Manufacturing digital transformation may start with consulting

Help needed for digital transformation? Most Chinese manufacturing enterprises have a strategic plan for digitalization; for those slow to start, consulting services may help digital transformation.

Learning Objectives

- Digital transformation includes a large array of technologies and integration.

- Consulting firms and automation providers offer digital transformation consulting.

- Creating a roadmap for digital transformation can increase probability of success.

Everything will be digital in the future. IDC predicts more than 60% of global GDP will be digital by the end of 2022. In June 2020, a media survey of chief information officers of nearly 600 Chinese manufacturing enterprises showed more than 99% of the enterprise leaders supported the digital transformation, and more than 70% of enterprises had a strategic plan for digital transformation.

However, digital transformation is full of difficulties and challenges. Some international research institutions believe less than 30% of the global digital transformation programs have been successful. In China, some experts even said that only 9% of the 40% of the enterprises in digital transformation in China are successful, and the real data may be lower.

Help wanted for digital transformation

For digital transformation of enterprises, “Do not know how to do” is the most common problem. Some enterprises regard digitalization as simple technical engineering of data flow for process control production. Some enterprises equate digitalization with the establishment of online channels and e-malls. Confusing beginnings often result in poor returns on investments (ROI), which discourages other companies from investing in the digital space.

Digital transformation technologies

Many concepts, theories and technologies relate to digital transformation, such as Industry 4.0, intelligent manufacturing, interconnected enterprises, industrial internet, edge computing, artificial intelligence, industrial cloud platform, digital twins, artificial intelligence of things (AIoT), industrial data centers and others. New concepts are always emerging, which creates confusion and makes the digital transformation path hazy.

How should manufacturers begin on the road of digital transformation? If the transformation success rate is 30%, how should manufacturers choose the right digital transformation solutions for industrial enterprises?

Digital transformation consulting

Digital transformation for manufacturing enterprises may begin with consulting.

Digital consulting can help companies find success using rich practical experience and methods appropriate for a manufacturing enterprise, carrying out suitable scientific planning, and gradually promoting it according to a roadmap, adjusting and communicating as needed to ensure a successful digital transformation implementation.

Digital transformation consulting companies

In the field of enterprise-oriented consulting, there are many well-known international companies. In the face of the current trend of digital and intelligent manufacturing, these consulting companies also have launched digital transformation consulting, and claimed many successful cases.

For example, Accenture put forward the digital transformation service system of “Industry X.0” in 2017, which helps the transformation of enterprise business model from the aspects of digital R&D, digital production, digital supply chain and digital service. According to Accenture, it has developed a detailed digital roadmap for a large oil and gas company based on the “Industry X.0” approach to change the way the business operates, achieving billions of dollars in revenue and reducing millions of tons of emissions.

Another consulting firm, McKinsey, in partnership with the World Economic Forum (WEF), publishes “Lighthouse Factory” every year, forming a global “best practice” learning platform. In China, it cooperated with Tsinghua University and other units to establish a digital capability development center in 2017, aiming to help Chinese enterprises successfully upgrade the manufacturing industry through digital transformation.

Automation vendor digital transformation

Beyond consulting firms, giants in the manufacturing industry and the digital field have launched consulting services. Well-known companies, practitioners and preachers, have boosted confidence for successful digital transformation for the manufacturing industry.

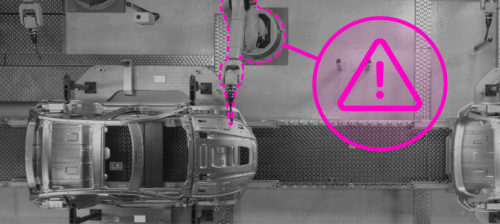

In 2016, Schneider Electric put forward the intelligent manufacturing concept of “diagnosis first, prescription after,” from consultation to implementation, emphasizing the diagnosis and evaluation of enterprises first. This let them promote the planning and deployment of each subsystem through the top-level design so they could realize the effective implementation of software and hardware digital solutions.

In January 2019, Lenovo, one of the world’s largest information technology (IT) product manufacturers, released a digital transformation consulting service, benchmarking against the world’s top consulting agencies and exporting its own digital capabilities. Starting from the three aspects of digital strategy, digital business and digital technology, with its own best practice set as a reference, Lenovo provides a full chain of consulting services such as planning, design and expertise for business empowerment in response to individual customer needs.

Siemens, a global provider in electrification, automation and digitalization, has been delivering digital technologies and products and practicing digital manufacturing for many years. These include the Siemens Amberg factory, the benchmark of the German automation industry, and the Siemens Chengdu factory, the closest to Industry 4.0. Siemens offers digital consulting services to external parties including Huaxing Glass. Services include formulation of digitalization strategic goals and blueprint, application architecture planning, technical architecture planning, thematic design, production management system design and digital factory implementation roadmap.

Clarify digital transformation

The complexity of industrial sites and the uncertainty of technological developments adds complexity to each enterprise’s digital transformation; it cannot be achieved overnight. Manufacturing digital transformation is a long-term project that requires a high degree of integration with what already exists in the enterprise. Before starting digital transformation, it may be wise to seek digital consultation first. Gaining digital transformation knowledge will undoubtedly increase probability of success for the digital transformation of enterprises.

Stone Shi is executive editor-in-chief, Control Engineering China; edited by Mark T. Hoske, content manager, Control Engineering, CFE Media, mhoske@cfemedia.com.

KEYWORDS: Digital transformation for manufacturing

CONSIDER THIS

Seeking help for digital transformation make accelerate opportunities over competitors.

Original content can be found at Control Engineering.

Do you have experience and expertise with the topics mentioned in this content? You should consider contributing to our CFE Media editorial team and getting the recognition you and your company deserve. Click here to start this process.