Rockwell Automation Fair highlights process-sector push

A steady stream of acquisitions by Rockwell Automation is enhancing its appeal in process industry verticals. The automation giant—historically strong in discrete and hybrid sectors—also owes part of that momentum to software activities. A key part of this activity is enabling new application offerings to plug into the service-oriented architecture (SOA) developed by the company's R...

A steady stream of acquisitions by Rockwell Automation is enhancing its appeal in process industry verticals. The automation giant—historically strong in discrete and hybrid sectors—also owes part of that momentum to software activities.

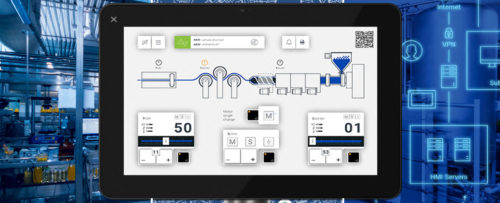

A key part of this activity is enabling new application offerings to plug into the service-oriented architecture (SOA) developed by the company’s Rockwell Software unit. Fundamental to this SOA is the FactoryTalk Services Platform, a set of core services such as security, directory, and data access for Rockwell’s FactoryTalk suite.

Kevin Roach, VP, Rockwell Software, says the SOA services are being extended into new and acquired offerings that bolster Rockwell’s process-sector appeal. For example, not only did Rockwell partner with OSIsoft a year ago to market historian technology under the Rockwell name, it has worked closely with OSIsoft so that the resulting product launched at the show—FactoryTalk Historian Site Edition (SE)—makes use of FactoryTalk Services.

“This new version is integrated with the FactoryTalk suite through FactoryTalk Services—the SOA that we’ve built,” says Roach. “This offers some excellent connectivity.”

For example, the next step in Rockwell’s “tiered” and “distributed” historian strategy is to introduce a historian embedded within Rockwell’s ControlLogix rack. This solution will be called FactoryTalk Historian Machine Edition (ME), and because it too will tap into the services, it can plug into site historians.

Rockwell’s most recent acquisition is the October purchase of Pavilion Technologies, a vendor of advanced process control software for process and hybrid industries. Pavilion’s software taps into historians for past data on process variability, which it then crunches with algorithms to fine-tune plant processes. Rockwell will add FactoryTalk SOA support to Pavilion’s software so that it can easily plug into historians and other applications, says Roach.

Rockwell’s other acquisitions add appeal in the process industries:

-

ICX Triplex (2007) . ICX has critical control and safety solutions for process industries.

-

GEPA (2006) . The German vendor offers change-management software for industrial automation products from multiple vendors.

-

Datasweep (2005) . Under Rockwell, Datasweep’s manufacturing execution system (MES) has evolved into FactoryTalk ProductionCentre, with process capabilities such as a weighing & dispensing component.

-

ProPack Data (2002) . Today the vendor’s MES is called RS PMX. Its deep industry functionality will be redeveloped as common components with ProductionCentre.

-

Attendees of the annual Rockwell Automation Fair can take the opportunity to view automation and information management technologies from Rockwell, and dozens of its partners. In pharmaceuticals, a focus on creating common MES components will allow PMX users to migrate to the ProductionCentre architecture over time, says Roach. The first step was outfitting PMX to communicate with other systems via FactoryTalk Integrator middleware. The next component was weighing & dispensing, followed by electronic batch records (EBR).

James LaBonty, associate director of automation engineering for Wilmington, Mass.-based Wyeth Pharmaceuticals , says EBR allows managers to electronically review exceptions. Wyeth is interested in FactoryTalk Integrator as an updated means of integration to an SAP ERP system.

One of Rockwell’s MES goals is an SOA-enabled “horizontal” functionality that can be combined as components for industry solutions.

“We’re building industry applications on top of that horizontal platform,” says Roach. “The idea is to take the service dollars down, which takes the overall deployment cost and time down, takes risk down—making the solutions more broadly available.”

Do you have experience and expertise with the topics mentioned in this content? You should consider contributing to our CFE Media editorial team and getting the recognition you and your company deserve. Click here to start this process.