Service offerings expand from automation distributors

Today’s automation distributors offer more than warehouses full of the latest gadgets, providing a diversity of services to ease buying, installation, start-up, and more.

Distributors in the industrial automation industry have traditionally stocked their warehouses with all the latest technology from the vendors they represent so as to facilitate sales to local clients. With exclusive territories delineated by their vendor partners, distributors have prospered by charging a mark-up on every product sold nearby. This business model, born in the last century, still helps clients obtain hardware, software, and replacement parts on short notice.

Distributors in the industrial automation industry have traditionally stocked their warehouses with all the latest technology from the vendors they represent so as to facilitate sales to local clients. With exclusive territories delineated by their vendor partners, distributors have prospered by charging a mark-up on every product sold nearby. This business model, born in the last century, still helps clients obtain hardware, software, and replacement parts on short notice.

Critics argue that the advent of Internet storefronts and improvements in shipping and logistics make the local-warehouse function obsolete. A distributor that adds no other value to a client’s automation projects simply drives up the cost.

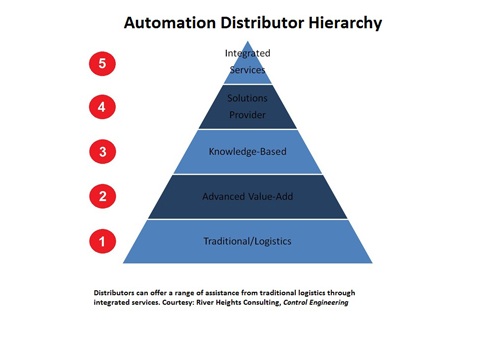

So in recent years, some automation distributors have been making an effort to earn their keep in other ways that enhance the products they sell or improve their clients’ purchasing experience. See the “Distributor evolution” graphic on the next page. The Association for High Technology Distribution (AHTD) now recognizes a class of members known as “Automation Solution Providers” (ASP) that sell technology-based industrial automation products, and

- Knowledge

- Design and application engineering

- Support services

- Integrated solutions

- Value-added services.

These services include programming, customer training, demonstration rooms and equipment, post-order product service and warranty support, and start-up assistance.

Not just product sales

Brian Fisher, president and CEO of Pacific Technical Products, sees his ASP firm as something of a cross between a traditional distributor and a system integrator, though “we actually put in a lot more up-front time during the design phase of the project to help select the right product for the application, and then we end up reviewing everything with the customer once the detailed product list is complete.”

Doing so reduces the chance of a mismatch between the capabilities of the products purchased and the requirements of the project at hand. “Products typically fail where they’re misapplied,” said Fisher, and it is an ASP’s job to prevent those failures much the same way a pharmacist prevents medical failures that could result from the misapplication of a prescription drug.

Rick Gehring, president and CEO of ASP Applied Controls, elaborated: “We help manufacturers and machine builders design and implement technology solutions to reduce costs throughout their processes and protect their automation investments for the long run.” He cited some of the challenges that an ASP can help clients address:

- Maintenance demands from complex control schemes and constantly changing software

- Difficulty lowering lifecycle costs and generating expected returns

- Complying with changing regulatory and safety concerns

- Rising costs due to rapidly evolving technologies

- Reducing and managing energy consumption.

Some ASPs and ASP-like distributors have moved even further into the design and installation fields that traditionally have been the purview of automation system integrators—level five of the “Automation distributor hierarchy.” For example, “Zeller Technologies is one of the few distributors in the nation that provides a full range of services as well as parts,” said Zeller’s automation controls manager, Tom Rudloff.

“We do high-level automation system engineering, installation, and start-up, along with field service troubleshooting on any system in industry. Our techs have been in almost every type of manufacturing process out there,” Rudloff said.

Conflict with system integrators

These expanded service offerings can be a mixed blessing, especially when a distributor counts both end users and system integrators as clients. End users no doubt appreciate the additional technical services that a distributor can bring to bear on their automation projects, but system integrators often see those services as a competitive threat.

Unfortunately, system integrators must still buy products from their designated distributor to incorporate into their own automation projects, leaving them in the awkward position of patronizing their competition. One conflicted integrator voiced his concerns rhetorically in a post to the discussion list of the Control System Integrators Association (CSIA): “For the distributors that have internal SI capability: How do you attempt to manage the inherent conflict when bidding against your SI customer for SI services? How do you handle hardware and software pricing on projects that are bid against SI customers? Why do you maintain an SI capability that competes with your SI customers? Why should I buy anything whatsoever from a competitor?”

Judging from the number of distributors getting into the system integration business, these competitive conflicts are likely to become even more common. See the “Distributors offering system integration services” chart on the next page.

Cooperation, support

On the other hand, many system integrators and distributors enjoy a mutually beneficial relationship. See the sidebar, “Integrators and distributors can work together" on the next page. And according to Viktor Tadjer, general manager of Kibernetika & Co. OOD, distributors today really can’t afford to stay out of the system integration business entirely.

“I find it very rare when we have sold a PLC or some HMI device without any additional engineering. My opinion is that distributors of control systems equipment should have at least average skills for integrating and/or commissioning the equipment they sell. Otherwise, many problems arise because of expensive errors in specifications and the resulting deliveries,” Tadjer said.

Some distributors recognize this need and still find ways to cooperate with their system integrator clients. “With our overlapping role as a products distributor and small integration service provider, said Brenden Fritz, president of Automated Drive Systems, “we focus on distribution and integration of small machine level systems that typically are smaller than a large integration company’s focus.”

Laurie Hall, president of Martindale Associates, takes a similar approach. “We can help with the installation for clients if the project is small, but for a project over $5K that’s very custom, or one that will take several weeks or months, we typically call in a large integrator,” Hall said.

Cooperative competition also affects the relationships that system integrators have with the vendors that their distributors represent. See “System integrators partner with automation suppliers,” linked below.

– Vance VanDoren, PhD, PE, is contributing content specialist for Control Engineering. Reach him at ControlEng@msn.com. Edited by Mark T. Hoske, content manager, CFE Media, Control Engineering, Plant Engineering, and Consulting-Specifying Engineer, mhoske@cfemedia.com.

Online

See "System integrators partner with automation suppliers" linked below.

www.automateddrives.com

www.ptpcorp.com

See more about automation distributor types below with graphics:

Automation distributor types: Logistics vs. projects

Frank Hurtte

What we have observed is an evolutionary split in distributor services. One type of distributor became an expert in the logistics of the moving parts and providing just what the customer wants without heavy investment in technical services. These distributors provide the same products but work to make the transaction side of buying easier. They have invested in websites, automated part number selection schemes, and industrial vending machines (over 21,000 installed in 2012). Examples include Grainger, MSC, Fastenal, and AutomationDirect. They have no local level expertise (except phone support) and depend on customers knowing precisely what they want and offering a lower price point for the product.

What we have observed is an evolutionary split in distributor services. One type of distributor became an expert in the logistics of the moving parts and providing just what the customer wants without heavy investment in technical services. These distributors provide the same products but work to make the transaction side of buying easier. They have invested in websites, automated part number selection schemes, and industrial vending machines (over 21,000 installed in 2012). Examples include Grainger, MSC, Fastenal, and AutomationDirect. They have no local level expertise (except phone support) and depend on customers knowing precisely what they want and offering a lower price point for the product.

The other branch of the distributor evolution contains distributors who have opted for a more hands-on selling approach. They are serving customers by assisting in selection of products, maintaining the products, and pushing forward—things like drive start-ups, programming assistance, architecture layout, troubleshooting, and in some instances, project work.

These distributors have developed services like training, control architecture design, and communications layouts, which often exceed others in the market. Why? They are forced to learn about new technologies ahead of engineering firms and systems integrators because they play the role of trainers to that group as well.

Further, distributors often find themselves on the front lines of “proving things work.” A customer calls and says, “the DeviceNet connection doesn’t work like you promised.” The distributor then goes out and troubleshoots to prove the system works, often discovering undocumented issues along the way.

– Frank Hurtte is the founder of distributor River Heights Consulting. www.riverheightsconsulting.com

Integrators and distributors can work together

Todd Carswell

Maintaining a good relationship with our main distributor has been an integral part of our success. Twenty years ago we looked to our distributors to carry a parts inventory and that was all. Because of this attitude, a lot of big distributors (and even some smaller ones) in the 1990s moved to centralized warehouses with very little inventory at the local level. In some cases, they closed down their supply house and opened a sales office only. Some went so far as to cut back on their technical staff as well, relying on the manufacturers to supply technical support.

Today, some of the distributors still have this mind-set. Ours has gone the other direction, and because of this, they receive the bulk of our electrical purchases. On the inventory side, they’ve not only raised their inventory levels at the supply house to meet our demands, they also manage and run our inventory here. This saves a tremendous amount of time on our side.

We also look to them for our technical needs. The local branch has specialists for variable frequency drives (VFDs), programmable logic controllers (PLCs), human-machine interfaces (HMIs), and other areas. These people spend a lot of time helping with design questions and service questions and setting up training sessions, at their shops and at ours.

– Todd Carswell is vice president of technical services at system integrator Vecoplan LLC. www.vecoplanllc.com

Automation distributor services

The services provided by modern automation distributors can be arranged in a hierarchy where each level builds on the levels below. Higher levels also involve more technical skills and greater involvement with a client’s automation projects.

1. No fee-based services. Customer technical needs other than manuals and front line questions are pushed to manufacturers.

2. Limited fee-based services, typically centered on classroom training and custom modifications of product

3. Classroom training, one-on-one engineering assistance, drive start-up, system wide layouts

4. Training, troubleshooting, start-up, and product specific programming; piecemeal project integration

5. Training, troubleshooting, start-ups, complete project integration.

Key concepts

- Distributors can go beyond offering the latest technologies to provide buying, installation, start-up, and other services.

- Automation distributor services build on each other

- Integrators and distributors can work together

Consider this

Are you getting what you need from your distributors? If not, why not?

Do you have experience and expertise with the topics mentioned in this content? You should consider contributing to our CFE Media editorial team and getting the recognition you and your company deserve. Click here to start this process.