Software adds value to HMI, MES, ERP

GE Fanuc Intelligent Platforms launched Proficy Workflow, powered by the new Proficy SOA (Service Oriented Architecture). The industrial Business Process Management (BPM) software helps make human-machine interface, manufacturing execution systems, and enterprise resource planning systems more efficient.

Charlottesville, VA – GE Fanuc Intelligent Platforms , a unit of GE Enterprise Solutions, has launched Proficy Workflow, powered by the new Proficy SOA (Service Oriented Architecture). The product provides an industrial Business Process Management (BPM) solution to digitize and streamline production processes.

“Proficy Workflow brings the power and results of BPM to the industrial environment,” said Erik Udstuen, GE Fanuc Software general manager. “As one of the world’s largest and most innovative manufacturers, GE can help companies deliver BPM to production operations and drive three key initiatives: integration– coordinating processes across the enterprise; digitization – driving processes electronically; and finally lean – defining a process improvement framework for business transformation.”

Proficy Workflow permits the improvement, elimination, and automation of steps in production to lean an organization, decreasing time-to-value on materials, speeding response, lowering TCO, and ensuring sustainability. It combines manual and automated work processes without custom code, allowing production experts to solve problems at once, with no demands on IT. Built on an SOA platform, it integrates information and services on a Plant2Enterprise basis, and enables the integration of business and production processes across systems and departments for repeatable process execution.

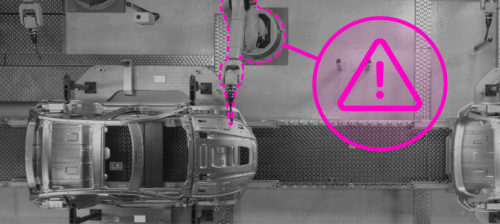

The software provides for the integration of people and their functions or roles, allowing for customization to individual work styles and decision making. As an industrial BPM solution, it takes a production flowchart and digitizes it, connecting people, materials, equipment, and systems involved in the work process. The industrial workflow operates in a time window of seconds and subseconds. Users can digitize a process that involves one or many steps; workflow can take place in one station with one user or spread across the plant and move from person to person.

“A key tool that will enable today’s plants and factories to realize [the] strategy for operational excellence is the ability to define the process or workflow steps required to achieve a logical execution path,” said research director Craig Resnick, ARC Advisory Group. “Proficy Workflow appears to meet this criteria of a tool that will help move manufacturers, processors, and OEMs to a single environment where the existing systems are connected and interacting with each other to maximize the information value of each asset, which will positively impact plant and factory productivity and profitability.”

Greg Millinger, Workflow/SOA product manager for GE Fanuc, added, “Proficy Workflow enables companies to achieve a responsive, data-driven, event-based production management strategy. By digitizing processes with industrial workflow, users can capture process, traceability, and quality data, drive lean initiatives based on factual information, and close the loop for production improvement.”Control Engineering research provide more on how

MES Closes Information Gap.

– Control Engineering News Desk

Register here and scroll down to select your choice of eNewsletters free .

Do you have experience and expertise with the topics mentioned in this content? You should consider contributing to our CFE Media editorial team and getting the recognition you and your company deserve. Click here to start this process.