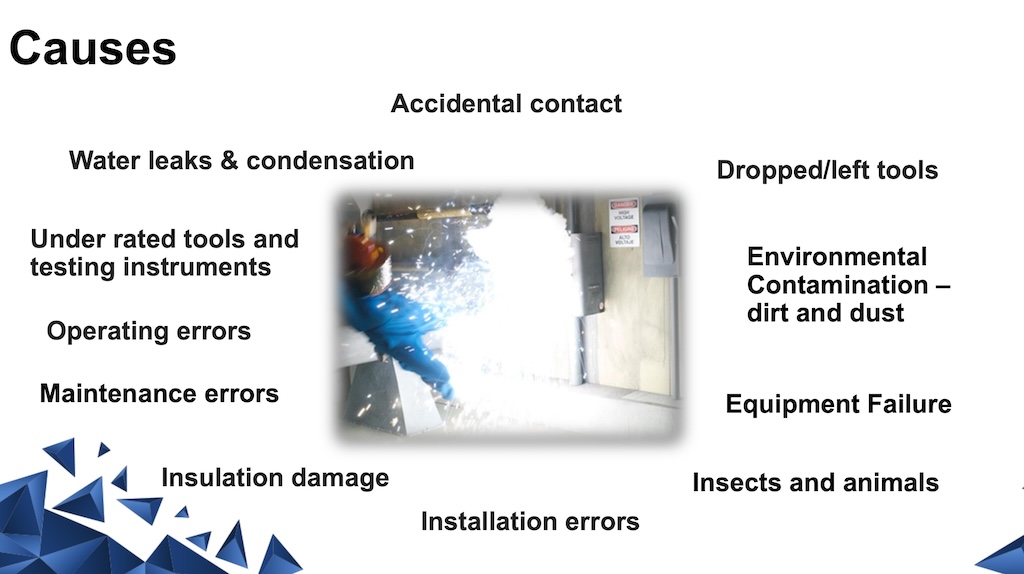

For electrical engineers and electrical workers, the risk of arc flash hazards is a primary safety concern. Arc flash events produce high-energy outputs of heat and pressure, reaching temperatures as high as 35,000 degrees F, and cause electrical explosions that put workers at severe risk for burn injuries and, in some cases, fatality.

Knowing and understanding the dangers of arc flash is key to preventing them, and regulatory agencies have worked diligently to put specific requirements and guidelines into place to combat these hazardous incidents. But adhering to these rules is really only the first step on the path toward electrical workplace safety.

Facility owners can go further to help ensure worker safety in electrical environments by implementing sound strategies that include modernizing existing electrical equipment and incorporating safety by design, in which safety is inherently enabled in all electrical situations.

Modernizing for increased safety

NFPA 70E: Standard for Electrical Safety in the Workplace is the primary industry standard for compliance for U.S. organizations to promote safe electrical workplace practices. Under this standard, organizations must adhere to a number of steps to achieve compliance including auditing current workplace environments, developing safe practices, conducting an arc flash risk assessment, conducting regular training and audits for electrical workers, maintaining electrical equipment and providing employees with proper personal protective equipment.

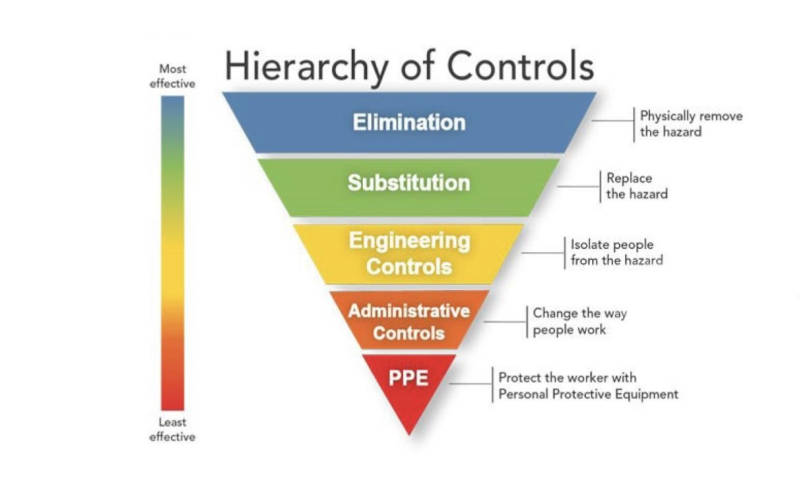

It is worth noting that many of the steps and procedures outlined by NFPA 70E, while effective, are required after equipment has already been installed. The often-overlooked and informative Annex P, however, provides further guidance for implementing protective strategies that aim to eliminate risk altogether, rather than simply respond to it. These guidelines include incorporating a cycle of continuous improvement: plan, check, do and act (PCDA). In implementing these four steps, organizations can reduce the risk of electrical arc flash for their workers.

One main way to plan for safety and reduce electrical-hazard risk is to implement engineering controls, which can be enhanced by proper device selection and the modernizing of existing electrical equipment. It is no secret that many of today’s facilities are aging. Technology that is 15 to 20 years old does not include modern safety features, and some even older equipment may not even meet the standards for electrical safety required by modern regulation.

Equipment maintenance, while important to maintaining safe environments with older technology, often does not go far enough to ensure worker safety in an electrical environment. Properly maintained equipment is still subject to two key phenomena:

1. It may no longer be sustainable due to technological advances.

2. It ultimately degrades and reaches the end of its useful lifecycle.

As facilities upgrade and electrical loads change, existing equipment often is not equipped to support evolving electrical requirements. Aging equipment is also at a higher risk for arc flash incidents due to failing materials, corrosion, dust and debris buildup and other factors.

It often makes sense for facility owners to upgrade to modern equipment to address these issues. Upgrading to new equipment can have significant financial and safety benefits for a facility:

- Reduced maintenance costs. Existing circuit breakers require periodic maintenance, especially as they age. In some cases, components for existing circuit breakers may not be supported. Replacing circuit breaker equipment to the latest technology can help to reduce a facility’s current maintenance costs.

- Increased reliability. Maintaining consistent power is one of the key ways to reduce the risk of arc flash. Older circuitry may have dash-pot-style trip devices that can have a higher failure rate and be more susceptible to foreign material contamination. Upgrading circuitry can increase the power reliability in an electrical environment, leading to a safer work environment.

- Enhanced safety capabilities. Modern equipment has inherent safety capabilities and technological advancements that cannot exist in older equipment. Modern technology has arc-flash-resistant features, like arc-fault-current interruption and arc-extinguishing technology.

When considering upgrading equipment in existing structures, worker safety is paramount. Many organizations are consulting outside sources to help them identify where to implement modernization tactics to reduce the risk of arc flash. These benefits factor into the consideration for equipment modernization in existing structures. Incorporating modernization into facility planning in existing facilities is a good tactic for ensuring safe electrical environments.

Safety by design

In new structures, facilities owners should be taking safety even further. Along with designing structures for energy efficiency and optimal space use, organizations should consider safety as a key factor in design plans for structures where electrical loads are present.

The concept of "safety by design" incorporates engineering controls, modern technology and design features to help ensure a safe environment at the outset. Making fundamental design choices to promote electrical safety can reduce the risk of arc flash and even prepare facilities for any adjustments in electrical loads that may occur in the future.

Two design strategies that mitigate the risk of an arc flash event include specialized relaying, such as light-sensing technology, or incorporating virtual main-relay systems. Both of these examples lower arc flash energy by reducing the arcing time. Remote racking and digital controls can also be incorporated in design and reduce workers’ exposure to arc flash.

Facility owners that select the correct and proper equipment in the initial design phases are at an advantage, ensuring the safest possible environment for their workers right from the start of installation. Oftentimes, enlisting third-party engineers to assist in the design phase can help to identify areas where electrical safety measures can be incorporated. Those who wait and perform arc flash analyses after installation may face costly adjustments and find solutions difficult to implement. The alternative, to incorporate modern equipment right from the planning and design phase, can be a less costly and ultimately safer decision.

Maintaining a safe environment

Meeting regulatory standards for electrical safety is not only essential to worker safety, it is an OSHA requirement. In some cases, implementing the regulatory steps after equipment is installed may not be enough to mitigate and prevent the risk of arc flash incidents. Organizations that want to create the safest possible work environments are thinking ahead of incidents by modernizing equipment and designing spaces for safety.

Whether planning for modernization of equipment in existing facilities or implementing design features to create safe electrical work zones in new structures, facility owners need to be aware of the risk of arc flash incidents and consider the best possible ways to ensure worker safety.

John Blaylock is senior director of operations for U.S. services and Doug Beck is in power system engineering, U.S. services for Schneider Electric.