Optimize automation design for serviceability

Machine builders specializing in factory automation and assembly systems are challenged at every turn. Capital equipment investment is high, material and labor costs are increasing, competition is growing fiercer and customers are demanding faster delivery. It’s not surprising that machine manufacturers are constantly seeking ways to contain costs and increase efficiency, while maintainin...

Machine builders specializing in factory automation and assembly systems are challenged at every turn. Capital equipment investment is high, material and labor costs are increasing, competition is growing fiercer and customers are demanding faster delivery.

It’s not surprising that machine manufacturers are constantly seeking ways to contain costs and increase efficiency, while maintaining strict quality and performance standards. One approach that has worked for many automation industry leaders is adoption of a design engineering strategy that standardizes on configurable machine parts, wherever possible, in order to replace unique custom-designed components with more modular and readily accessible ones.

For machine builders, this strategy has proven effective in helping reduce engineering and production time and costs — often as much as 50%. However, what many have also learned is that specifying modular, configured parts rather than custom parts has also helped their customers by making it easier to maintain and repair equipment.

Faster access to configured parts allows end users to eliminate the time, expense and hassles associated with ordering custom-designed parts. They can also reduce the need for substantial replacement parts inventory.

The importance of serviceability

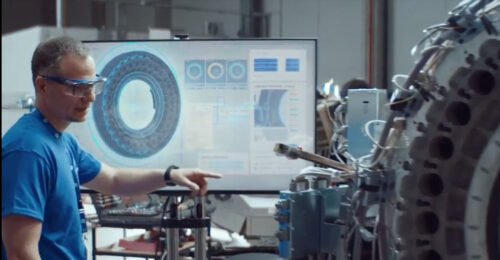

Like automation system producers, plant operations and control engineers also face challenges. Their role is to keep mission-critical operations up and running smoothly, safeguard worker safety and see that quality standards are met. To do this, they need to ensure that machines are monitored and equipment is maintained and serviced properly. They need to ensure that replacement parts are readily accessible when required. In their world, unscheduled downtime caused by equipment failure is simply not an option.

In any machine, many mechanical parts are subject to wear and tear and must be maintained, and repaired or replaced. High stress parts need to be replaced more frequently so they don’t malfunction and cause production problems. In fast-moving plant automation lines, machine wear is caused by physical forces such as load, torque, friction, impact shock, heat, vibration, length and frequency of motion as well as humidity and any other atmospheric factors — all of which can have a negative impact on the performance and reliability of the machinery over time.

Modular, configurable parts can help

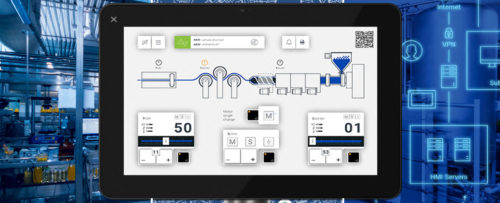

The concept of standardization is simple, yet effective. Some commonly used configurable parts include linear shafts, actuators, linear guides, ball screws, bushings, locating pins, metal plates, extrusions and conveyor rollers.

Machine builders can specify the parts in various sizes, material hardness and coatings and sometimes can order specific tooling modifications. Once a part has been configured and the model downloaded, it can be added to that machine’s bill of materials. Some part suppliers will even standardize the part within its product database, assigning it a unique part number for fast and easy replacement ordering.

Adding value

The benefits that automation system end users can derive when their equipment manufacturers specify configurable parts include:

-

Fast, easy ordering of replacement parts with short lead times mitigates the need to maintain safety inventories of replacement parts; an order is quoted and placed with a part number — not a drawing

-

MRO time and cost savings, because configured parts are less costly and can be ordered and delivered faster than custom replacement parts

-

Product life cycle information can often times be obtained for each discrete configured component from the machine builder and/or part supplier detailing the average life expectancy of each part (or mean time between failure), based on formulas that measure the effects of physical forces to which the part is subjected

-

Higher return on assets for capital equipment is also achievable as a result of keeping automation machinery and systems in optimum condition to deliver peak performance

-

Machine builders focused on optimizing machine designs for serviceability not only derive benefits for their own companies, but also provide significant and measurable value to their customers.

Do you have experience and expertise with the topics mentioned in this content? You should consider contributing to our CFE Media editorial team and getting the recognition you and your company deserve. Click here to start this process.