Partners at last

The signs are encouraging. After several decades, it's finally happening. Maintenance is taking its rightful place as a true business partner in the industrial enterprise. I've come to this conclusion by what I've witnessed over the past few years.

The signs are encouraging. After several decades, it’s finally happening. Maintenance is taking its rightful place as a true business partner in the industrial enterprise. I’ve come to this conclusion by what I’ve witnessed over the past few years.

Check, for example, this issue’s focus panel on “Foundations for Maintenance Excellence.” Our panel members were universal in their opinions that maintenance had to be aligned with their plants’ business strategies.

Over the years, this alignment has been a problem from several standpoints. Most obvious was the maintenance department’s blind insistence that maintenance was important for its own sake, even though the business case for maintenance was poorly defined. Lacking any convincing business case, operations and financial people treated maintenance as a necessary evil with little relevance to productivity or profitability.

But all parties are beginning to understand that maintenance is not just a necessary cost of business, it’s an opportunity to reduce life-cycle costs, ensure capacity, and even provide a competitive edge. In short, it’s a partner in business improvement.

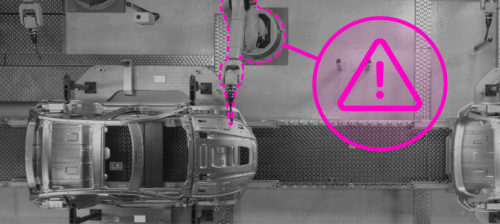

A strong indicator of the shift taking place is the repositioning going on in the industrial software business. A decade ago, software developers weren’t much interested in trying to integrate CMMS data with the other systems plants were using – like financial systems, MRP programs, and manufacturing automation. Now, that integration is at the top of their lists of features.

Large companies are finding it valuable to bring together their maintenance people from all their plants to share ideas and practices. These meetings are typically multiday proprietary technical conferences, complete with concurrent sessions, general sessions, and an occasional outside speaker.

Some plants these days will even send maintenance personnel to work with customers to help solve their machinery and production problems. Both parties gain from the shared experience and knowledge.

These are all good signs and good practices. The door is finally opening to the maintenance function as a full partner in optimizing the plant’s business.

So now there’s a new challenge to maintenance to make good on the opportunity and to expand it’s influence. The need for proven performance and excellence in maintenance has never been greater.

Do you have experience and expertise with the topics mentioned in this content? You should consider contributing to our CFE Media editorial team and getting the recognition you and your company deserve. Click here to start this process.