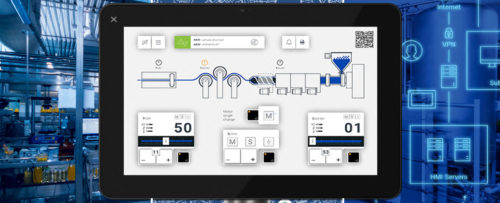

Industrial automation software suite

PAC Project 9.2

PAC Project 9.2 is an upgrade to the PAC Project suite of software applications and utilities that provide control programming, HMI development, OPC connectivity, and database integration. PAC Project is part of the SNAP PAC System, an integrated system of hardware and software for industrial control, energy management, remote monitoring, and data acquisition applications. A key addition in this PAC Project upgrade is support for several recently released SNAP I/O modules.

Opto 22

Do you have experience and expertise with the topics mentioned in this content? You should consider contributing to our CFE Media editorial team and getting the recognition you and your company deserve. Click here to start this process.