Top 5 Plant Engineering articles April 11-17, 2022

Articles about AI-based predictive maintenance, supply chain improvements, remote condition monitoring, industrial automation and future-proof manufacturing were Plant Engineering’s five most clicked articles from April 11-17, 2022. Miss something? You can catch up here.

The top 5 most read articles online, from April 11-17, 2022, for Plant Engineering covered AI-based predictive maintenance, supply chain improvements, remote condition monitoring, industrial automation and future-proof manufacturing. Links to each article below.

1. Getting started with AI-based predictive maintenance

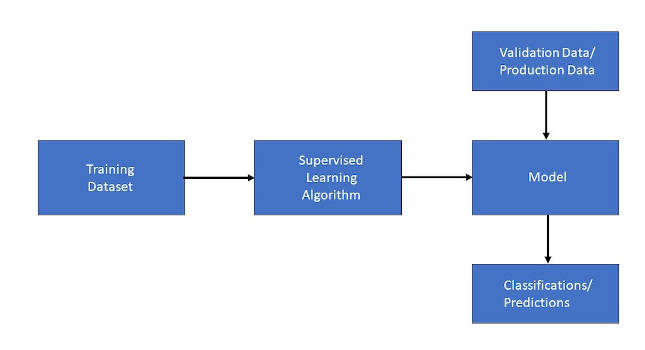

Artificial intelligence (AI), and particularly machine learning (ML), provide effective tools for implementing predictive maintenance.

2. Four ways to unshackle the supply chain

COVID-19 has caused many supply chain challenges, but being proactive and aggressive can help manufacturers reduce potential headaches. Four tips are highlighted.

3. Remote condition monitoring can alleviate worker shortages

Core maintenance KPIs are tied to increased work completion, reduced backlogs and improved mean-time-to-repair.

4. Industrial automation components with large axial forces require long linear movement

Applications include automation and robotics, machine tools, material handling and printing presses.

5. How IIoT, AI can help make future-proof manufacturing a reality

The Industrial Internet of Things (IIoT) offers manufacturers greater productivity and better information insights through artificial intelligence (AI) as companies look toward the factory of the future.

The list was developed using CFE Media’s web analytics for stories viewed on plantengineering.com, Apr. 11-17, 2022, for articles published within the last two months.

Chris Vavra, web content manager, CFE Media, cvavra@cfemedia.com.

Do you have experience and expertise with the topics mentioned in this content? You should consider contributing to our CFE Media editorial team and getting the recognition you and your company deserve. Click here to start this process.