Alarm management life cycle provides process insight

Alarm management can simply be defined as “efficient handling of alarms.” However, this statement has a different meaning to different people.

Alarm management can simply be defined as “efficient handling of alarms.” However, this statement has a different meaning to different people. For a process operator, alarm management means “seeing alarms only relevant to him at any given time.” For a control engineer, it means “speed at which alarms are generated, notified, distributed and stored.” And for a plant manager, it could mean “effective notification and distribution of alarms in addition to efficient alarm history retrieval.”

To understand alarm management, we need to understand the “life cycle” of an alarm. The “life cycle” of an alarm is divided into the following stages:

-

Alarm generation

-

Alarm notification and distribution

-

Alarm acknowledgement

-

Alarm escalation and re-alarming

-

Alarm storage

-

Alarm changes

-

Alarm history retrieval and reporting.

-

Each of these stages caters to distinct alarm behaviors and can be managed in a variety of ways.

Alarm generation

The generation stage is the brain behind the total alarm management system. Detection of a new alarm, escalation of an existing alarm or regeneration of an active alarm contributes to the alarm generation stage.

An effective alarm generation engine is one that provides the flexibility of categorizing alarms, prioritizing alarms and defining the different types of alarms. The right combination of alarm categories, priorities and types can provide the maximum capability for the generation engine to detect alarms and at the same time allow the filtering of nuisance alarms that ensures users see only those alarms that matter. Alarm generation can also be coupled with alarm suppression and alarm inhibition to reduce noise and nuisance signals.

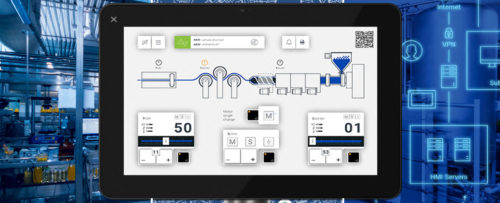

Alarm notification, distribution

The notification and distribution stage is the transport and user interface layer of the alarm management system. The goal of this layer is to ensure that the concerned user gets the alarm information — wherever he or she is — in a timely manner. This could involve transmitting alarms across networks, modems, public address systems, annunciators, horns or phones. Lately, alarm notification through e-mail, SMS, MMS, pagers and cell phones are gaining popularity.

To ensure that the notification and distribution is effective, it is important that the system allows dividing the total alarms into sets of accountability for the users. This way, users see only alarms that they are responsible for, and can take action on — thus, increasing the effectiveness of — alarm responses and actions. Another aspect of alarm notification is triggering Standard Operating Procedure or workflow templates that provide guidance to users regarding actions they need to take in certain situations.

Alarm acknowledgement

Alarm acknowledgement is a simple basic function of the alarm management system, but the tracking of alarm acknowledgments is a critical part to every alarm analysis. Also, a flexible alarm notification must be supported by an equally flexible alarm acknowledgement. Alarm acknowledgement in modern day alarm management systems must support remote acknowledgement — across the network or over the phone.

With regulatory requirements necessitating that users record the trail of alarm interactions, alarm acknowledgement must support security, electronic signatures and audit trails to be submitted with regulatory and validation reports. The accountability feature of alarm notification must be coupled with security for alarm acknowledgement to be effective, and to ensure that the right people are taking the actions. Alarm acknowledgement efficiency can be increased by providing flexibility to acknowledge multiple alarms based on functional area, alarm category, alarm type and alarm priority.

Alarm escalation, re-alarming

The alarm escalation and re-alarming stage is one of the most important parts of an alarm management system. This stage combines the functionality of the alarm generation and alarm notification stages, except it deals with already existing active alarms.

In a SCADA system, which deals with numerous alarms, the alarm escalation and re-alarming stage ensures that users do not miss out on important alarms or alarm changes. Any active alarms — acknowledged or unacknowledged — can easily be overlooked depending on the size of the SCADA system. This stage ensures that any alarms, which have moved to a higher severity or have not been looked at for some time, will go through alarm generation and notification. This ensures that these alarms again get precedence and have a better chance of being looked at.

Alarm storage

The storage of alarms has come a long way in SCADA systems. From traditional flat files to relational databases and alarm historians, there are various solutions available today. The key to an effective alarm storage pool is the flexibility it provides to the alarm generation engine to route its alarms.

The speed at which the alarm storage pool can accept alarms from the alarm generation engine and the buffering it provides to temporarily store the overflowing alarms defines the authenticity of the alarm storage. For any SCADA user, the fact that “no alarms are missed” while transitioning from alarm generation to alarm storage is of primary importance. The concept of central alarm storage is already popular and is widely used in most SCADA applications today. For redundant systems, it is important for alarm storage to recognize the redundancy so no duplicate alarms are generated.

Alarm changes

Along with the management of real time alarm processes, it is also important for alarm management systems to manage any changes done to configured alarms. These changes could mean changing alarm thresholds, changing alarm functional areas, changing alarm security and changing alarm behavior. Any of these changes can modify the content of the alarm management system. It is critical that these changes can be managed, tracked and audited.

A change management system must be an integral part of the alarm management system to help it control alarm changes. More and more HMI/SCADA systems are being shipped with change management systems to help users in disaster recovery and auditing their systems. The best alarm management systems use change management to detect and track changes and also store these changes for later retrieval and analysis.

Alarm history retrieval, reporting

Alarm history retrieval and reporting is the analysis stage of any alarm management system. The value of an alarm management system depends largely on the analysis tools that the system provides. Sequence of events/alarms, alarm behavior and frequency of alarms are some of the key alarm analytical tools. Alarm reporting involves audit trails of alarms, intrusion alarm reports, alarm suppression reports and alarm inhibit reports.

Complex alarm analytics can involve studying the behavior of users on certain alarms: alarm generation versus alarm acknowledgement response times, and navigation time from alarm detection to alarm action. A very effective tool is the use of graphics replay type functionality that plays back the situation at the time of the alarm to provide users with some insight of what the conditions might have been.

Also, the ability to trend historical values with alarms provides users with the insight of a cause-and-effect analysis. With change management systems being popular with HMI/SCADA systems, new alarm analytical tools to correlate alarm occurrences with alarm changes are also gaining popularity.

As users try to gain insight into their processes to gain productivity and profitability, effective alarm management systems are becoming the need of every analysis.

Author Information Prasad Pai is the HMI/SCADA product manager at GE Fanuc Intelligent Platforms. Looking in on the Automation Federation

The Automation Federation Board of Directors will engage in its third annual strategic planning session in April to discuss the accomplishments, developments and future plans of the umbrella organization. The Federation members WBF, OMAC, WINA and ISA have been focused on the critical industry issue of workforce development. Toward that end, the Federation has started to establish a strong footprint in Washington, D.C. as the voice of automation.

“The vision for the Federation has been met and exceeded in the past year, and this transition gives us an opportunity to refresh and update our strategy so that we can catch up to our accomplishments,” said Automation Federation chairman Steve Huffman. “The board is looking forward to continuing to serve both the member organizations and the broader objectives of the Federation.”

The member organizations of the Automation Federation have experienced areas of growth recently. ISA has been an active participant in the Automation Federation’s government relations initiatives, with ISA leaders welcoming North Carolina Representative David Price to AF headquarters in February. ISA has also defined several initiatives in an ongoing workforce development plan, working in conjunction with the other organizations of the Federation.

OMAC’s Microsoft Manufacturing User Group (MsMUG) is migrating to the Automation Federation to better support industry needs as a horizontal application that sprawls across the vertical disciplines. End-users and integrators join MsMUG to have an opportunity to be part of one manufacturing voice. Moving the working group to the Automation Federation will broaden participation and establish a communication channel into the manufacturing space relative to process, hybrid and discrete industry segments.

WBF’s North American Conference, held March 24-27 in Philadelphia, boasted the “highest quality selection of presentations and papers that we’ve ever had,” according to WBF chairman Maurice Wilkins.

WINA will join with ISA to coordinate the technical program for the 2008 Industrial Wireless Conference in Chongqing, China, March 31-April 4. The event represents a worldwide collaboration of leading organizations, with the Chongqing University of Posts and Telecommunications hosting. At the end of 2007, WINA announced that it will create its first chapter outside North America. Based in Singapore, the chapter will serve the Asia Pacific region.

“We have a lot of exciting work going on in the member organizations and in the Federation as a whole, and that pace will only get faster after we’ve had a chance to meet in April and clarify our strategy and goals for the future of the organization,” said Huffman.

ARC forum to tackle Asset Lifecycle Management

ARC Advisory Group will conduct its first Asset Lifecycle Management Forum on Oct. 13-15 in Houston. Plant Engineering is a media sponsor of this forum.

This event will bring together stakeholders and suppliers to discuss how better Asset Information Management can help them optimize performance in every asset lifecycle stage. Companies will learn how AIM impacts asset performance while networking with others to discuss common issues.

ALM is important to manufacturing leaders who depend on complex equipment. These leaders must keep an eye on revenue, safety, compliance, quality and operating cost problems that arise when performance in operating plants is not optimized.

“ARC’s research shows that collaboration and teamwork across all asset stakeholders is vital to ensuring good AIM,” said Sid Snitkin, vice president and general manager of ARC’s Enterprise Advisory Services. “Each group needs to appreciate the impact their practices have on asset performance and align their practices and goals to achieve optimal performance.”

Key topics for ARC’s ALM Forum include:

Learn about the “hidden ways” that AIM impacts asset performance

Gain the knowledge to identify significant “hidden costs” in your AIM program

Discover what leading companies are doing to overcome cultural, contractual and infrastructure roadblocks that frustrate collaborative programs

Understand what technology suppliers are doing to enable you to improve AIM

See what industry and standards groups are doing to enable better information interoperability.

For more information about ARC’s Asset Lifecycle Management Forum, go to

Do you have experience and expertise with the topics mentioned in this content? You should consider contributing to our CFE Media editorial team and getting the recognition you and your company deserve. Click here to start this process.