Cooper Bussmann “invisions” a solution to pinpoint open circuits, minimize downtime

One minute of downtime in the automotive industry can cost nearly $350,000. Even though unscheduled downtime is a common and costly problem for many manufacturers, actual numbers like these can be startling. Many plants are shocked to discover just how much short-circuits and overloads actually cost.

One minute of downtime in the automotive industry can cost nearly $350,000. Even though unscheduled downtime is a common and costly problem for many manufacturers, actual numbers like these can be startling. Many plants are shocked to discover just how much short-circuits and overloads actually cost.

A new wireless system comprised of intelligent fuse monitors and mesh routers uses diagnostics and alert messaging to not only minimize downtime, but also track and record open circuit incidents. The Cooper Invision downtime-reduction system developed by Cooper Bussmann identifies open circuit events, and pinpoints their location.

The St. Louis-based division of Cooper Industries makes electrical & electronics circuit protection products. Its downtime-reduction system suggests replacement fuses and the appropriate level of protective equipment.

Questra Corp ., developer of the back end of the Invision downtime-reduction system, used Questra intelligent device-management technology on the Invision Gateway computer to oversee not only fuse and circuit monitors, but the gateway itself.

The system’s battery-powered intelligent fuse and circuit monitors transmit any changes in status to system routers, says Walt Rossi, a Questra company VP. Wireless mesh routers connect monitors to the system Gateway, which then encrypts data received from the routers and sends it to the command center servers via the Internet.

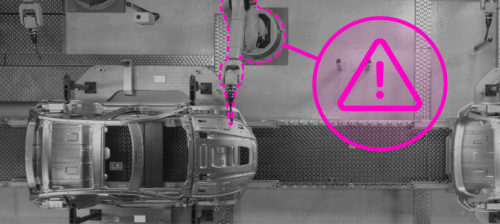

“Under normal operations, it takes 41 minutes to reestablish processes after a fuse opens,” says Joe Fox, director of systems services for Cooper Bussmann. “Now we can shorten that to about 16 minutes. Workers know where to go and how to make repairs.”

The command center displays the status of monitored circuits and allows easy configuration of alert escalation and trending reports. The command center initiates phone, email, or fax alerts.

Typically, workers discover an open fuse when a problem occurs during manufacturing. In industries that use hot and cold processes—such as metals—finding open fuses quickly is important, says Fox.

“In a refrigeration environment, for example, workers may not be aware that a chiller isn’t working,” says Fox. “In many cases, blown fuses are discovered too late.”

With the system’s command center, users can track open circuit events and run reports.

“At some of our beta sites, companies were replacing fuses, but not reporting them,” adds Fox. The system automatically tracks and records open circuit events when alerts are acknowledged.

The system also identifies recurring problems that operators might not know exist. Summary reports and trend analyses can be made to identify problem circuits that require remedial action.

“Applications for the Invision system are wide-ranging as a diagnostics tool, and for systems support,” says Deane Dray, a research analyst for Goldman Sachs . “Downtime is a very costly and painful problem, particularly with mission-critical equipment and processes. Any system that minimizes downtime adds value to a company.”

Adding wireless capability to a fuse is unique in the industry, adds Dray, as well as economical.

“Smaller, faster, and cheaper is the mantra,” he says. “The maturation of wireless fuse technology is similar to that of RFID, where chips have been miniturized enough to be economical.”

And what about ROI? Fox says users begin to reap the benefits of Invision within a year. “Many companies deploy the system in their most critical circuits, or areas of the plant that are most expensive.”

| Average number of blown fuses per year (by industry) |

| Automotive: 456 |

| Steel & aluminum: 534 |

| Petroleum/chemical: 156 |

| Average length of downtime |

| Automotive: 15.8 minutes |

| Steel & aluminum: 36.9 minutes |

| Petroleum/chemical industry: 63.2 minutes |

| Average cost of downtime per hour |

| Automotive: $1,320,000 |

| Steel & aluminum: $308,657 |

| Petroleum/chemical industry: $2,050,189 |

Do you have experience and expertise with the topics mentioned in this content? You should consider contributing to our CFE Media editorial team and getting the recognition you and your company deserve. Click here to start this process.